VC SERIES

EN0H-0327GE25 R0206 2 Honeywell • All rights reserved

Specifications

Medium Water or water-glycol mixture

(max. 50% glycol content),

quality to VDI 2035

pH-value 8...9.5

Operating temperature 1...95°C (34...203°F)

120°C (248°F) short duration

peak

Ambient temperature max. 65°C (149°F)

Operating pressure max. 20 bar (290 psi) static

max. 100 bar (1,450 psi) burst

Differential pressure max. 4 bar (58 psi)

k

vs (cv)-values see chapter “Dimensions” below

Flow 2-way: flow can be in either

direction. When actuator is not

mounted valve is in closed

position

3-way: bottom port is marked

AB. End ports are marked A and

B. When actuator is not

mounted port A is closed.

Voltage 24 V, 50-60 Hz (blue label)

200-240 V, 50-60 Hz (red label)

Power consumption 4 VA

(when valve position changes)

Auxiliary switch rating 1.0 A @ 250 V, 50-60 Hz

(minimum 0.05 A @ 24 Vdc)

Nominal timing Valve opens in 7 seconds

(20% faster for 60 Hz)

Electrical termination 1. Molex™ socket: requires

mating connector,

alternatively

2. With integral 1 m leadwire

Shipping temperature -40…65°C (-40…149°F)

Humidity rating 5…95% RH (non-condensing)

Atmosphere non-corrosive, non-explosive

Function

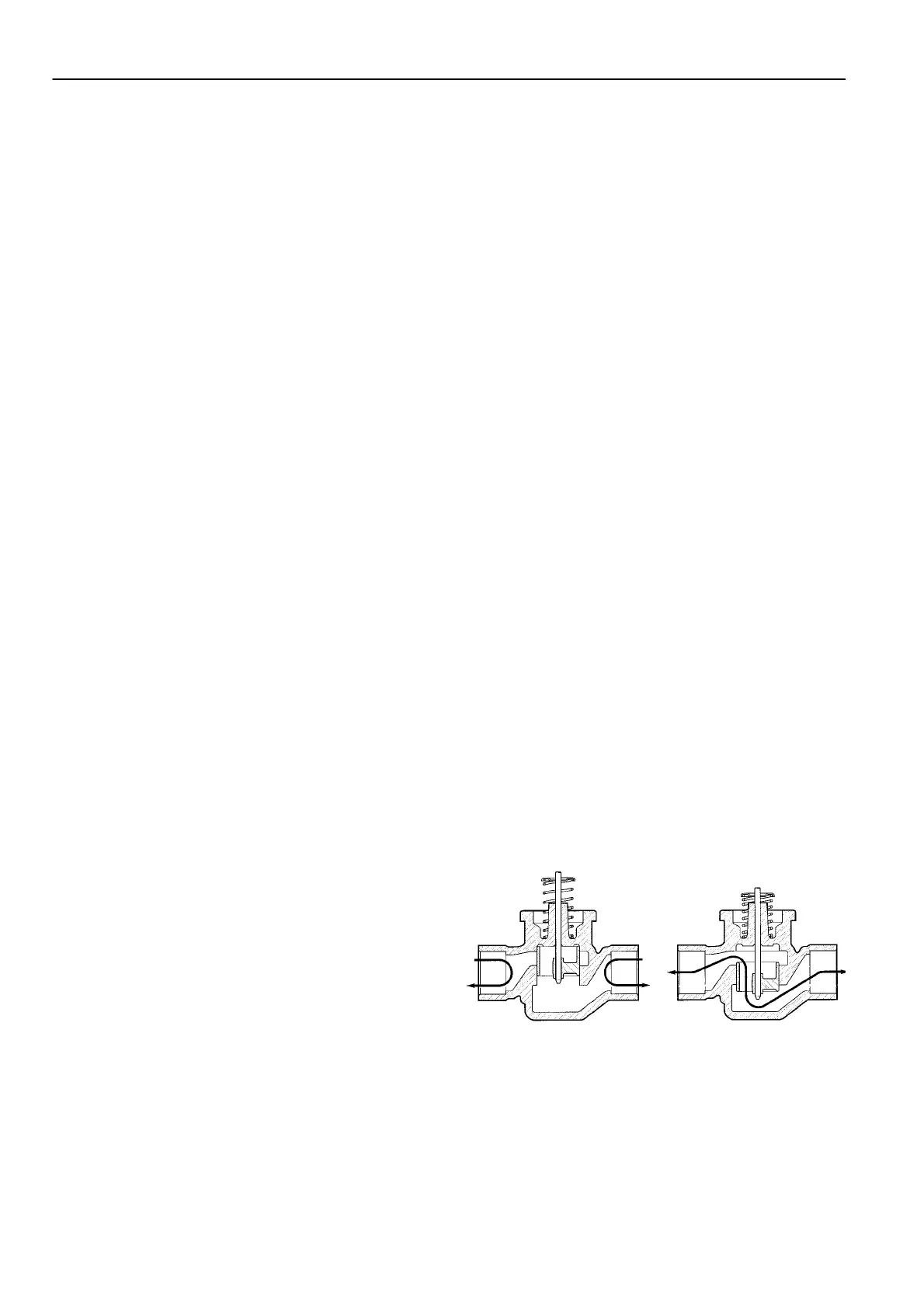

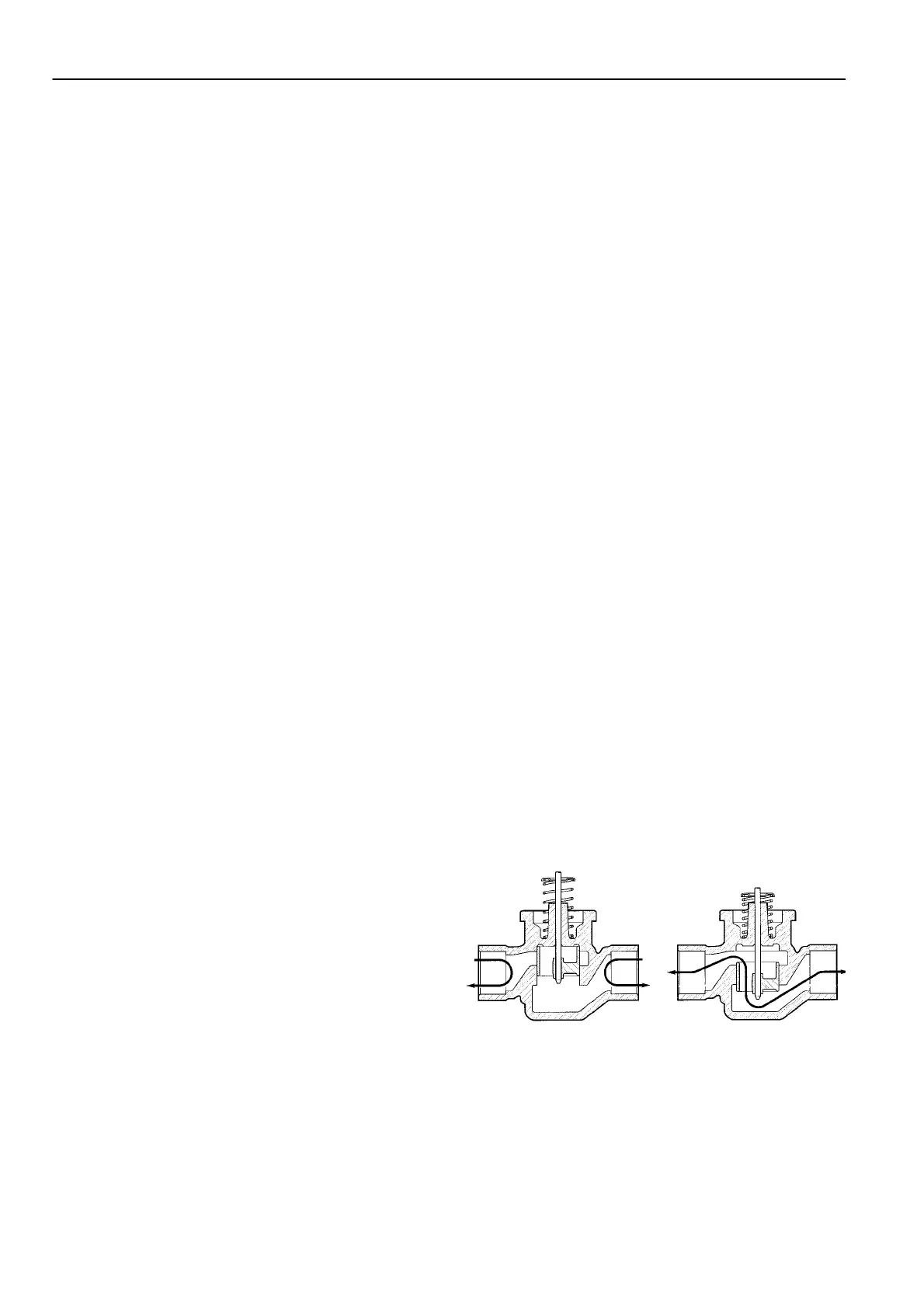

VC Series 2-position hydronic valves are used in domestic

and small commercial applications to control the flow of hot

and/or cold water. They consist of an actuator, valve and a

cartridge assembly.All moving and sealing parts of the valve

are constructed in the cartridge assembly. The ports are

sealed with O-rings on the outer surface of the piston.

When the valve stem is driven down to open port A the water

will flow through the hollow piston to the other port. In case of

a 3-way valve with the piston driven down port B is sealed,

allowing flow between port AB and port A. With the stem up

the flow is between port AB and port B.

The valve family offers a variety of versions of pipe connecti-

ons to suit the different applications. The valve pressure loss

characteristic is dependent on the pipe connections/ dimensi-

ons. For the actual valve rating please refer to the specificati-

on section.

2-way valve

With an SPDT (3-wire) actuator

On a call for heat, the NO controller contacts close and the

valve opens. When the valve is fully open, the cam closes

switch SW1 and opens switch SW2. When the need for heat

is satisfied the NC controller contacts close, energising the

valve through SW1 and closing the valve. When the valve is

fully closed, the cam closes SW2 and opens SW1. The valve

is ready for the next call for heat.

With an SPST (2-wire and common) actuator

On a call for heat, the controller contacts close, RLY1 is e-

nergized making the NO contacts in switch SW3 causing the

valve to open. When the valve reaches the fully open position

the cam closes switch SW1 and opens switch SW2. When

the need for heat is satisfied, the controller contacts open,

RLY1 is de-energized and the valve motor is driven through

SW1 and the NC contacts of SW3. When the valve reaches

the fully closed position, the cam closes SW2 and opens

SW1. The valve is ready for the next call for heat.

For both types of actuator a power failure will leave the valve

at the position it was when interrupted. When power is resto-

red, the valve will respond to controller demand.

Fig. 1. Fluid flow through 2-way VC valve

Loading...

Loading...