HONEYWELL

HONEYWELLHONEYWELL

HONEYWELL

CLASS “A” COMBINATION VALVES

VQ400M-Series

EN2R9081-C

October 2009

11

ADJUSTMENTS AND FINAL

CHECKOUT

The procedures described in this chapter are

related to the adjustments on the main gas valve,

pilot valve and by-pass valve. For adjustments on

the other additional functionalities (e.g. pressure

switch), refer to the included instruction sheet of the

product in question in the package.

CAUTION

• Adjustments must be made by qualified

personnel only.

• To ensure a safe closing of the valves, it is

essential that voltage over the terminals of

operators is reduced to 0 Volts.

2

nd

main valve fast opening

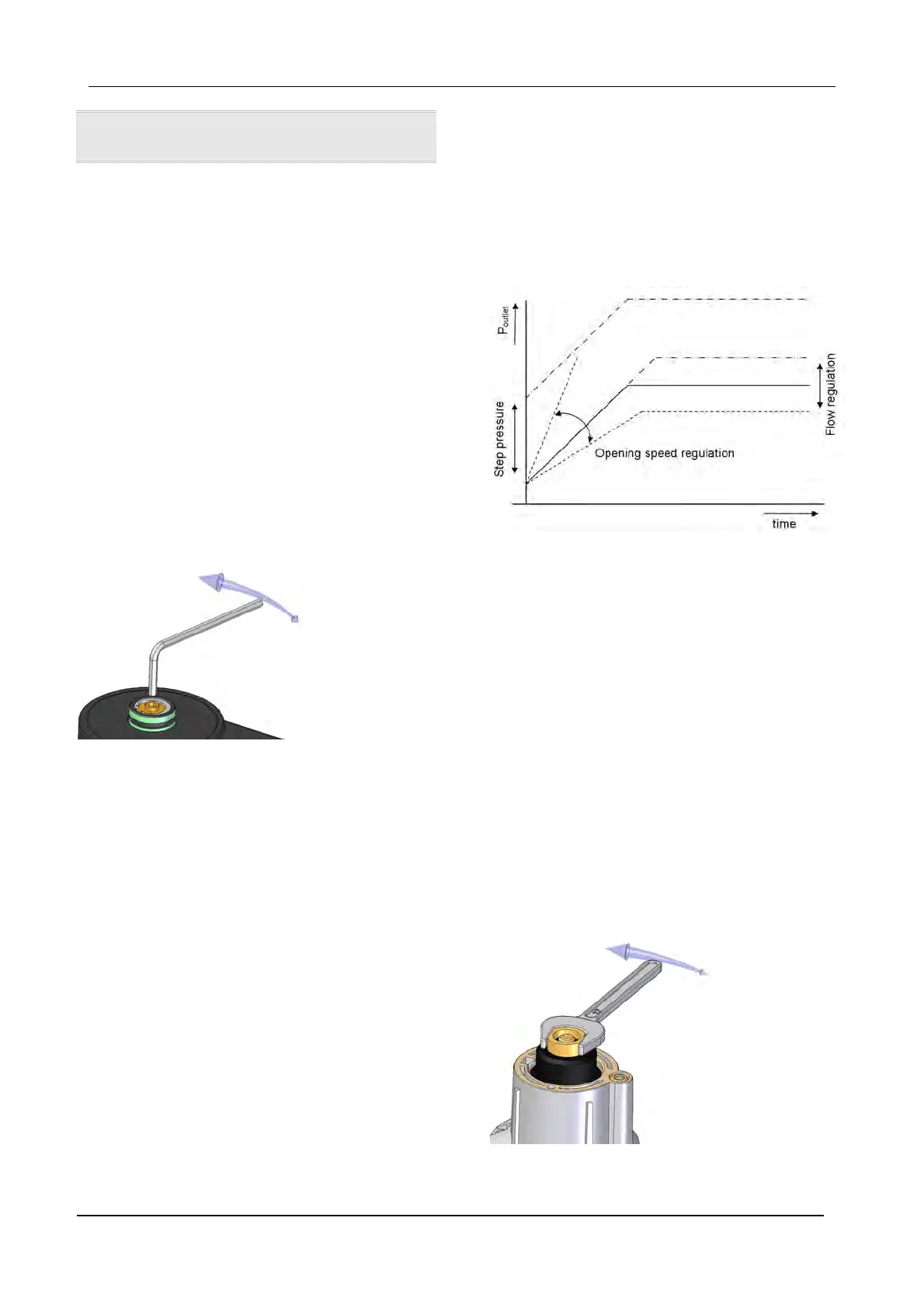

Figure 9 Adjusting flow rate.

Flow rate adjustment (see Fig. 9.)

1. Remove the cap screw from top of the coil.

2. Place a socket head wrench into the

adjustment nut.

3. Turn wrench counter-clockwise to increase

or clockwise to decrease flow rate.

4. Replace cap screw.

2

nd

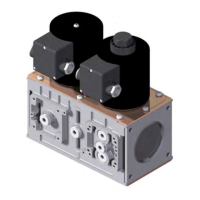

main valve slow opening

The following characteristics can be adjusted:

• flow rate

• step pressure

• opening speed

Figure 10 Characterized opening.

IMPORTANT

To ensure a satisfactory setting of the valve the

pressure drop over the valve should be at least

10% of the supply pressure or 2.5 mbar which ever

is the greatest.

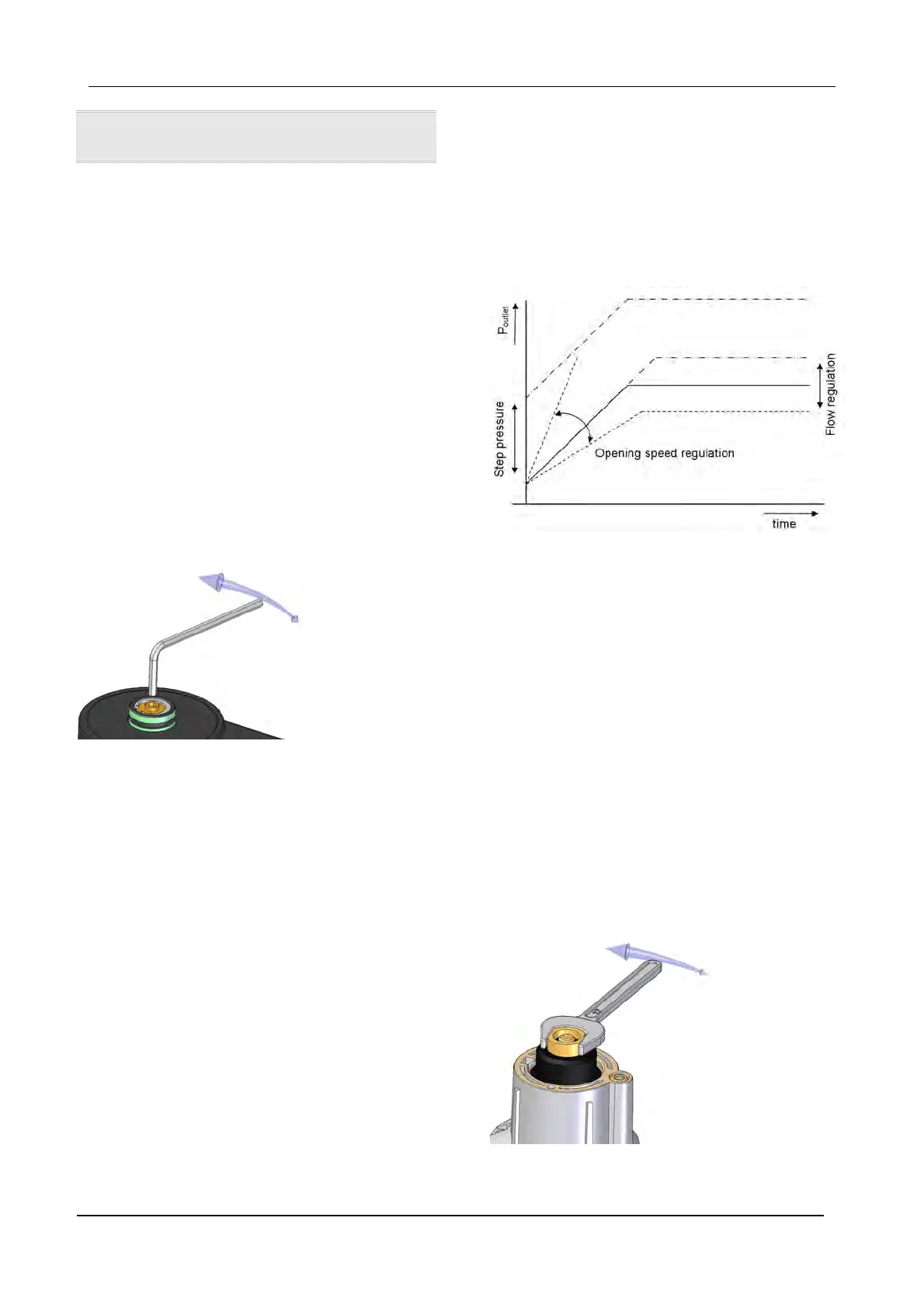

Flow rate adjustment

1. Remove the cap from top of the coil by

loosening both screws.

2. Place a wrench on the adjustment hexagon

nut.

3. Turn wrench counter-clockwise to increase

or clockwise to decrease the flow rate.

4. Replace cap on top of the coil.

Figure 11 Adjusting flow rate.

Loading...

Loading...