HONEYWELL

HONEYWELLHONEYWELL

HONEYWELL

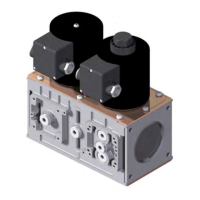

CLASS “A” COMBINATION VALVES

VQ400M-Series

EN2R9081-C

October 2009

2

CONTENTS

VQ400M SERIES ........................................................... 1

CLASS “A” COMBINATION VALVES ......................... 1

APPLICATION................................................................ 1

Contents ......................................................................... 2

FEATURES .................................................................... 2

DESCRIPTION............................................................... 3

SPECIFICATION ............................................................ 3

Models ........................................................................ 3

Dimensions ................................................................. 3

Pipe sizes.................................................................... 4

Capacity...................................................................... 4

Connections................................................................ 4

Torsion and bending stress......................................... 4

Supply voltages........................................................... 4

Electrical equipment.................................................... 4

Electrical connections ................................................. 5

Ambient temperature range ........................................ 5

Coil insulation solenoid valves .................................... 5

Enclosure.................................................................... 5

Body material.............................................................. 5

Closing spring ............................................................. 5

Valve plunger.............................................................. 5

Seals and gaskets....................................................... 5

Power consumption .................................................... 5

PERFORMANCE CHARACTERISTICS......................... 6

Opening time............................................................... 6

Closing time ................................................................ 6

Maximum working frequency ...................................... 6

Duty cycle ................................................................... 6

Operational voltage range........................................... 6

Designed life time ....................................................... 6

CAPACITY CURVES...................................................... 7

INSTALLATION.............................................................. 8

IMPORTANT............................................................... 8

WARNING................................................................... 8

Maintenance and service............................................ 8

Mounting position........................................................ 8

Mounting location........................................................ 8

Main gas connection flanged valves ........................... 9

WARNING!.................................................................. 9

Electrical connection................................................... 9

WARNING................................................................... 9

Wiring.......................................................................... 9

ADJUSTMENTS AND FINAL CHECKOUT .................. 11

CAUTION.................................................................. 11

2

nd

main valve fast opening....................................... 11

2

nd

main valve slow opening ..................................... 11

IMPORTANT............................................................. 11

Final checkout of the installation............................... 12

OPTION INSTALLATION ............................................. 13

WARNING................................................................. 13

CONSTRUCTION AND WORKING PRINCIPLES........ 13

ORDERING INFORMATION ........................................ 14

NOTE........................................................................ 14

Replacement of parts.................................................... 15

Warning..................................................................... 15

Recommended accessories ......................................... 15

APPROVALS................................................................ 17

Declaration of Conformity.......................................... 17

FEATURES

• Class “A” safety combination valve for

control of gaseous fluids in gas consuming

appliances in accordance with international

standards.

• Main body with two gas valves with single

seat.

• Possibility of installing internal by-pass

valve to achieve high-low flame control.

• Possibility of installing internal or external

pilot valve.

• Possibility of installing vent valve.

• Possibility of installing flanged minimum

and maximum pressure switches.

• Possibility of installing valve Proving

System (VPS).

• Possibility of mounting Closed Position

Indication switch (CPI) at bottom of safety

valve V1 and / or valve V2.

• Closing time: < 1 second.

• Coils field replaceable.

• Coils suitable for permanent energizing.

• Fine mesh screen between inlet flange and

main body (optional).

• Various pressure tap points at main body

available

• Second main valve, either with adjustable

flow regulator (fast), or characterized

opening mechanism (slow) with adjustable

maximum flow rate and step pressure.

• Rectifier boards field replaceable.

• PG11 cable strain relief standard at

VQ400M.

• Plug connector according to ISO 4400 /

DIN EN 175301-803 optional for VQ400M.

Loading...

Loading...