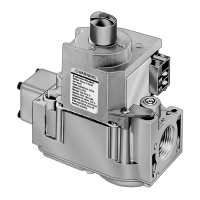

Install Gas Control

1. This gas control can be mounted 0-90 degrees, in any

direction, including vertically, from the upright position of

the gas control knob.

2. Mount the gas control so gas flow is in the direction

of the arrow on the bottom of the control.

3. Thread pipe the amount shown in Table 4 for inser-

tion into the gas control. DO NOT THREAD PIPE TOO

FAR. Valve distortion or malfunction may result if the pipe

is inserted too deeply into the gas control.

TABLE 4—NPT PIPE THREAD LENGTH IN

INCHES.

Maximum Depth

Pipe Can Be

Pipe Thread Pipe Inserted Into

Size This Amount Control

3/8 9/16 3/8

1/2 3/4 1/2

3/4 13/16 3/4

4. Apply a moderate amount of good quality pipe

compound (do not use Teflon tape) to pipe only, leaving

two end threads bare. On LP installations, use compound

resistant to LP gas. Refer to Fig. 5.

5. Remove seals over gas control inlet and outlet if

necessary.

4

Fig. 5—Use moderate amount of pipe compound.

Fig. 4—Install sediment trap.

Fig. 6—Proper use of wrench on gas control with and without flanges

GAS

CONTROL

GAS

CONTROL

HORIZONTAL

DROP

PIPED

GAS

SUPPLY

PIPED

GAS

SUPPLY

3 IN.

(76 MM)

MINIMUM

3 IN.

(76 MM)

MINIMUM

RISER

GAS

CONTROL

TUBING

GAS

SUPPLY

HORIZONTAL

DROP

3 IN.

(76 MM)

MINIMUM

RISER

M3077

2

1

2

2

1

2

ALL BENDS IN METALLIC TUBING SHOULD BE SMOOTH.

CAUTION: SHUT OFF THE MAIN GAS SUPPLY BEFORE REMOVING

END CAP TO PREVENT GAS FROM FILLING THE WORK AREA. TEST

FOR GAS LEAKAGE WHEN INSTALLATION IS COMPLETE.

TWO IMPERFECT

THREADS

GAS CONTROL

THREAD PIPE THE AMOUNT

SHOWN IN TABLE FOR

INSERTION INTO GAS CONTROL

APPLY A MODERATE AMOUNT OF

PIPE COMPOUND TO PIPE ONLY

(LEAVE TWO END THREADS BARE).

M3075B

PIPE

APPLY WRENCH

FROM TOP OR

BOTTOM OF GAS

CONTROL TO

EITHER SHADED AREA

WHEN FLANGE IS NOT USED

APPLY WRENCH

TO FLANGE ONLY

WHEN FLANGE IS USED

M3085A

Loading...

Loading...