TABLE 5—PRESSURE REGULATOR SPECIFICATION PRESSURES IN INCHES WC.

Outlet Pressure

Nominal Factory

Nominal Inlet Setting Setting Range

Type of Pressure Full Full

Model Gas Range Step Rate Step Rate

Standard-, Natural 5.0 - 7.0 — 3.5 — 3.0 - 5.0

Slow-opening LP 12.0 - 14.0 — 10.0 — 8.0 - 12.0

Step- Natural 5.0 - 7.0 0.9 3.5 — 3.0 - 5.0

opening LP 12.0 - 14.0 2.2 10.0 — 8.0 - 12.0

TABLE 6—PRESSURE REGULATOR SPECIFICATION PRESSURES IN kPa.

Outlet Pressure

Nominal Factory

Nominal Inlet Setting Setting Range

Type of Pressure Full Full

Model Gas Range Step Rate Step Rate

Standard-, Natural 1.2 - 1.7 — 0.9 — 0.7 - 1.2

Slow-opening LP 2.9 - 3.9 — 2.7 — 2.0 - 3.0

Step- Natural 1.2 - 1.7 0.2 0.9 — 0.7 - 1.2

opening LP 2.9 - 3.9 0.9 2.7 — 2.0 - 3.0

c. Always replace the cap screw and tighten firmly to

ensure proper operation.

4. If the desired outlet gas pressure or gas flow rate

cannot be achieved by adjusting the gas control, check the

gas control inlet pressure using a manometer at the inlet

pressure tap. If the inlet pressure is in the normal range

(refer to Table 5 or 6), replace the gas control. Otherwise,

take the necessary steps to provide proper gas pressure to

the gas control.

Step-Opening Pressure Regulator

1. The gas control outlet pressure should match the

manifold pressure listed on the appliance nameplate.

2. With the main burner operating, check the gas con-

trol flow rate using the meter clocking method or check the

gas pressure using a manometer connected to the gas

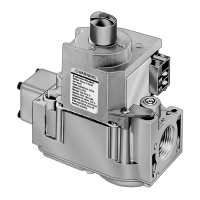

control outlet pressure tap. Refer to Fig. 1.

3. If necessary, adjust the pressure regulator to match

the appliance rating. Refer to Table 5 or 6 for factory set

nominal outlet pressures and adjustment ranges.

a. Remove the pressure regulator adjustment cap screw.

b. Using a screwdriver, turn the inner adjustment screw

clockwise to increase or counter-

clockwise to decrease the main burner gas pres-

sure.

c. Always replace the cap screw and tighten firmly to

ensure proper operation.

4. If desired outlet pressure or flow rate cannot be

achieved by adjusting the gas control, check the inlet

pressure using a manometer at inlet pressure tap or up-

stream of the gas control. If the inlet pressure is in the

normal range (refer to Table 5 or 6), replace the existing gas

control. Otherwise, take the necessary steps to provide

proper gas pressure to the gas control.

5. Carefully check main burner lightoff at the step

pressure. Ensure the main burner lights smoothly and

without flashback to the orifice and that all ports remain lit.

Cycle the main burner several times, allowing at least 30

seconds between cycles for the regulator to resume the step

function. Repeat after allowing main burner to cool. Read-

just the full rate outlet pressure, if necessary, to improve

lightoff characteristics.

CHECK SAFETY SHUTDOWN PERFORMANCE

WARNING

FIRE OR EXPLOSION HAZARD

CAN CAUSE PROPERTY DAMAGE,

SEVERE INJURY, OR DEATH

Perform the safety shutdown test any time work is

done on a gas system.

NOTE: Read steps 1-7 below before starting and compare

to the safety shutdown or safety lockout tests recom-

mended for the direct ignition (DI) module. Where they

differ, use the procedure recommended for the module.

1. Turn gas supply off.

2. Set thermostat or controller above room temperature

to call for heat.

3. Watch for ignition spark or for glow at hot surface

igniter either immediately or following prepurge. See DI

module specifications.

4. Time length of igniter operation. See DI module

specifications.

5. After the module locks out, open gas control and

ensure there is no gas flow to main burner.

6. Set thermostat below room temperature and wait one

minute.

7. Operate system through one complete cycle to en-

sure all controls operate properly.

!

7 69-0626—2

Loading...

Loading...