TR10A108-B RE / 02.2013

43

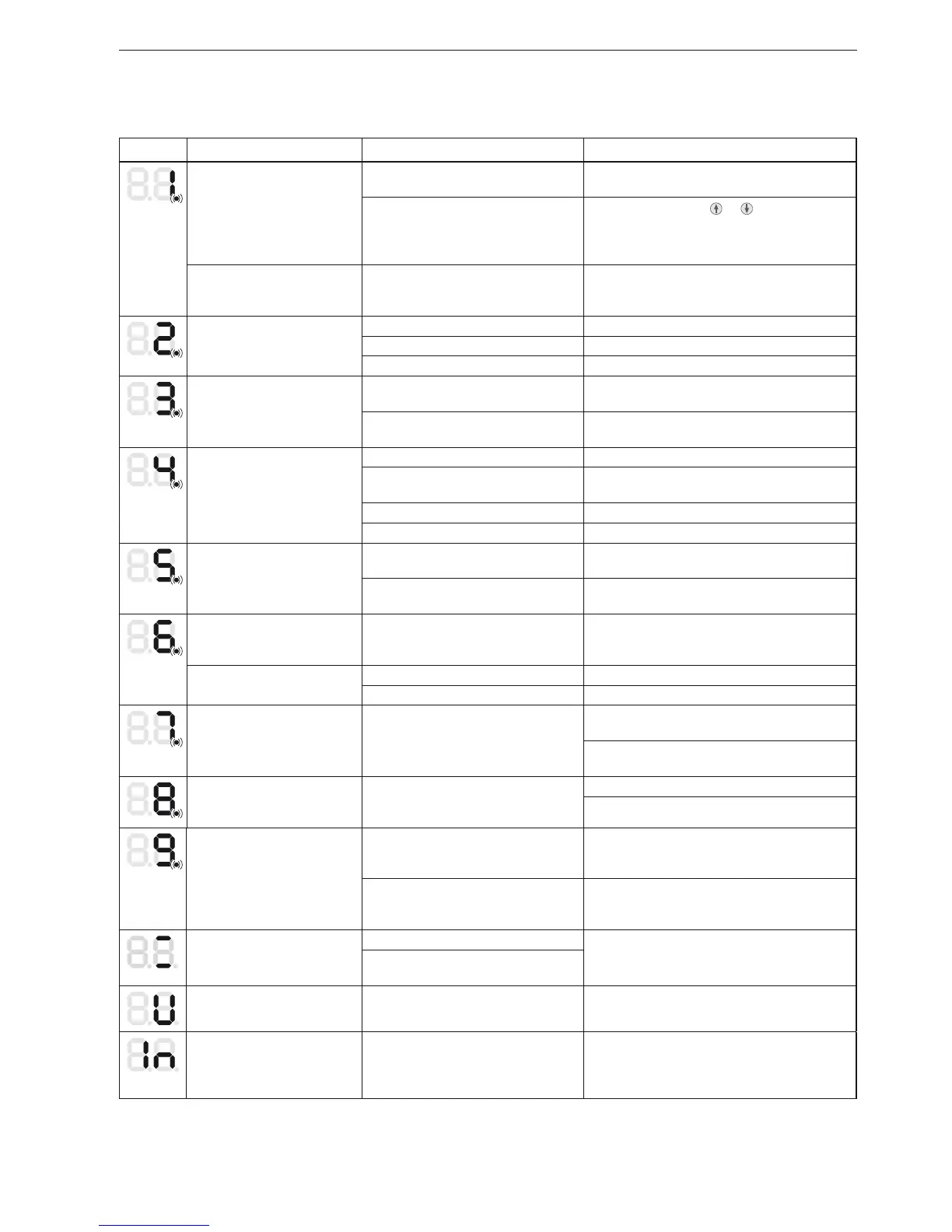

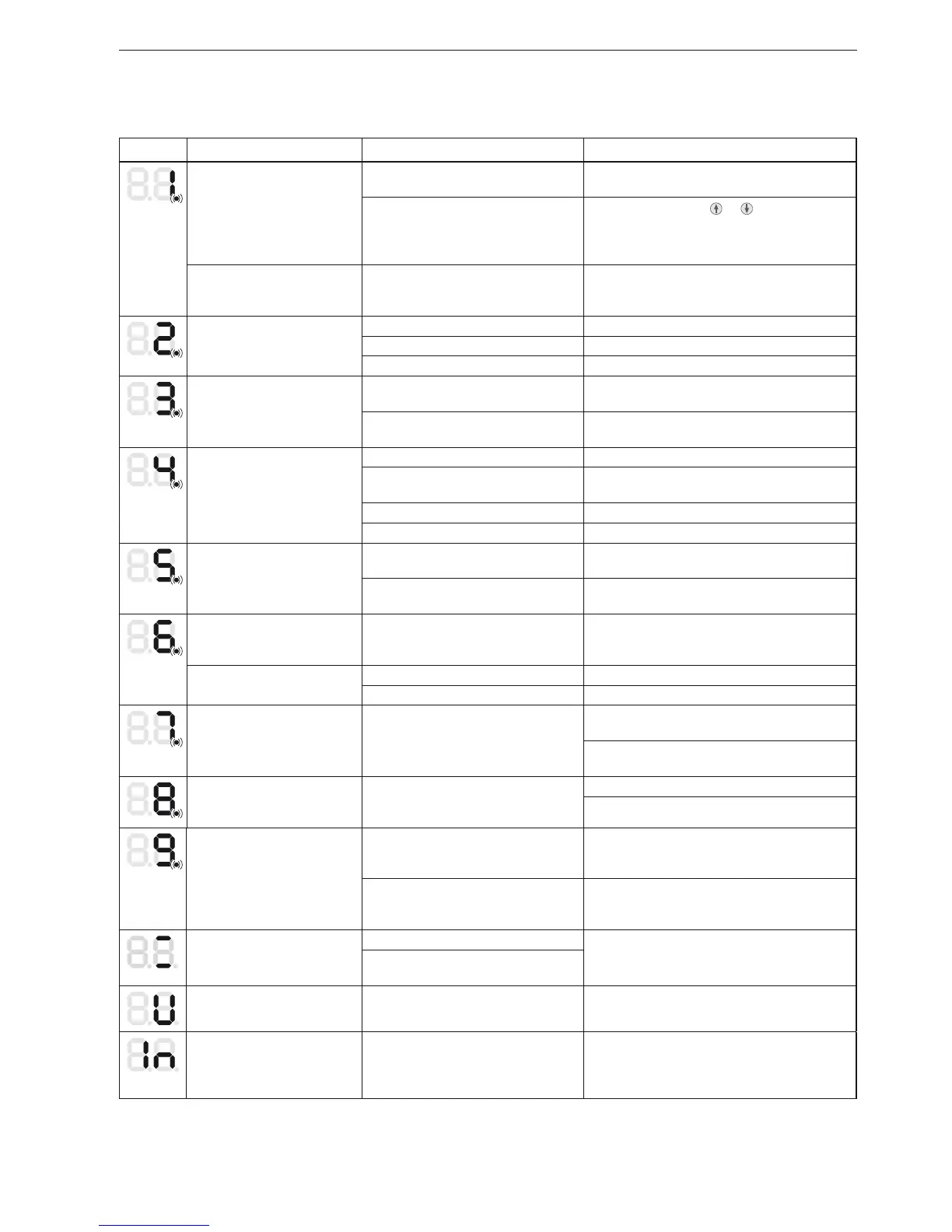

Display of Errors / Warnings and Operating Conditions17

Display of errors and warnings17.1

Display Error / warning Possible cause Remedy

Reversal limit cannot be set An obstacle was in the way when the

SKS / VL reversal limit was set

Remove the obstacle

The position of the reversal limit is

> 200 mm before the Close end-of-

travel position

Pressing the buttons

or acknowledges

the error.

Select a position < 200 mm before the Close

end-of-travel position

Partial opening height

cannot be set

The partial opening height is too

close to the Close end-of-travel

position (≤ 120 mm slide travel)

The partial opening height must be higher

Safety equipment

(photocells)

No photocell is connected Connect a photocell or activate menu 60

The light beam is interrupted Adjust the photocell

The photocell is defective Exchange the photocell

Power limit in Close direction The door is too sluggish or does not

move smoothly

Correct the door travel

Obstacle in door area Remove the obstacle and teach in the

operator again, if necessary

Static current circuit open The wicket door is open Close the wicket door

The magnet has been fitted the

wrong way

Fit the magnet correctly (see the instructions

for the wicket door contact)

The testing result is not OK Exchange the wicket door contact

Stop UAP pressed

Power limit in the Open

direction

The door is too sluggish or does not

move smoothly

Correct the door travel

Obstacle in door area Remove the obstacle and teach in the

operator again, if necessary

System error Internal error Restore the factory setting (see section 12),

teach in the operator again or exchange, if

necessary

Travel time limit The belt is torn Exchange the belt

The operator is defective Exchange the operator

Communication error Communication with the additional

print is faulty (e.g. UAP 1, ES 1,

ES 2, EF 1)

Check the connecting leads and exchange,

if necessary

Check the additional print and exchange,

if necessary

Travel command not

possible

The operator has been blocked for

the control elements and a travel

command was given

Release the operator for the control elements

Check the connection of the IT 3b

Closing edge safety device The light beam is interrupted Check the transmitter and receiver and

exchange, if necessary, or exchange the

complete closing edge safety device

8k2 resistance contact strip

is defective or not connected

Check the 8k2 resistance contact strip or

connect to the operator via the 8k2-1T

decoder unit

No reference point Power failure Move the door to the Open end-of-travel

position

Power limit has been triggered 3 ×

in a row in the Close direction

The operator has not been

taught in

The operator has not been taught in

yet

Teach in the operator (see section 5)

Maintenance display flashes

during each door run.

No error

The maintenance interval set by the

fitter has been exceeded.

Have the door system inspected and

maintained by a qualified person in

accordance with the manufacturer's

specifications.

ENGLISH

Loading...

Loading...