230 Chapter 5 Print Quality

Print Quality

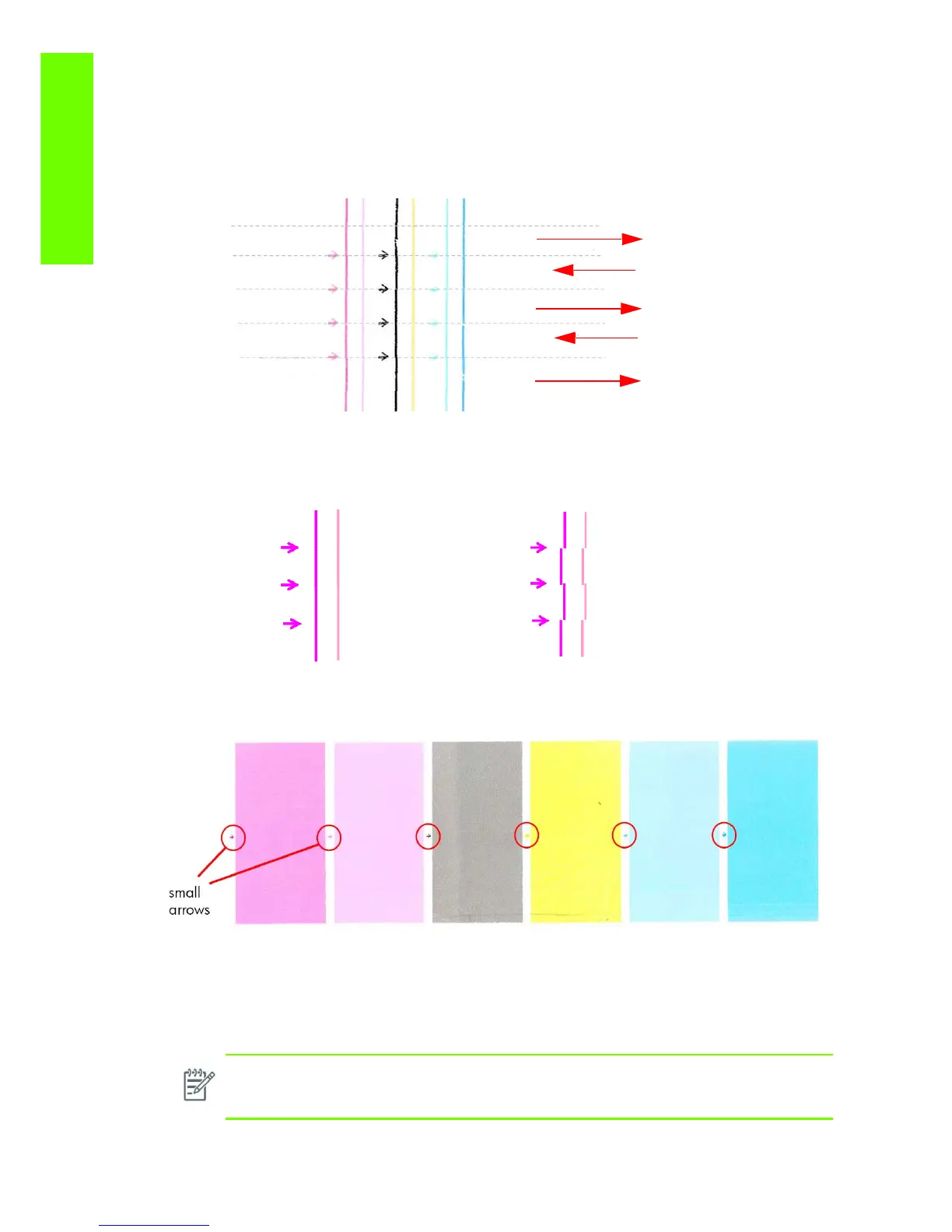

2. Scan Axis Bidirectional check

The small arrows point to the place where lines printed in forward and reverse directions meet. It is at this

point that the registration accuracy must be checked.

The check should be done for the M-Lm, KY and C-Lc printheads. The bidirectional alignment can change

slightly as the substrate thickness varies.

The plot should show lines perfectly aligned with each other, a straight vertical line indicates correct

bidirectional alignment (A). If any of the printheads are experiencing bidirectional misalignment issues,

the alignment test will print the lines as show below (B).

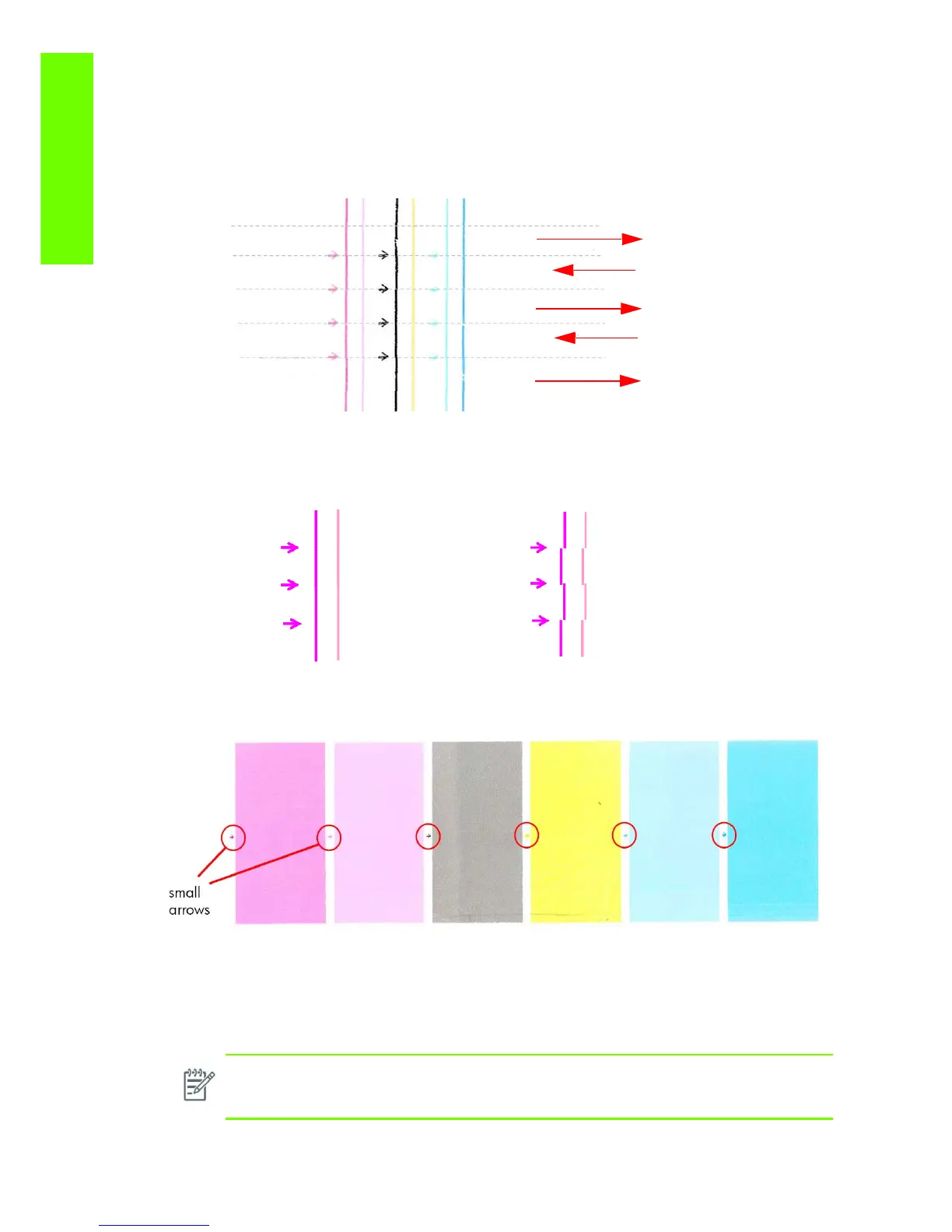

3. Nozzle check and Paper Axis Die to Die Registration

The colors are printed with a halftone, low-ink area fill, in a one pass printmode.

The small arrows point to the place where two different printhead dies meet. No significant light or dark

lines should be seen at this point. Manual Alignment reset the alignment back to factory defaults.

The patches also provide a basic judgment about the printhead nozzle status. Horizontal bands indicate

weak or missing nozzles.

NOTE: If there are many horizontal bands indicating weak or missing nozzles, the die to die

registration test will be a poor indicator of the status of the die to die registration. If this occurs

clean the printheads and reprint the test.

Loading...

Loading...