460 Chapter 9 Preventive Maintenance

Preventive Maintenance

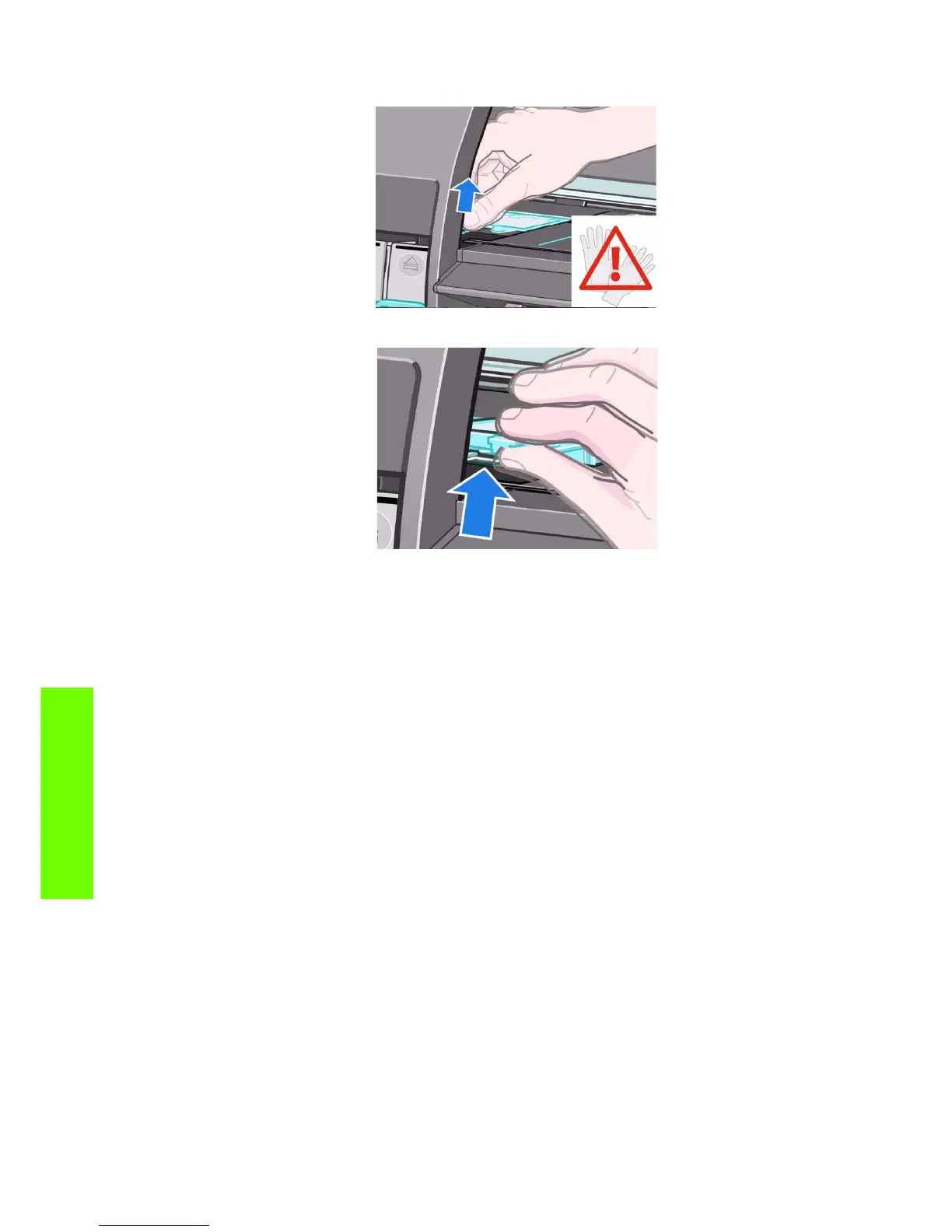

7. Lift the tab on the absorber until it is clear of the spittoon and you can easily grip the tab.

8. Lift and remove the absorber from the spittoon.

9. Dispose of the soiled maintenance absorber according to your local regulations.

Insert the maintenance absorber

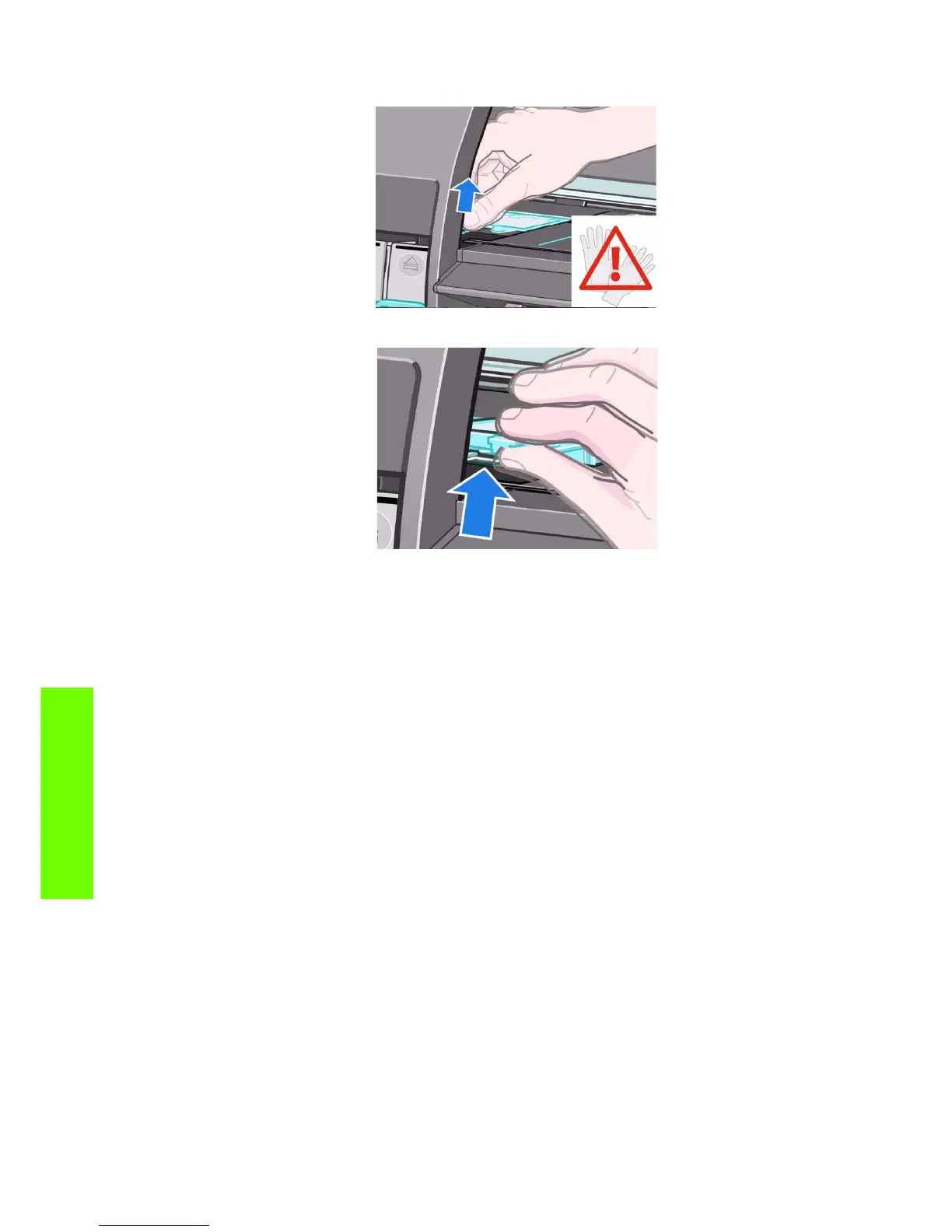

1. Grip the new maintenance absorber as shown.

2. Insert the back edge of the absorber into the fitting in the spittoon.

3. Use your thumb to slide the absorber to the back of the fitting in the spittoon.

4. Push down on the tabbed edge until you hear the absorber click into place. Make sure that the top

of the maintenance absorber is seated flatly and that none of the corners are higher than the plane

of the platen.

5. Press the OK button on the front panel. The printer verifies that the maintenance absorber is correctly

seated. If the front panel shows a message that it is not seated correctly, remove the maintenance

absorber, insert it again, and then press the OK button.

Scheduled Maintenance

In some segments of the printer market, the customer tends to print more than the maximum number of

prints that the throughput allows, exceeding by far the limit of the design. When this happens the customer

runs into print quality problems and continuous Printer failures.

The purpose of scheduled preventive maintenance is to avoid these failures - ensuring a good performance

during all the product life.

Level of Printer Usage

Normal printer use means 6,000,000 Carriage Cycles (which corresponds to approximately 100,000

A0 prints on average). Under normal usage conditions, it will be approximately 5 years before the printer

needs maintenance. If the printer is used more than the normal usage conditions, then it will need

maintenance service much more frequently.

One of the EEROM counters is assigned to counting the number of carriage cycles. When certain

components of the Printer exceed this amount, the front panel displays the following message:

Loading...

Loading...