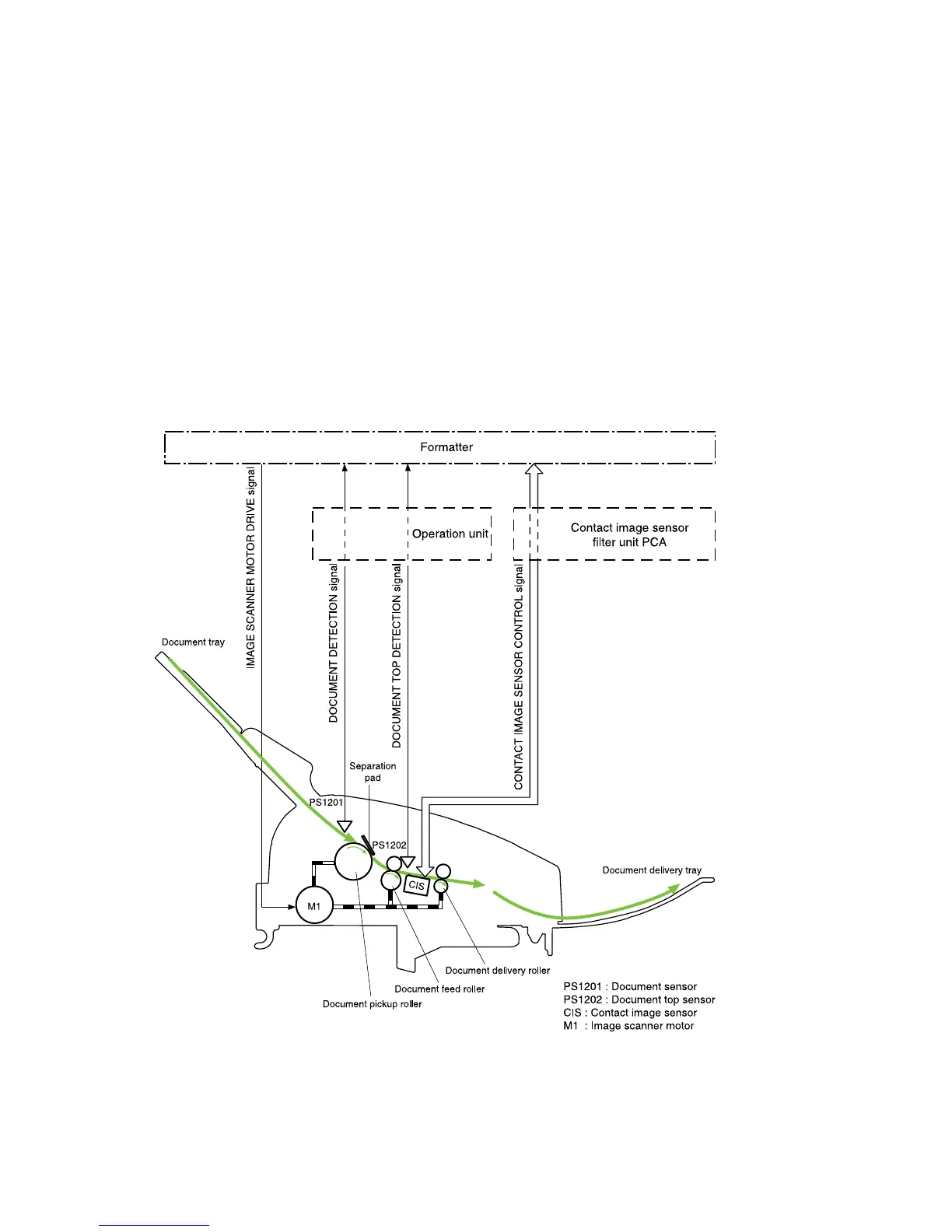

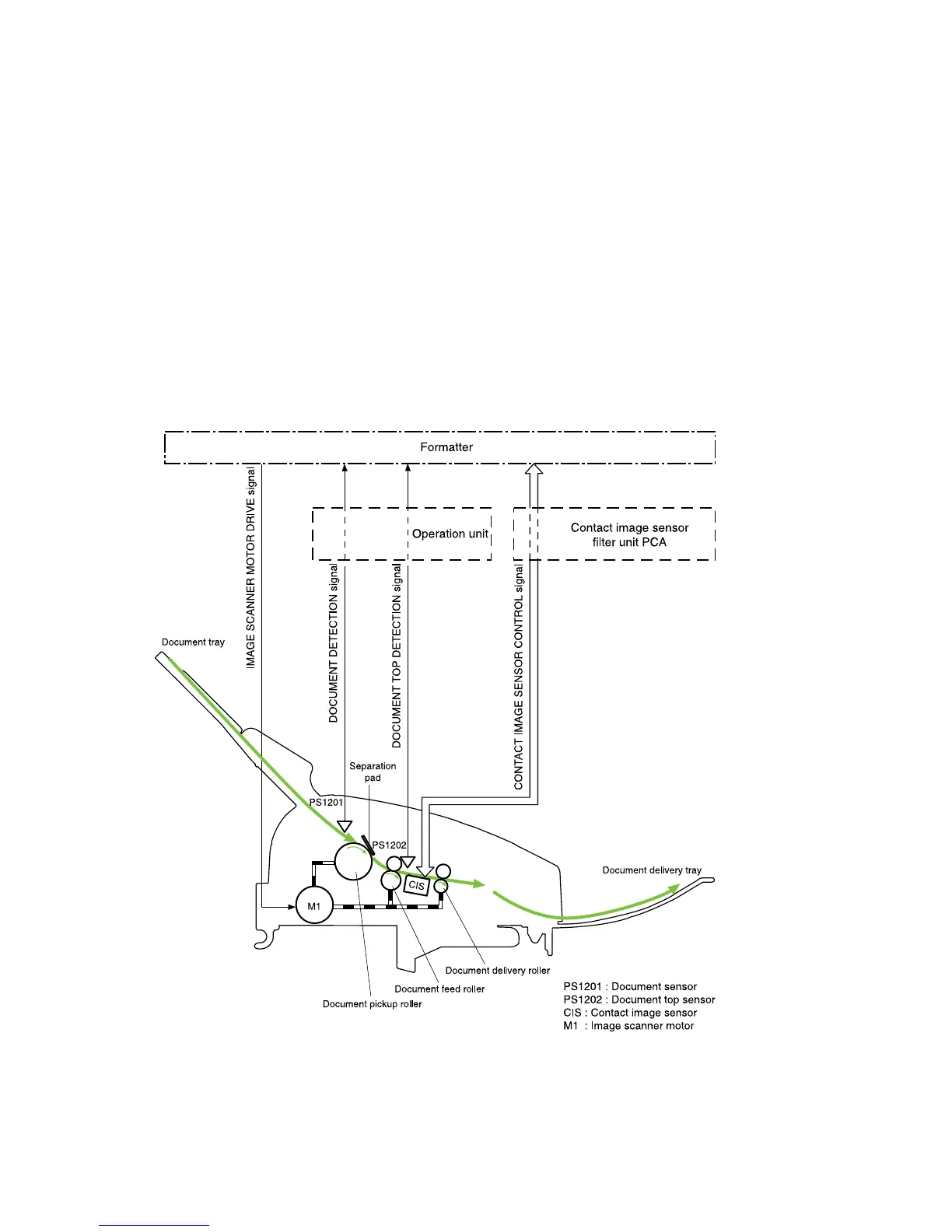

ADF pickup-and-feed system

The ADF pickup-and-feed system uses a pickup roller, a feed roller, and a delivery roller to transport

the document into, through, and out of the optical scanning system. The optical scanning system motor

drives the rollers when the formatter signals the optical scanning system that a job to print or copy is

present.

The ADF pickup-and-feed path has two sensors. The document sensor (PS1201) detects the presence

of a document in the ADF input tray. The document-top sensor (PS202) detects the document in the

ADF paper path. The formatter processes the signals from the sensors and the product operates

accordingly.

When the contact image scanner motor rotates, it causes the pickup, feed, and delivery rollers to rotate.

The ADF document pickup roller pushes a document into the ADF paper path. The separation pad

prevents multiple pages from entering the ADF paper path by creating friction against the document and

the pickup roller. The document feed roller advances the document past the contact image sensor (CIS).

The document delivery roller advances the document out of the ADF paper path to the output area.

Figure 5-9 Feed control (1 of 2)

The contact image scanner motor drives the pickup roller, the feed roller, a one-way clutch, and the

delivery roller. A gear differential causes the pickup roller to rotate at a slower speed than the feed roller.

The slower speed allows for a consistent space between pages of a multiple-page document, which is

54 Chapter 5 Operational theory ENWW

Loading...

Loading...