Any changes in rolling effort or unusual noises must be immediately identified and corrected

WARNING

14

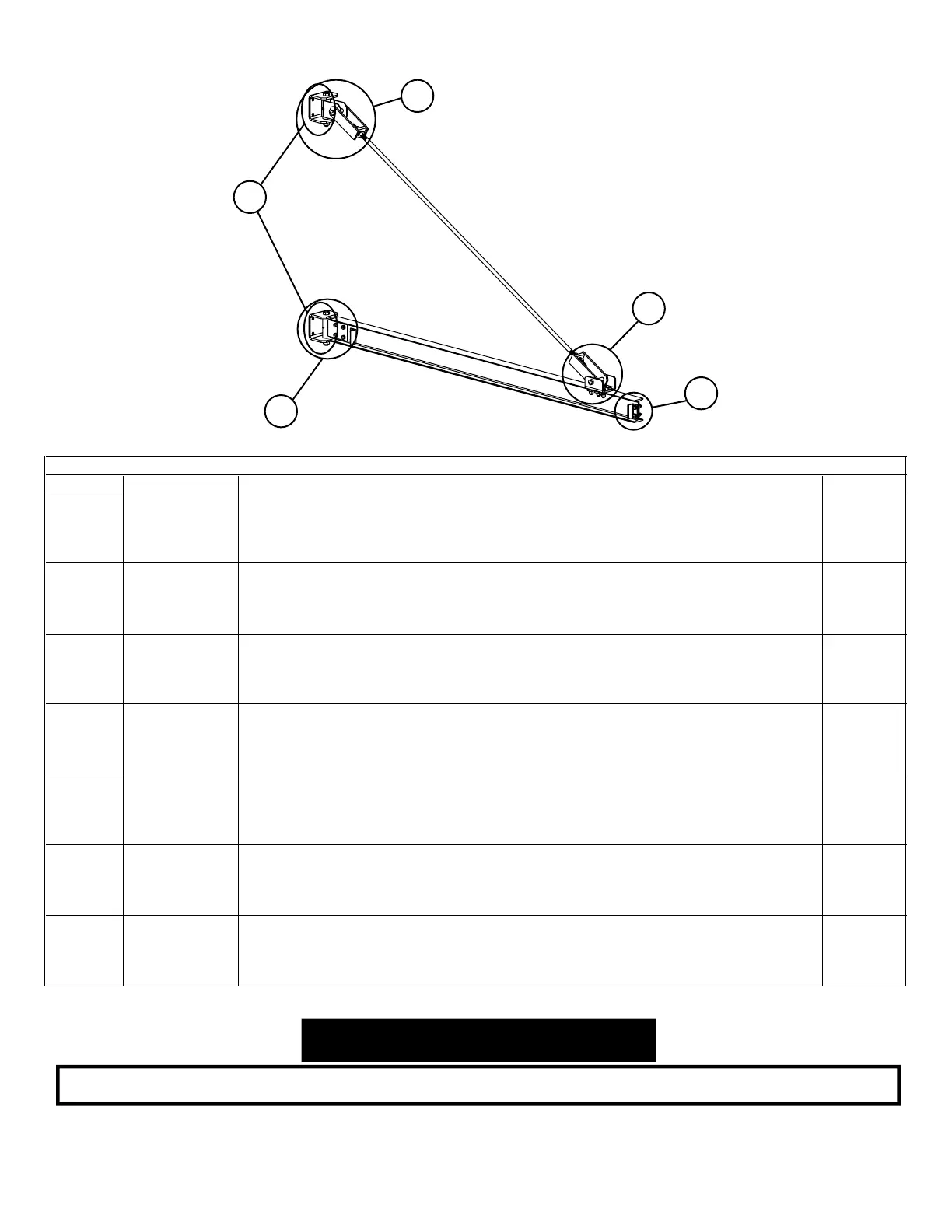

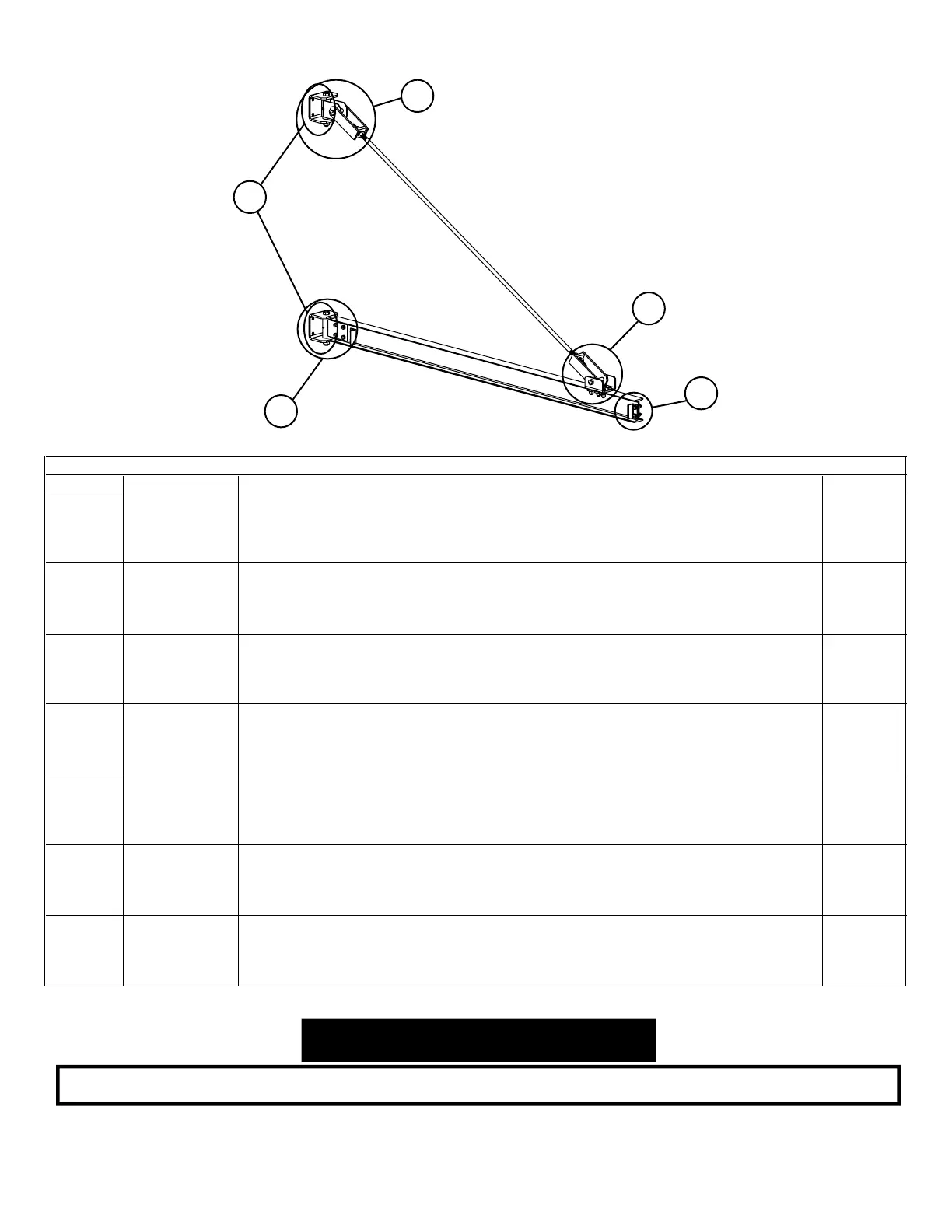

Figure No. Item Inspection Frequency

1 Mounting Bolts

Check that the lock-washers are fully compressed and the nuts are tightened to

manufacturer’s specifications.

Every 500

hours

Or 3 months

2

Upper Fitting

Assembly

Check that the lock-washers are fully compressed and the nuts are tightened to the proper

torque specs from

Table 1

. Make sure cotter pin is securely fastened into fitting pin hole.

Make sure fittings are well lubricated per

Page 5

and locked into place.

Eve

ry 500

hours

Or 3 months

3

Lower Fitting

Assembly

Check that the lock-washers are fully compressed and the nuts are tightened to the proper

torque specs from

Table 1

. Make sure cotter pin is securely fastened into fitting pin hole.

Make sure fittings are well lubricated per

Page 5

and locked into place.

Every 1000

hours

Or 6 months

4

Boom End Fitting

Assembly

Make sure cotter pins are securely fastened into fitting pin hole. Make sure fittings are well

lubricated pe

r

Page 5

. Check that the lock-washers are fully compressed and the nuts are

tightened to the proper torque specs from

Table 1

.

Every 500

hours

Or 3 months

5

End Stop/Tight

Wire Kit

Check that the lock-washers are fully compressed and the nuts are tightened to the proper

torque specs from

Table 1

.

Every 500

hours

Or 3 months

- Additional Items Conduct a general inspection of all additional items you may have purchased.

Every 1000

hours

Or 6 months

- General

Conduct a visual inspection of

the overall crane and check any operator reports. If any flaws

or problems are found, the crane should be taken out of service and reported to manufacturer

immediately.

Every 1000

hours

Or 6 months

Crane Inspection

2

1

3

4

5

Loading...

Loading...