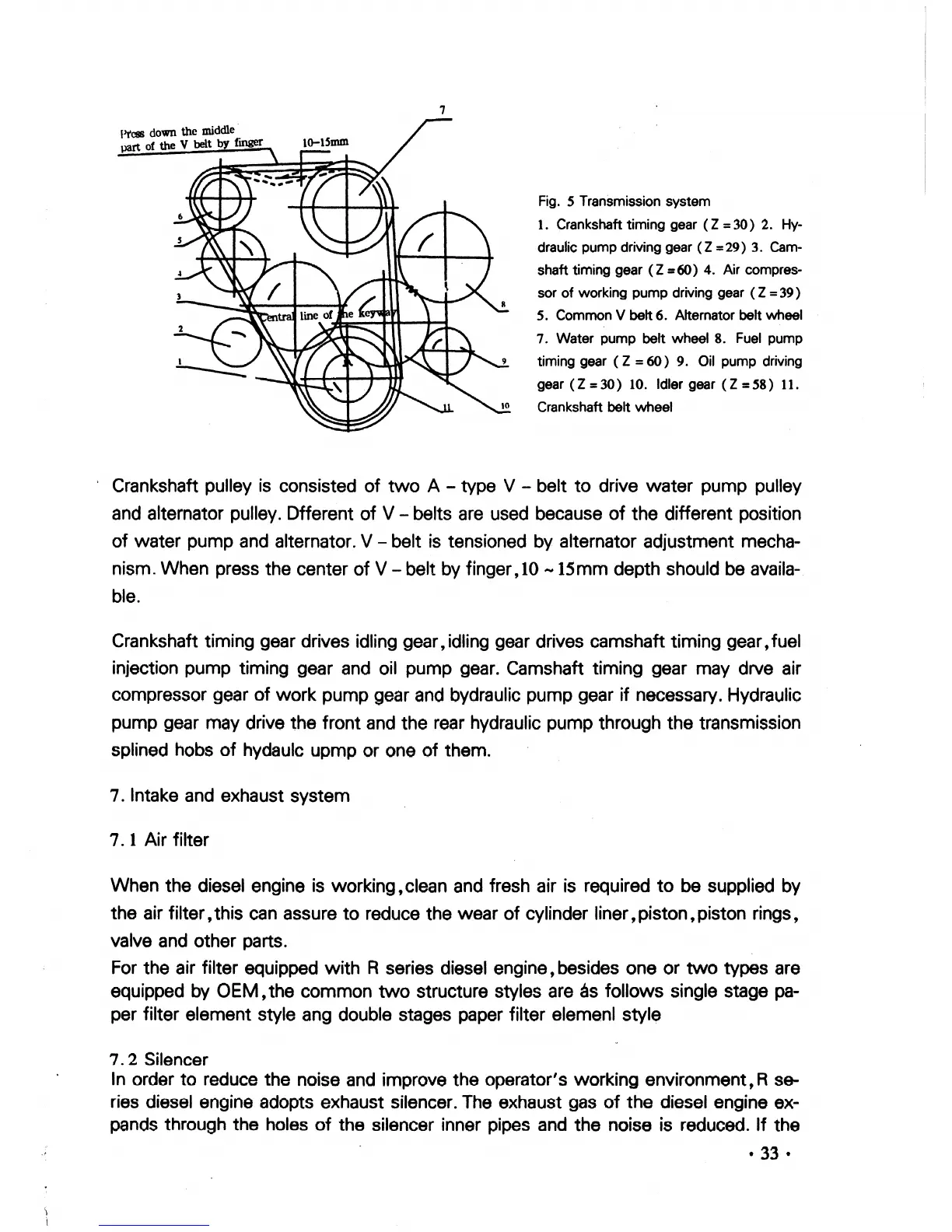

7

PrC91

down the middle -

part

of

the V belt by finger

Fig.

5 Transmission system

1.

Crankshaft timing gear

(Z

=30)

2.

Hy-

draulic pump driving gear

(Z

=

29)

3.

Cam-

shaft timing gear

(Z

=60)

4.

Air compres-

sor

of

working pump driving gear

(Z

=

39

)

5.

Common V belt 6. Alternator belt wheel

7.

Water pump belt wheel

8.

Fuel

pump

timing gear

(Z

=

60)

9.

Oil

pump driving

gear

(Z

=30)

10.

Idler gear

(Z

=58)

11.

Crankshaft belt wheel

, Crankshaft pulley is consisted

of

two

A - type V - belt

to

drive

water

pump

pulley

and

alternator pulley. Dfferent

of

V - belts are used because

of

the different position

of

water

pump

and alternator. V- belt is tensioned by alternator adjustment mecha-

nism.

When

press

the

center

of

V - belt by finger,

10

-15mm

depth should

be

availa-

ble.

Crankshaft timing gear drives idling gear,idling gear drives camshaft timing gear,fuel

injection

pump

timing gear and oil

pump

gear. Camshaft

timing

gear may drve air

compressor gear

of

work

pump

gear and bydraulic

pump

gear if necessary. Hydraulic

pump

gear may drive

the

front

and the rear hydraulic pump through

the

transmission

splined

hobs

of

hydaulc

upmp

or

one

of

them.

7. Intake and exhaust

system

7. 1 Air filter

When

the

diesel

engine

is working,clean and fresh air is required

to

be supplied by

the

air

filter,

this can assure

to

reduce

the

wear

of

cylinder liner,piston t piston rings,

valve and other parts.

For

the

air filter equipped

with

R series diesel engine, besides

one

or

two

types are

equipped by

OEM,

the

common

two

structure styles

are

as

follows

single stage

pa-

per filter element style ang double stages paper filter elemenl style

7. 2 Silencer

In order

to

reduce

the

noise and improve

the

operator's

working

environment,R

se-

ries diesel engine adopts exhaust silencer. The exhaust gas

of

the

diesel engine ex-

pands through

the

holes

of

the

silencer inner pipes and

the

noise is reduced.

If

the

• 33 •

Loading...

Loading...