2012 series Tooling (HK969) Alcoa Fastening Systems

13

Equipment Required:

• Shop airline with 90 - 100 psi max.

• Air regulator

• Fill Bottle 120337 (supplied with tool).

• Large flat blade screwdriver

• Nose assembly or optional Stall Nut

• Fasteners (optional)

• Optional Stall Nut, part no. 124090. (Stall nut is

used to load tool during bleeding and for meas-

uring stroke.)

Preparation:

1. Install air regulator in

air line and set pres-

sure to 20-40 psi.

2. Fill bleed bottle

almost full of

DEXRON III ATF

(automatic transmis-

sion fluid). Figure 4

.

Procedure to Fill Empty Tool (new or

rebuilt):

1. Attach the tool air source momentarily to seat air

piston at bottom of cylinder and disconnect tool.

With fill port facing up, lay tool on its side.

2. With a screwdriver, remove bleed plug from fill

port.

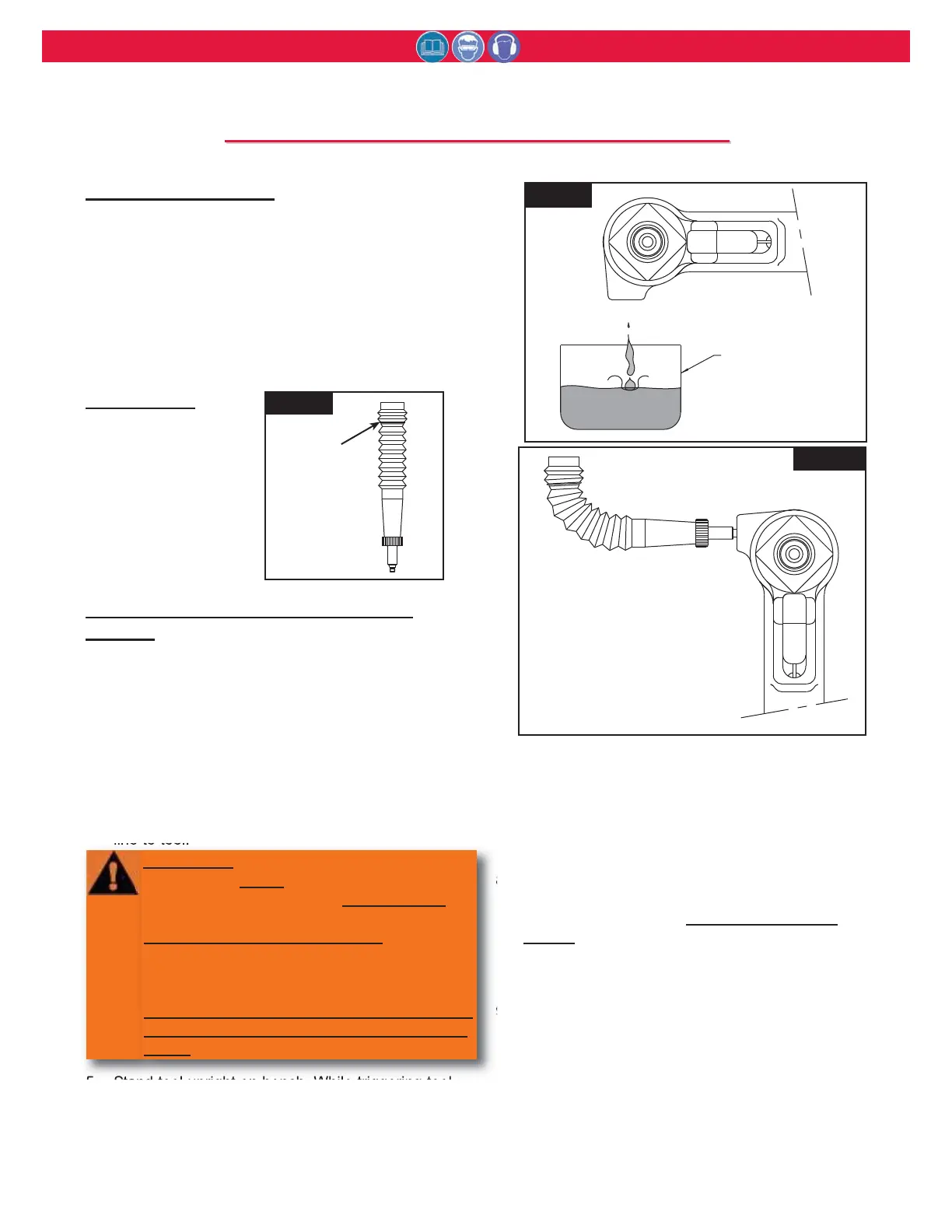

3. Screw fill bottle into fill port in the head.

4. Set air line pressure to 20-40 psi and connect air

line to tool.

5. Stand tool upright on bench. While triggering tool

slowly (20-30 cycles), bend fill bottle at right

angles to tool. Figure 4.2. Air bubbles will

emerge from tool. When bubbles stop, cycling

may be discontinued.

6. When trigger is released, pull piston returns to

idle position (full forward). Disconnect tool from

air line.

7. Lay tool on its side. Remove fill bottle. Top off

fluid in fill port. Install bleed plug and tighten.

8. Connect air line to tool. There is a choice of two

procedures for measuring the stroke: with and

without a stall nut. See S

EE HOW TO MEASURE

STROKE section and follow the selected proce-

dure. If stroke is less than specified, remove

bleed plug and top off fluid. Reinstall bleed plug.

9. Increase air pressure to specification. Install two

fasteners to check function and installation in a

single stroke, or cycle tool with stall-nut fully

threaded onto piston to load up tool. Measure

stroke again. Remove plug and top off fluid.

Reinstall plug and cycle again. Measure again.

Continue this process until stroke meets mini-

mum requirements.

continued

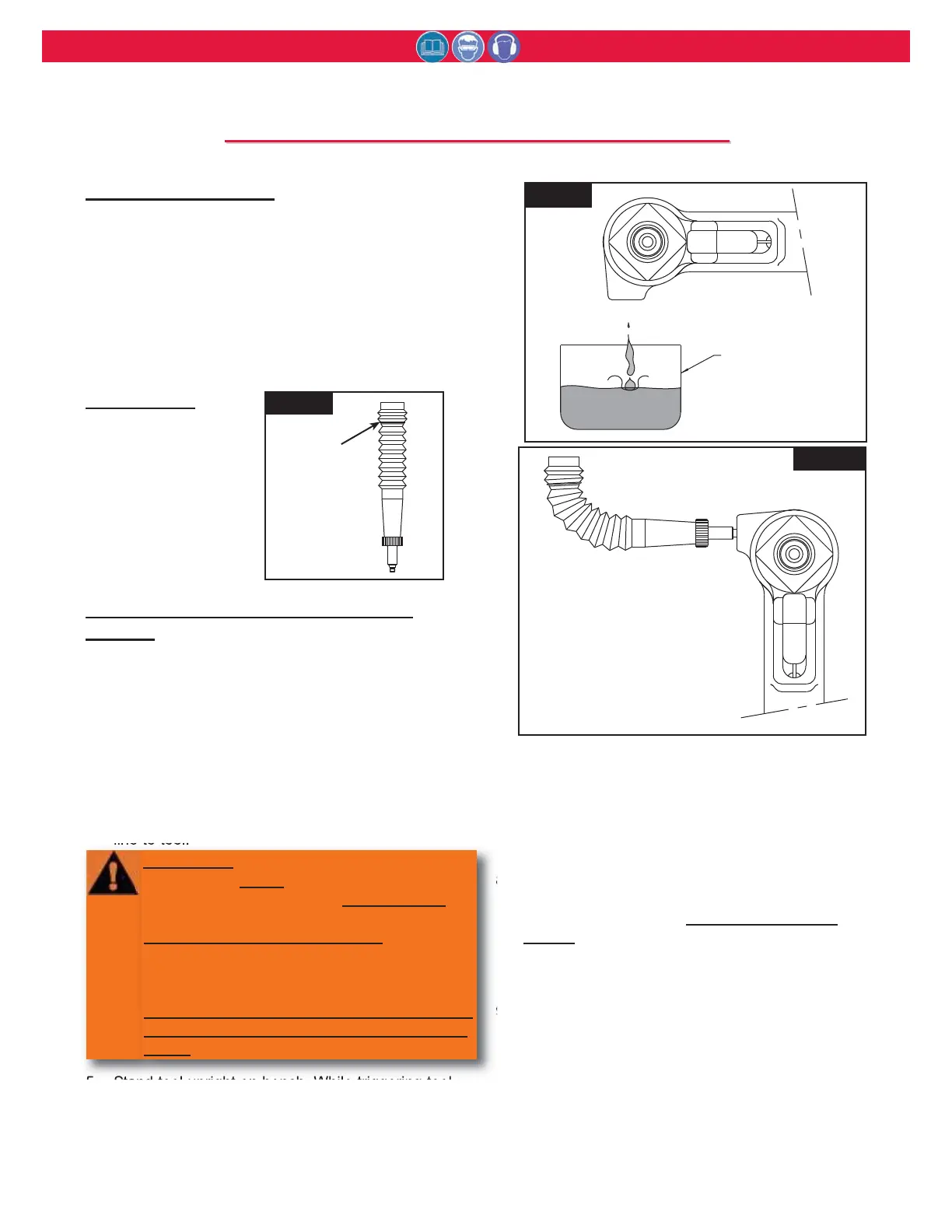

Fig. 4

Fig. 4.1

Fig. 4.2

WARNING

Air pressure MUST be set to 20-40 psi to

prevent possible injurious high pressure

spray.

NEVER CYCLE TOOL WITHOUT:

BLEED PLUG TIGHTENED

FILL BOTTLE TIGHTENED IN TOOL, or

FILLPORT HELD OVER A RECEPTACLE Figure 4.1

When not properly contained any fluid pres-

ent in tool will spray out. Severe injury may

result.

F

F

ILLING

ILLING

AND

AND

B

B

LEEDING

LEEDING

P

P

ROCEDURE

ROCEDURE

Loading...

Loading...