9

3585 Series Hydraulic Installation Tools (HK1080) Howmet Fastening Systems

OPERATING INSTRUCTIONS

Read all of these instructions in order to ensure the safe operation of this equipment.

This section details installing HuckBolt

®

Fasteners.

these fasteners. If the tool malfunctions, consult

TROUBLESHOOTING prior to attempting any repairs.

NOTE: Reasonable care of tools by operators is an

downtime.

Prior to starting these procedures, check the tool’s

proper orientation of the

tool.

To install a HuckBolt Fastener:

1. Place a fastener in the workpiece and place the

collar over the fastener.

NOTE: The beveled end of the collar must be

towards the nose assembly and tool.

2. Hold the fastener and push the nose assembly onto

the fastener that is protruding through the collar until

the nose anvil touches the collar.

NOTE: The tool and nose assembly must be at right

angles (90°) to the work.

3. Press and hold the trigger to start installation cycle.

4. Release the trigger when forward motion of nose

assembly anvil stops and pintail breaks off.

The pressure is re-directed; the piston moves forward;

and the tool is pushed off the fastener and ejects the

pintail. The tool and nose assembly are ready for the

next installation cycle.

CAUTION: Remove excess gap from

between the sheets to permit proper

fastener installation and prevent jaw

damage. ALL jaw teeth must engage the

pintail to avoid damaging the teeth.

WARNING:

• Wear approved eye and hearing

protection.

• Ensure there is adequate clearance for

operator’s hands before proceeding with

fastener installation.

•

to the tool and directed away from all

personnel.

• Do not pull on a pin without placing a

fastener in a workpiece. Make sure that

the collar chamfer is out, toward the

tool. Pins eject with great velocity when

pintails break off or teeth/grooves strip,

which could cause severe injury.

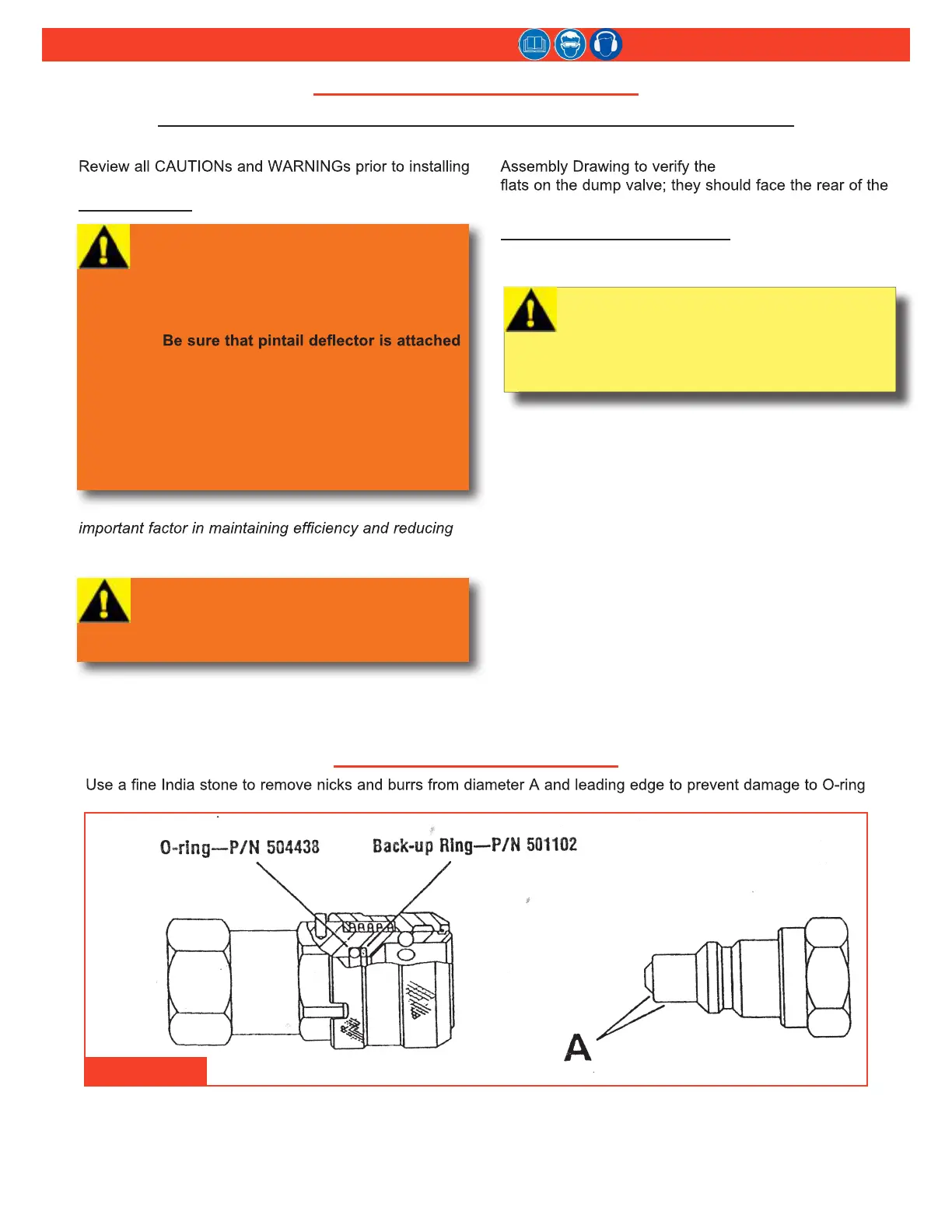

HYDRAULIC COUPLINGS

FIGURE 2

.

WARNING: Make sure the tool has been

properly re-assembled prior to use. Failure

to do so could result in serious personal

injury.

Loading...

Loading...