WHEELS & BRAKES

28

10

10 C

REAR BRAKE:

The Husaberg motorcycle is equipped with a

Brembo hydraulic disc brake. For your own safety

it needs to be frequently serviced and checked.

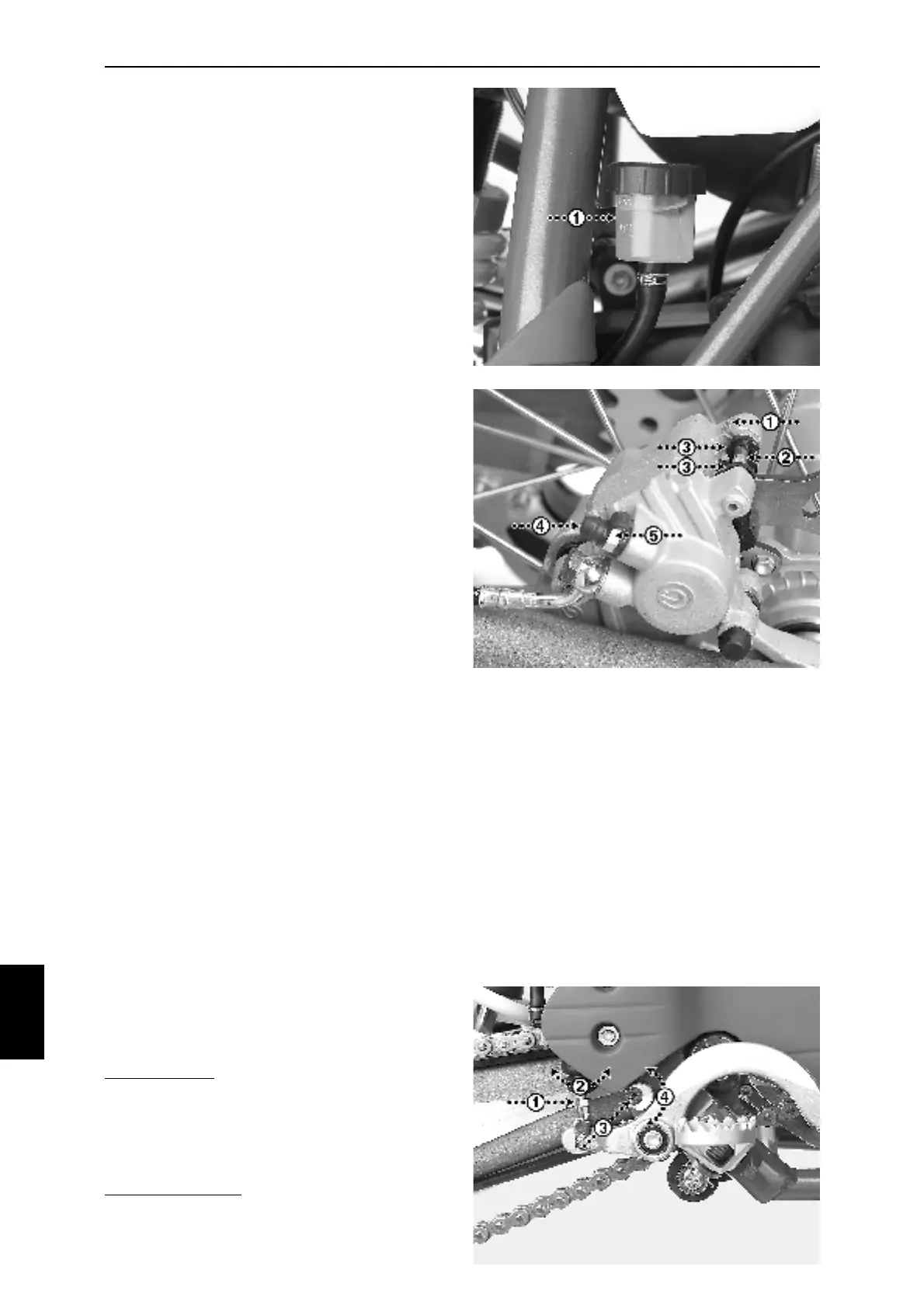

Always check the level of brake fluid in the

reservoir (Fig. 10P-1). The level has to be within

the MIN and MAX marks when the motorcycle is

upright.

Always check the brake hoses for any leakage

and/or deterioration.

Always check the wear of the brake pads. Change

the pads if the total thickness of each pad is less

than 1,5 mm, excluding the metal part.

Brake fluid:

Add fluid; DOT 4, by removing the cap on the

reservoir and the gasket. Take care - the fluid is

toxic and could also harm the surfaces of the

motorcycle.

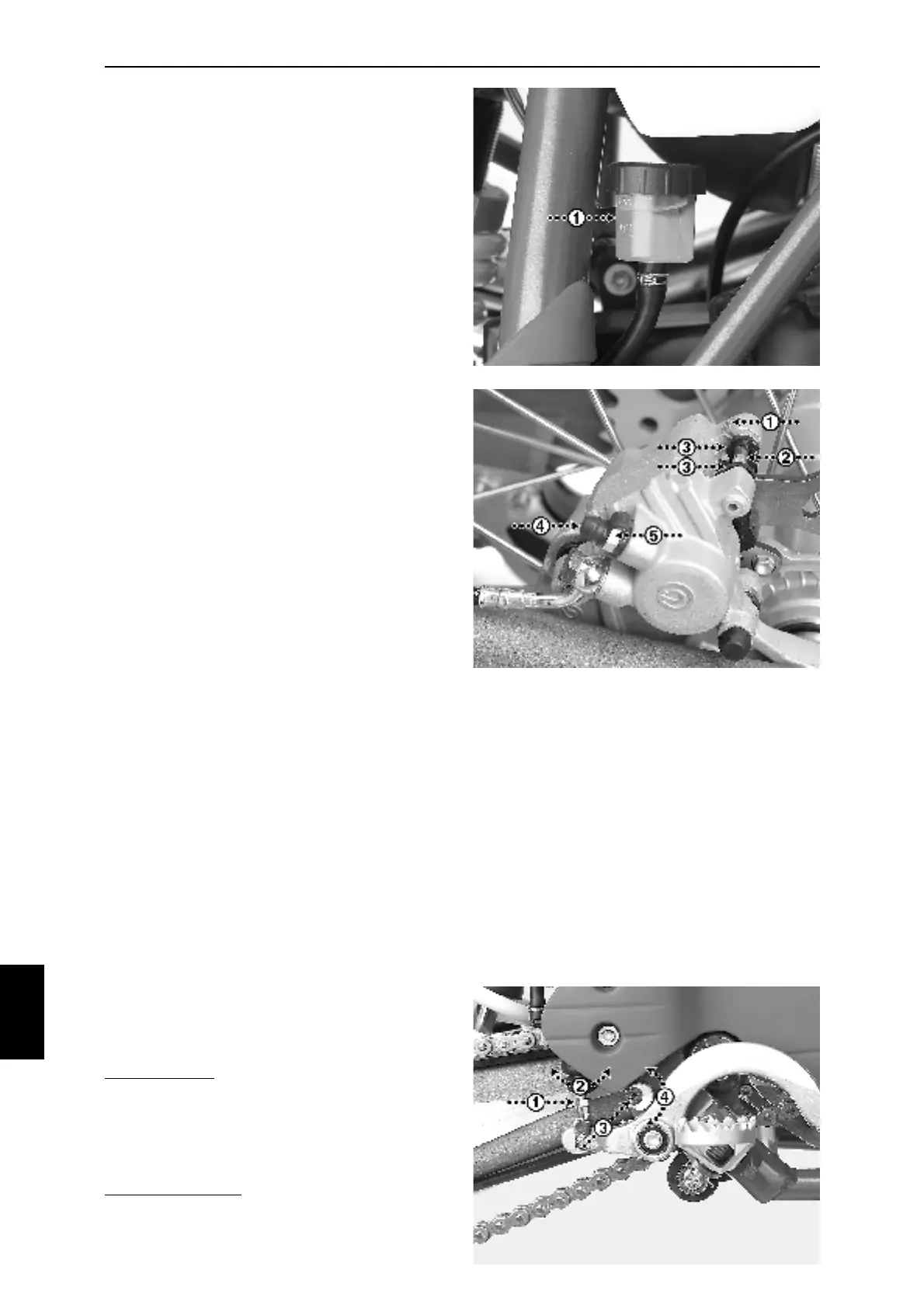

Brake pads:

Remove the clip (Fig. 10Q-1) holding the brake

pad pin (Fig. 10Q-2).

Remove the two brake pads by removing the pin

and pulling the two pads out (Fig. 10Q-3).

Fit new pads in reverse order.

Air bleeding:

Remove the dust cap (Fig. 10Q-4) and ensure

that the air nipple (Fig. 10Q-5, wrench No.11) is

easily opened. With the nipple in closed position;

push the lever downwards a couple of times and

keep it under pressure the last time. Open the

nipple slightly and the brake lever, still under

pressure, will move downwards allowing any air,

and fluid, to run through the brakeline and nipple.

Before releasing the pressure onto the lever; close

the air nipple.

Repeat the steps until no more air is visible. Make

sure that the reservoir has enough fluid all the

time.

Fig.

10P

Fig.

10Q

Fig.

10R

Adjustment of brake lever:

The rear brake lever is easily adjusted into a

personal point of pressure and height of the lever.

Pressure point: release the lock nut (Fig. 10R-1,

wrench No.10) of the pushrod and turn the

pushrod into selected position (Fig. 10R-2).

Always keep a clearance in between the lever and

the point of pressure. Tighten the locknut.

Height of the lever: release the allen screw (Fig.

10R-3, allen key No. 4) and turn the eccentric

adjustment (Fig. 10R-4) into selected position.

Tighten the allen screw.

Loading...

Loading...