Do you have a question about the Husqvarna 225L and is the answer not in the manual?

Essential gear like gloves, ear/eye protection, boots, and clothing for safe operation.

Details on throttle lock, stop switch, and cutting guards for operational safety.

Describes the system reducing vibrations for user comfort and its maintenance checks.

Muffler function, spark arrest screen, and warnings about hot surfaces and fumes.

Focuses on the trimmer head and its intended use for grass trimming.

Explains the function of the locking nut securing cutting equipment and its maintenance.

Guide on how to check, maintain, and service the machine's safety features for optimal performance.

Guidance on correct maintenance and selection of cutting equipment for capacity and service life.

Instructions for winding trimmer cord tightly and evenly to avoid vibrations and ensure proper function.

Details on safely assembling and tightening the locking nut for cutting equipment.

Basic precautions for safe operation, including usage limitations and environmental awareness.

Guidelines for safe refueling, fuel storage, and handling, emphasizing fire and fume risks.

Instructions for safe transport and storage of the machine and fuel, preventing leaks and hazards.

Key safety precautions for working with the trimmer, including observing surroundings and avoiding hazards.

Essential steps to ensure safety while operating the trimmer, such as checking surroundings and footing.

Procedures for effective trimming, including throttle use and stopping the engine for cleaning.

Techniques for grass trimming, focusing on head angle, cord use, and avoiding damage to surroundings.

Method for removing unwanted vegetation using the trimmer head, including tilt and cord wear.

How to trim grass effectively, keeping the cord parallel and avoiding ground contact.

Using the trimmer's fanning effect for quick cleaning of debris.

Step-by-step instructions for attaching the loop handlebar and adjusting for comfortable use.

Procedure for connecting and separating the two-part shaft assembly for the 225LD model.

Guide for fitting the spray guard and Superauto II trimmer head to the cutting attachment.

Instructions for attaching additional guards and cutting equipment to the trimmer.

Details on the correct petrol and two-stroke oil mixture ratio and best practices for mixing.

Safety measures for refueling the machine, emphasizing fire prevention and ventilation.

Essential checks to perform before starting the engine to ensure safety and proper function.

Step-by-step guide for starting the engine, including choke and throttle usage.

Simple instructions on how to safely stop the engine using the stop switch.

Explanation of carburetor function, adjustment points (L, H, T) and basic settings.

Procedure for adjusting the low-speed needle for optimal idling and acceleration.

How to adjust the idling speed screw (T) to ensure the cutting attachment stops at idle.

Procedure for adjusting the high-speed needle for optimal engine performance and preventing damage.

Indicators of a correctly adjusted carburetor, including acceleration and idling behavior.

Instructions for cleaning and checking the muffler, including spark arrest screen and catalytic converter.

How to clean the cooling system (air intake, fins, cover) to prevent engine overheating.

Steps for cleaning the air filter to maintain engine performance and prevent issues.

Guidance on checking electrode gap, cleaning, and replacing the spark plug for optimal engine function.

Information on checking and lubricating the angle gear with HUSQVARNA special grease.

Instructions for lubricating the drive axle ends on two-part shafts to prevent jamming.

Overview of daily, weekly, and monthly maintenance tasks for the machine.

Detailed technical data for the engine, including capacity, bore, stroke, and speeds.

Measured noise and vibration levels for the machine under various operating conditions.

List of recommended accessories, types, and associated part numbers.

Explanation of owner's responsibilities for maintenance and warranty claims.

Details on the duration and scope of the manufacturer's warranty for emission-related parts.

Information on how to obtain warranty service and file a claim.

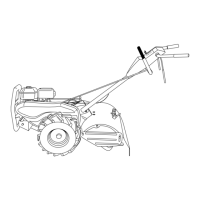

This document is an operator's manual for Husqvarna 225L/LD, 225L Lite, and 232L trimmers. It provides detailed information on the machine's function, safety, assembly, fuel handling, starting and stopping procedures, maintenance, and technical data.

The Husqvarna 225L/LD, 225L Lite, and 232L are trimmers designed primarily for trimming grass and clearing unwanted vegetation. The engine unit acts as the drive source for various cutting attachments. The machine is equipped with a vibration damping system to reduce the transfer of vibrations between the engine unit/cutting equipment and the handles, aiming for comfortable use. A muffler is integrated to minimize noise and direct exhaust fumes away from the operator; some models feature a catalytic converter to reduce harmful exhaust components and a spark arrest screen to mitigate fire risk. The cutting equipment, typically a trimmer head with a cord, is secured by a locking nut on the output shaft. The throttle trigger lock prevents accidental engagement of the throttle, and a stop switch is provided for immediate engine shutdown.

| Brand | Husqvarna |

|---|---|

| Model | 225L |

| Category | Lawn and Garden Equipment |

| Language | English |