REV B 4-12 117364

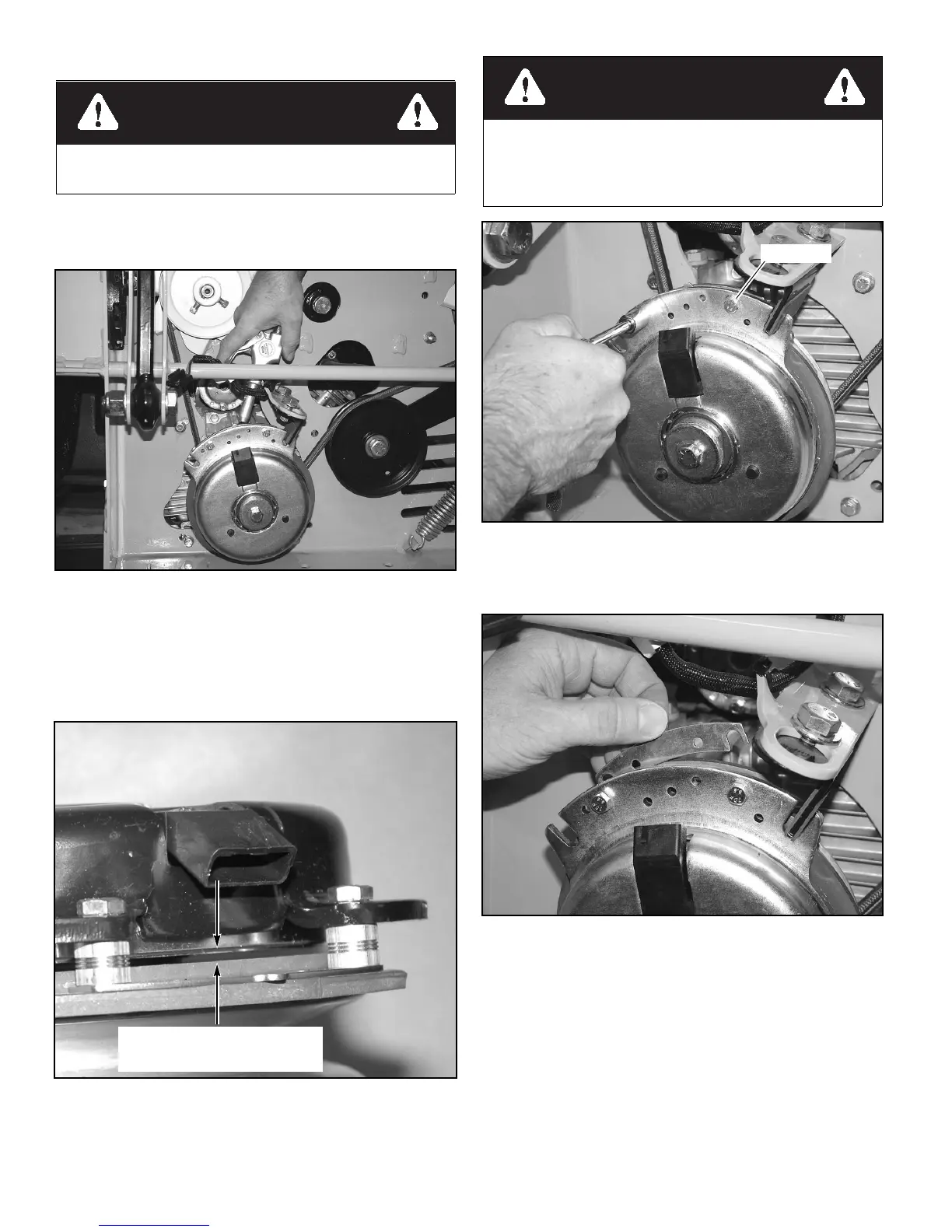

Procedure:

With engine off, key removed and clutch disengaged and

using a pneumatic line, blow out any debris from under the

brake pole and around the aluminum spacers. Figure 4-31

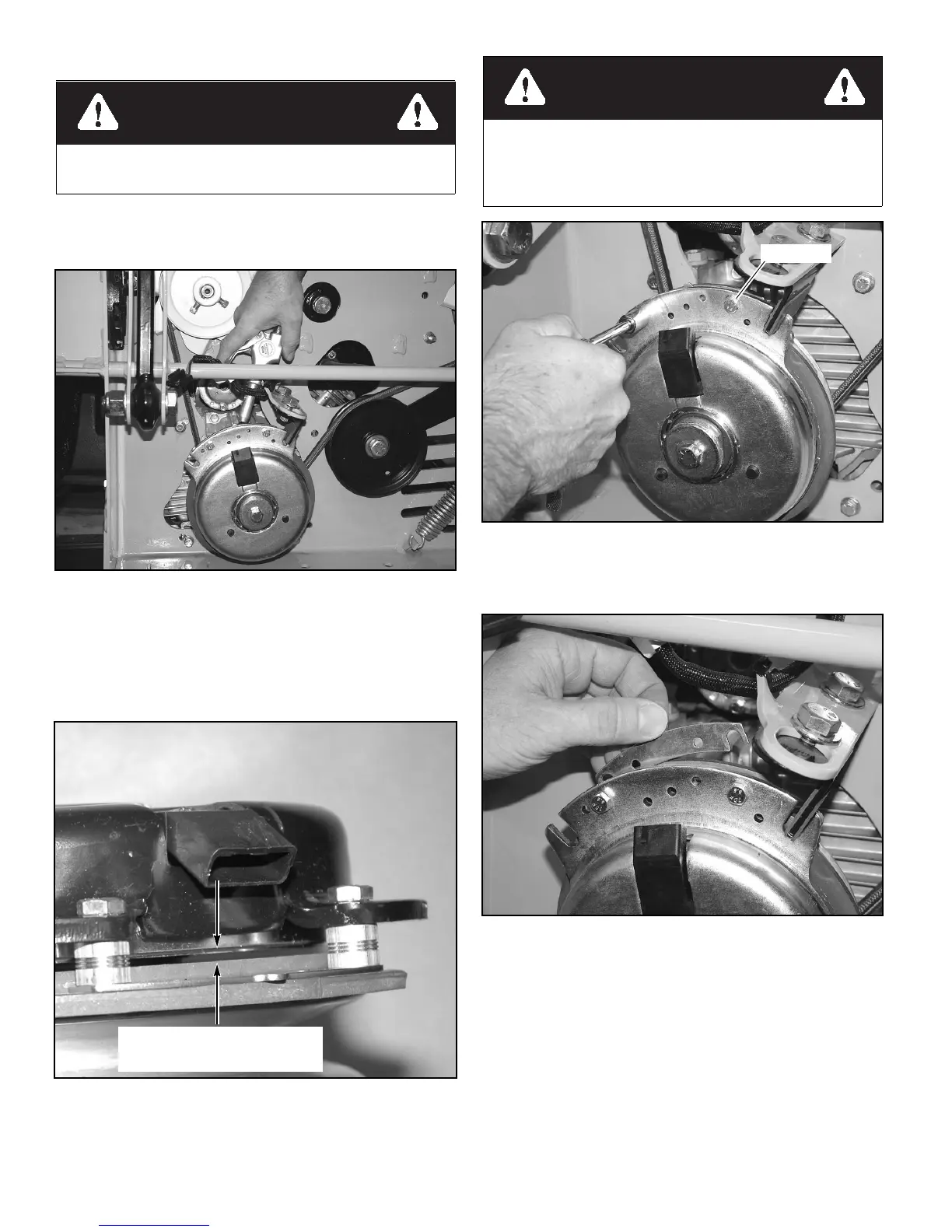

Check the air gap between rotor & armature with feeler gage.

If the gap is less than .070”, then follow the troubleshooting

procedure outlined in Warner Electric P1177 installation

troubleshooting guide available on Warner Electric’s web site-

www.Warnerelectric.com. If the air gap is over .070”, follow the

procedure outlined below. Figure 4-32

1. Loosen both brake mounting bolts 1/2 to 1 full turn as

shown in Figure 4-33.

2. Using needle nose pliers, or by hand, take hold of the tab

and remove shim (do not discard shim until proper clutch

function has been confirmed). Figure 4-34

3. Using a pneumatic line, blow out any debris from under

the brake pole and around the aluminum spacers. Figure

4-31

4. Re-torque each bolt (M6 X 1) to 120 in.-lbs.

5. Using a .015” thick feeler gage, verify that a gap is

present between the rotor and armature face on both ends

of the brake pole as shown. Figure 4-35 and Figure 4-36

a. If the gap is less than .015” the clutch must be

replaced

b. If sufficient gap is present, then proceed to safety

check outlined below.

Always wear adequate eye protection when servicing the

mower.

Figure 4-31

Figure 4-32

Be certain that the gap between the

rotor and armature face is greater

than .070” prior to shim removal.

Do not remove brake pole from field shell/armature. The

brake pole tracks match with the clutch brake and need to

continue to match after shim is removed to ensure proper

brake torque. Figure 4-30

Figure 4-33

Figure 4-34

Loading...

Loading...