117364 6-5 REV B

Belts

Inspect belts frequently for wear and serviceability. Replace a

belt that shows signs of severe cuts, tears, separation, weather

checking and cracking, or burns caused by slipping. Slight

raveling of belt covering does not indicate failure; trim ravelings

with a sharp knife.

Inspect the belt pulley grooves and flanges for wear. A new

belt, or one in good condition, should never run against the

bottom of the groove. Replace the pulley when this is the case,

otherwise, the belt will lose power and slip excessively.

Never pry a belt to get it on a pulley as this will cut or damage

the fibers of the belt covering.

Keep oil and grease away from belts, and never use belt

dressings. Any of these will destroy the belt composition in a

very short time.

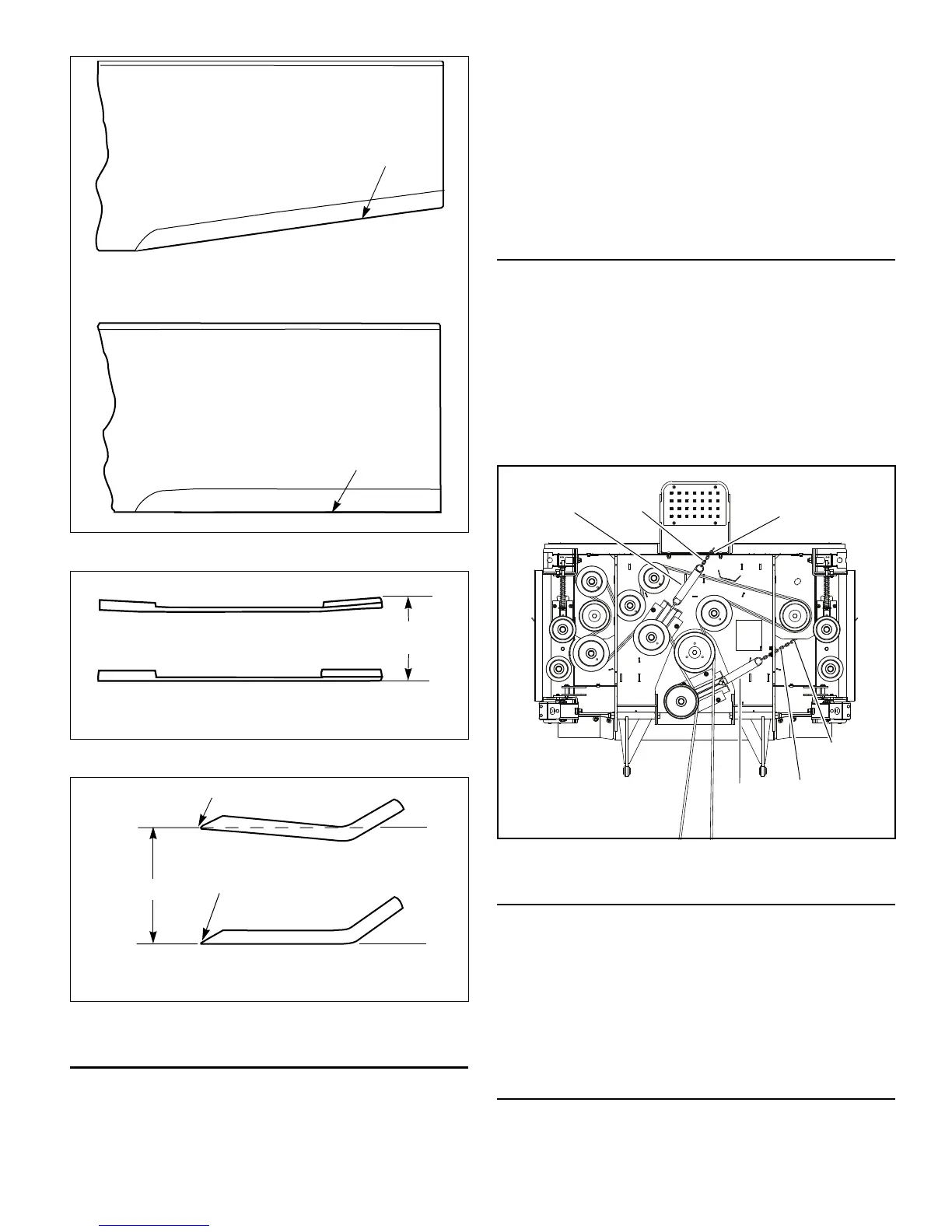

Center Deck Belts Adjustment

The deck belt tension remains constant by means of a tension

idler and spring. The spring tension should be such that the belt

does not slip under normal operating load conditions, assuming

the belt is not excessively worn or damaged. As the belt

stretches and wears in, adjustment may become necessary. To

increase belt tension, move the spring chain one (or more)

link(s) at the anchor point on the deck frame. Figure 6-14,

Figure 6-15 & Figure 6-16

IMPORTANT: Do not over tension the spring to compensate

for a badly worn belt or pulley.

Side Deck Belt Adjustment

The side deck belt tension is adjusted by changing the

compressed length of the idler spring.

1. Loosen the jam nut. Figure 6-16

2. Rotate the adjustment nut the proper the direction until

the idler spring is compressed to the dimension shown.

Figure 6-16

3. Tighten the jam nut against the adjustment nut. Figure 6-

16

Deck Troubleshooting

If you are experiencing issues with cut quality, deck

discharge, or deck functionality refer to the Troubleshooting

section of this manual.

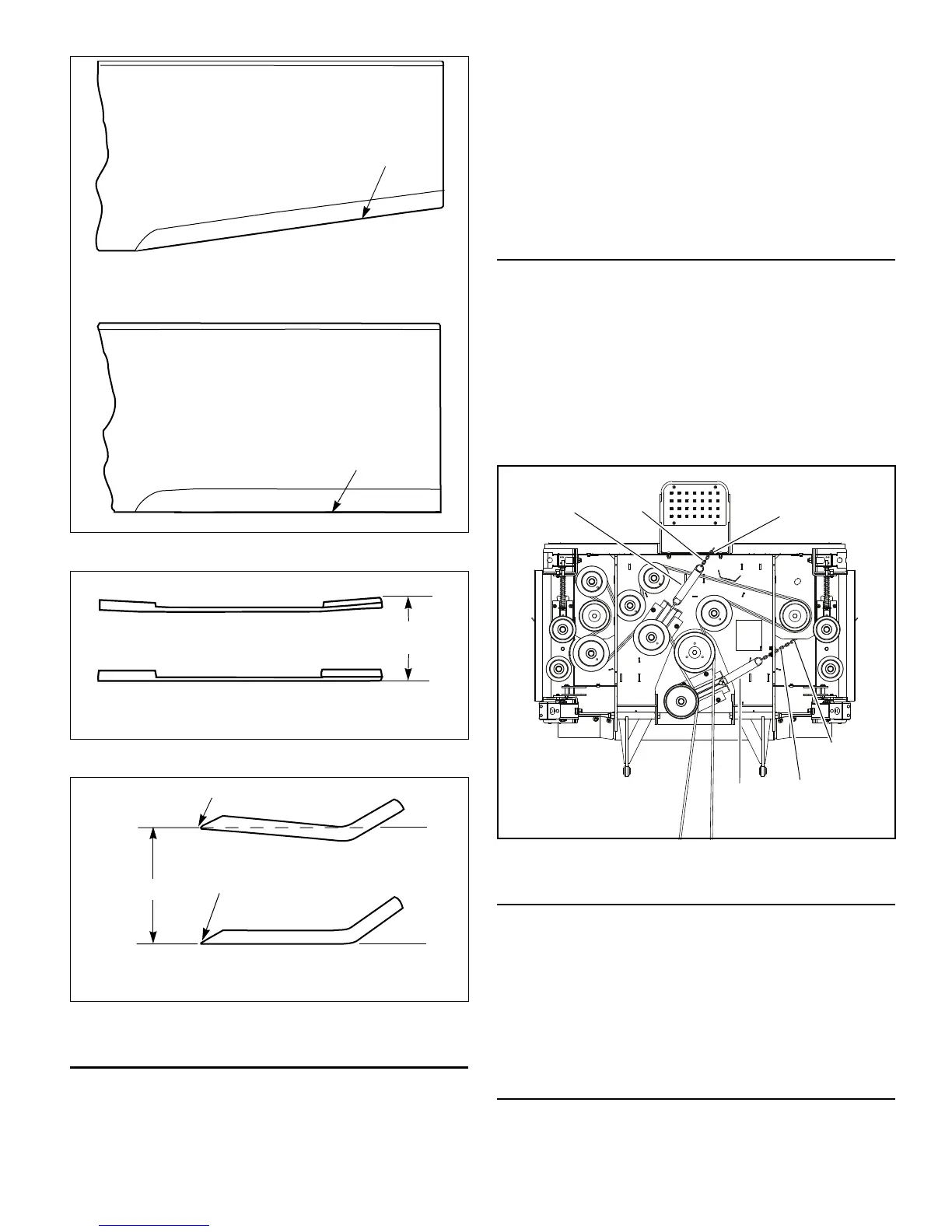

Figure 6-11

Figure 6-12

Figure 6-13

Resharpening

pattern

Do not sharpen to original pattern (below). It is

easier to get a straight cutting edge following

the resharpening pattern shown above.

Original edge

Warped Blade (Replace)

Straight Blade

Cutting

plane

Comparison of Warped and Straight Blades

Cutting edge

Twisted Blade Edge

(replace)

Cutting edgeCutting Plane

Straight Blade Edge

End view of blades, comparing

twisted and straightened blades

Figure 6-14

Spring

chain

Spring chain

anchor point

Idler

spring

Spring

chain

Spring chain

anchor point

Idler

spring

Loading...

Loading...