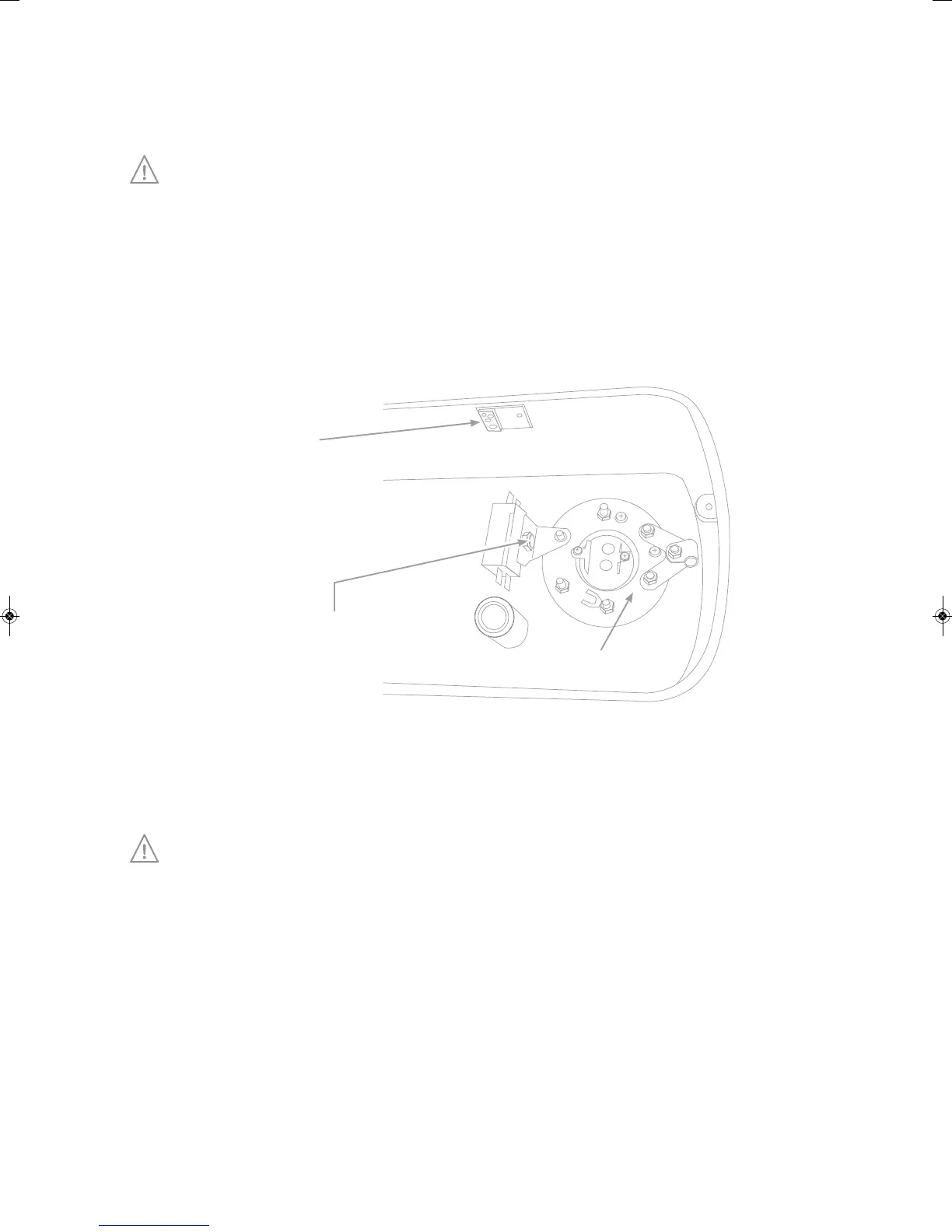

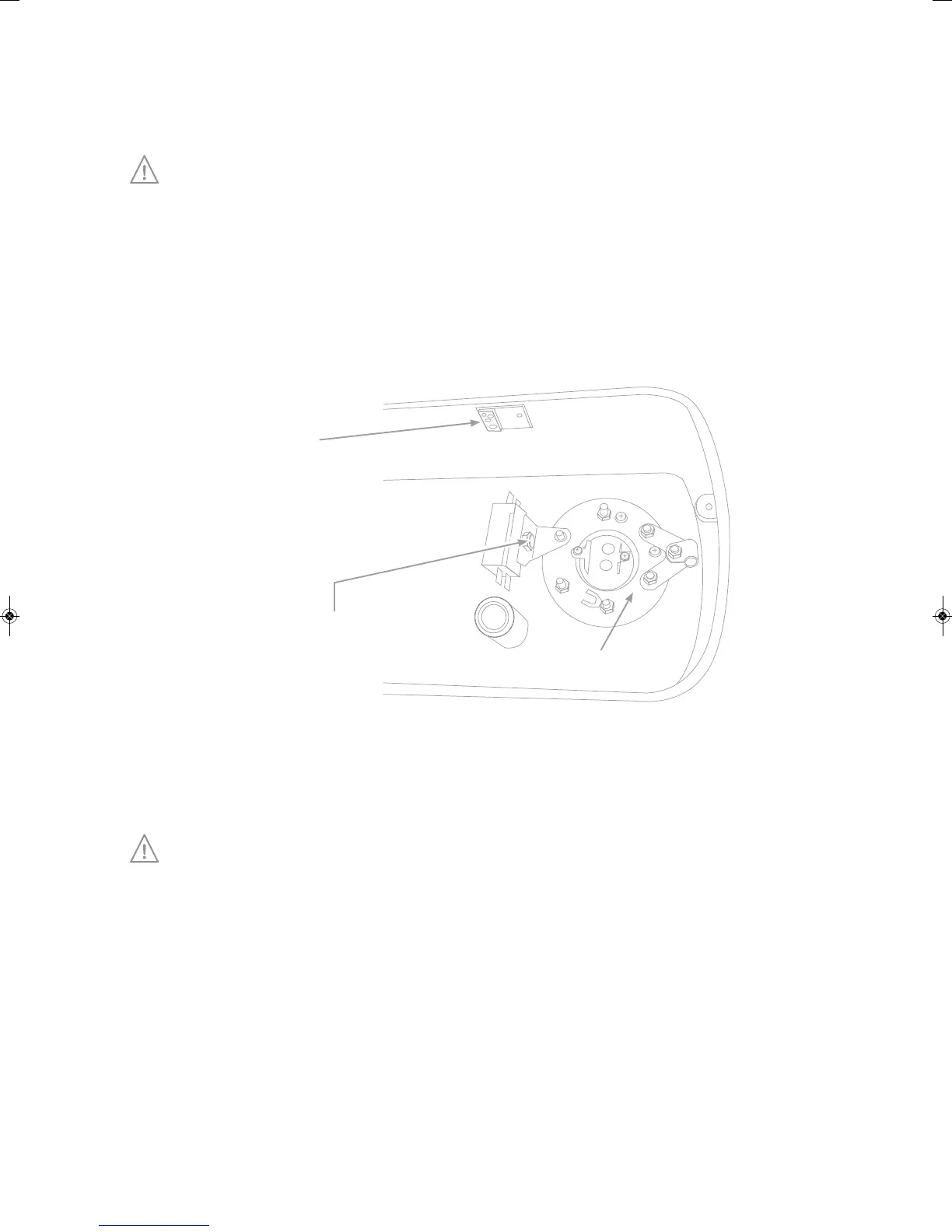

All maintainable electrical components are located under a plastic cover that is next to the inlet and outlet

pipes and held in position with two small screws. Remove screws and lower cover to provide access to

components. See diagram below for electrical parts identification.

If replacing electrical parts take particular attention to ensure that the earthing connections

(green/yellow) to the element flange and thermostat housing are sound.

Thermal cut-out reset

This unit contains a manually re-settable thermal cut-out that will switch the power off if the temperature

reaches an abnormally high level. To reset the cut-out the press button as shown in Diagram 4.

De-scaling procedure

If scale is allowed to build up heater performance will suffer and the life of the product will be reduced.

The effects of limescale are excluded from any warranty.

To de-scale the heater, gain access to the element following the instructions set out in section 10.

•

Remove thermostat and thermal cut-out bulbs from respective pockets and unscrew the 6 nuts holding

the element flange in position. Withdraw element.

•

Remove scale carefully. If necessary, dip element in a de-scaling solution available from DIY or plumbing

outlets. Do not allow electrical connections to become wet.

•

It is not normally necessary (or practical) to attempt to remove any scale from the tank walls.

•

Refit element and follow commissioning instructions as per section 8.

Temperature and

Pressure Relief Valve

POWERFLOW

Hot

Drain Cock

To Drain (Waste)

Pressure

(Expansion)

Relief Valve

Expansion

Vessel

Check

Valve

Balanced

Cold W ater

Draw O

Pressure

Reducing V alve

Service

Valve

Cold W ater

Mains

Diagram 1

B

A

Diagram 2

Model

Vertical

Bolt

Spacing A (mm)

Horizontal Bolt

Spacing B (mm)

PF30L 270320

PF50L 52

0320

PF90L 430320

Safety Device

Tundish

600mm MAXIMUM

Metal Discharge Pipe (D1) from

Temperature Relief to Tundish

Discharge Below

Fixed Grating

300mm MINIMUM

Metal Discharge Pipe (D2) from

Tundish with Continuous Fall

Fixed Grating

Trapped Gully

Sizing of D2 Copper Discharge pipe for common temperature relief valve outlet size

Valve

outlet

size

Minimum size of

discharge pipe (D1)

Minimum size of

discharge pipe (D2)

from Tun di s h

Maximum resistance allowed,

expressed as a length of straight

pipe (I.E. no elbows or bends)

Resistance

created by each

elbow or bend

m8.0m9otpumm22mm512/1G

28mm up to 18m 1.0m

m4.1m72ot*mm53

Diagram 4

Element ange -

Remove to access anode

Thermostat

Thermal cutout -

Press here to reset

H

Diagram 3

WD

Loading...

Loading...