Plan your installation carefully and choose a suitable position for the heater, allowing suitable space for

accessories such expansion vessels, pipework and subsequent maintenance.

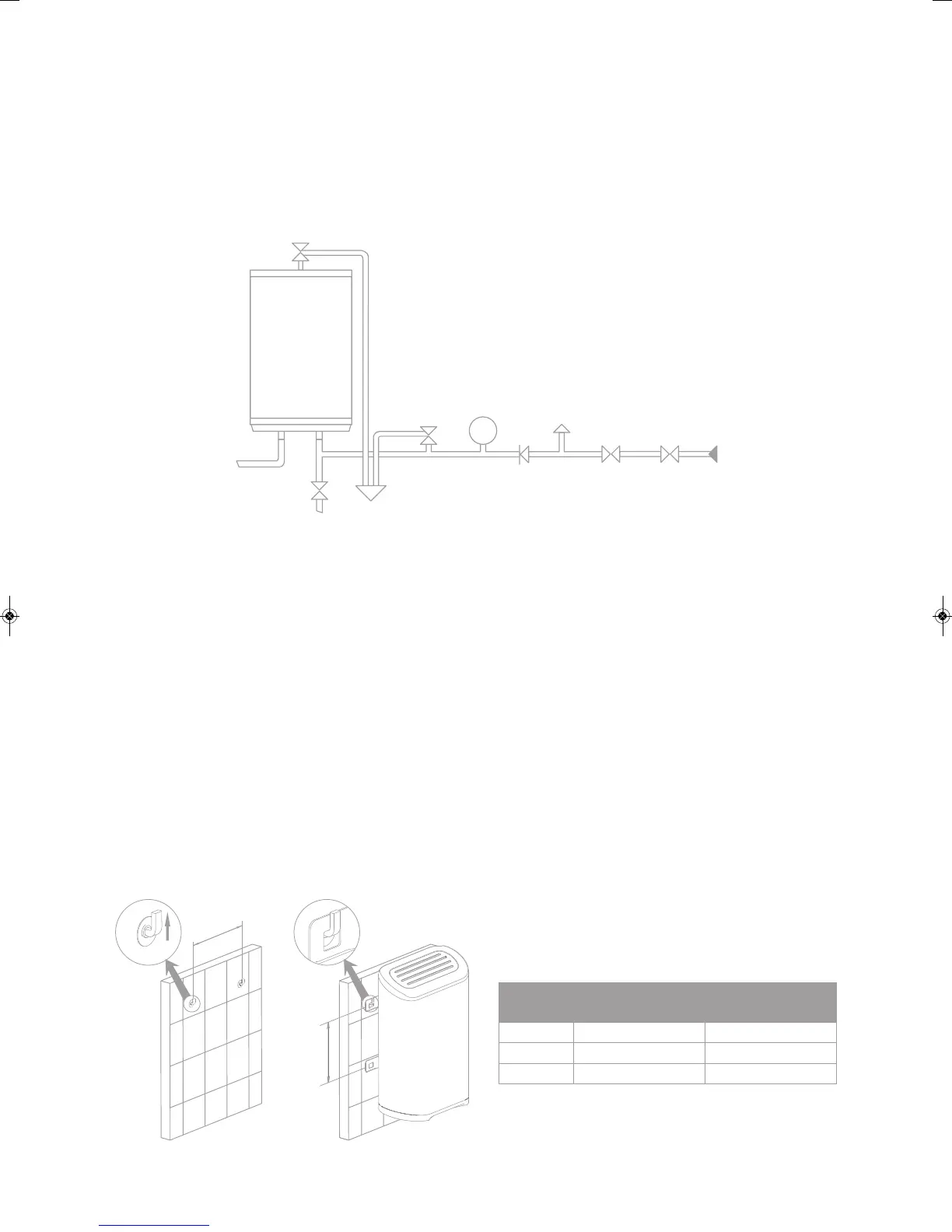

See schematic Diagram 1 for the correct relative positions of the components.

•

Fit all the components supplied, components may be supplied loose or connected to a mainfold.

The manifold aids installation but does not alter the relative positions of the components.

•

Do not remove the factory fitted temperature and pressure relief valve.

•

Ensure in particular that there are no valves of any kind between the expansion relief vlave and the heater.

•

Allow at least 400mm of space above and below the unity to permit for maintenance.

•

Observe flow direction arrows on components.

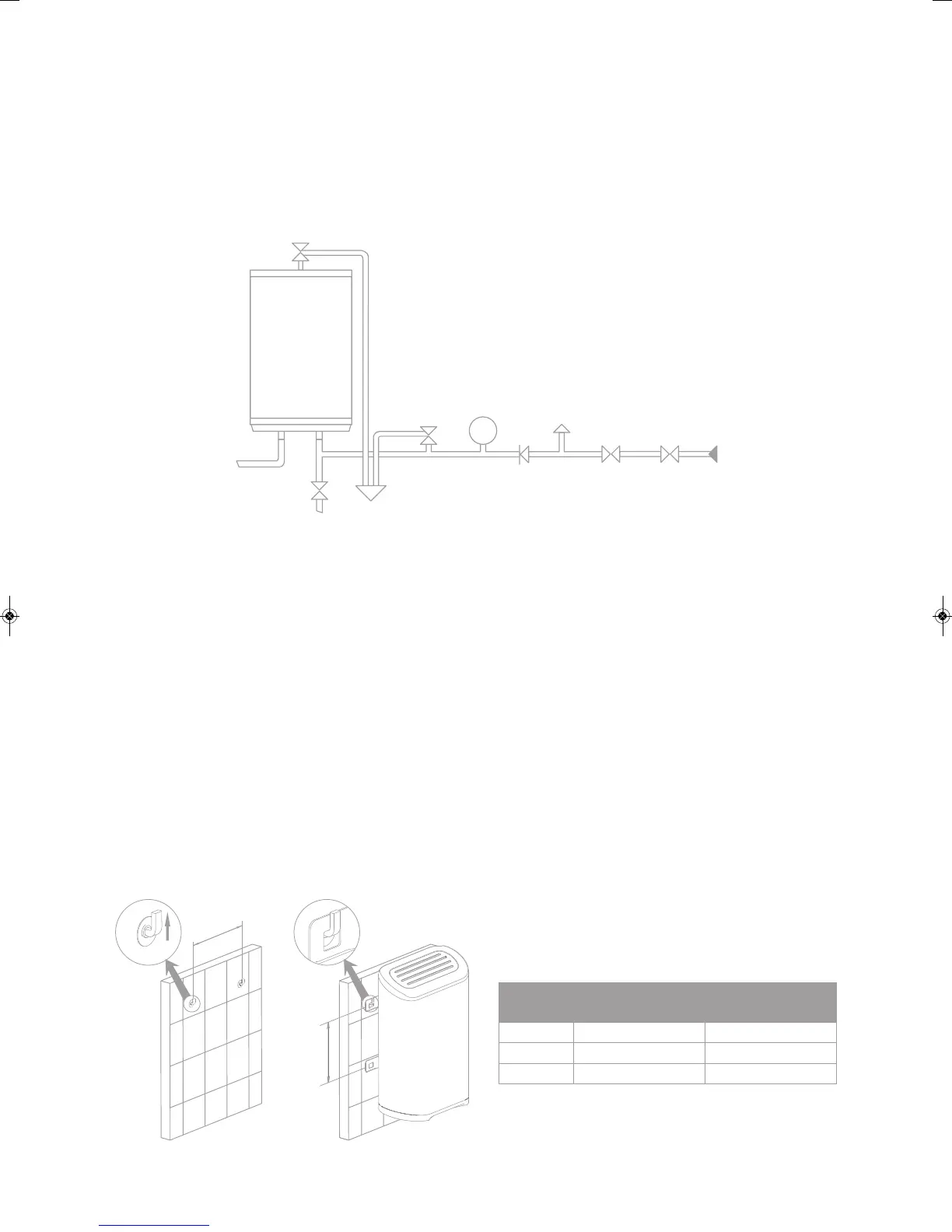

Wall mounting

Drill holes for supplied heavy duty bolts to wall at the spacings shown in the table below (also See Diagram 2).

Insert bolt hooks and tighten ensuring that they are secure then hang heater on the protruding hooks.

Temperature and

Pressure Relief Valve

POWERFLOW

Hot

Drain Cock

To Drain (Waste)

Pressure

(Expansion)

Relief Valve

Expansion

Ve ss el

Check

Valve

Balanced

Cold W ater

Draw O

Pressure

Reducing V alve

Service

Valve

Cold W ater

Mains

Diagram 1

B

A

Diagram 2

Model

Ve

rtical

Bolt

Spacing A (mm)

Horizontal Bolt

Spacing B (mm)

PF30L 270320

PF50L 52

0320

PF90L 430320

Safety Device

Tundish

600mm MAXIMUM

Metal Discharge Pipe (D1) from

Temperature Relief to Tundish

Discharge Below

Fixed Grating

300mm MINIMUM

Metal Discharge Pipe (D2) from

Tundish with Continuous Fall

Fixed Grating

Trapped Gully

Sizing of D2 Copper Discharge pipe for common temperature relief valve outlet size

Valve

outlet

size

Minimum size of

discharge pipe (D1)

Minimum size of

discharge pipe (D2)

from Tundish

Maximum resistance allowed,

expressed as a length of straight

pipe (I.E. no elbows or bends)

Resistance

created by each

elbow or bend

m8.0m9otpumm22mm512/1G

28mm up to 18m 1.0m

m4.1m72ot*mm53

Diagram 4

Element ange -

Remove to access anode

Thermostat

Thermal cutout -

Press here to reset

H

Diagram 3

WD

Temperature and

Pressure Relief Valve

POWERFLOW

Hot

Drain Cock

To Drain (Waste)

Pressure

(Expansion)

Relief Valve

Expansion

Ve ss el

Check

Valve

Balanced

Cold W ater

Draw O

Pressure

Reducing V alve

Service

Valve

Cold W ater

Mains

Diagram 1

B

A

Diagram 2

Model

Vertical Bolt

Spacing A (mm)

Horizontal Bolt

Spacing B (mm)

PF30LC

PF50LC

PF90LC

430320

Safety Device

Tundish

600mm MAXIMUM

Metal Discharge Pipe (D1) from

Temperature Relief to Tundish

Discharge Below

Fixed Grating

300mm MINIMUM

Metal Discharge Pipe (D2) from

Tundish with Continuous Fall

Fixed Grating

Trapped Gully

Sizing of D2 Copper Discharge pipe for common temperature relief valve outlet size

Valve

outlet

size

Minimum size of

discharge pipe (D1)

Minimum size of

discharge pipe (D2)

from Tundish

Maximum resistance allowed,

expressed as a length of straight

pipe (I.E. no elbows or bends)

Resistance

created by each

elbow or bend

m8.0m9otpumm22mm512/1G

28mm up to 18m 1.0m

m4.1m72ot*mm53

Diagram 4

Element ange -

Remove to access anode

Thermostat

Thermal cutout -

Press here to reset

H

Diagram 3

WD

Powerflow_Layout 1 28/06/2015 10:09 Page 3

Loading...

Loading...