16

D10-991-2400B

D/G-10 Service (Hydraulic End)

1. Remove Pump Housing

a. Remove head of pump, and diaphragms, as outlined in the

Fluid-End Service Section.

b. Drain oil from pump housing by removing drain plug (34).

c. Set hydraulic end of pump face- down on cylinder

housing (24), onto smooth, clean surface.

d. Check shaft for sharp burrs. Smooth any burrs, to prevent

scarring housing seals (64) when you disassemble pump.

e. Remove bolts (29; 25 or 44) that secure housing to cylinder

casting. Piston return springs (50) will force cylinder housing

and housing apart.

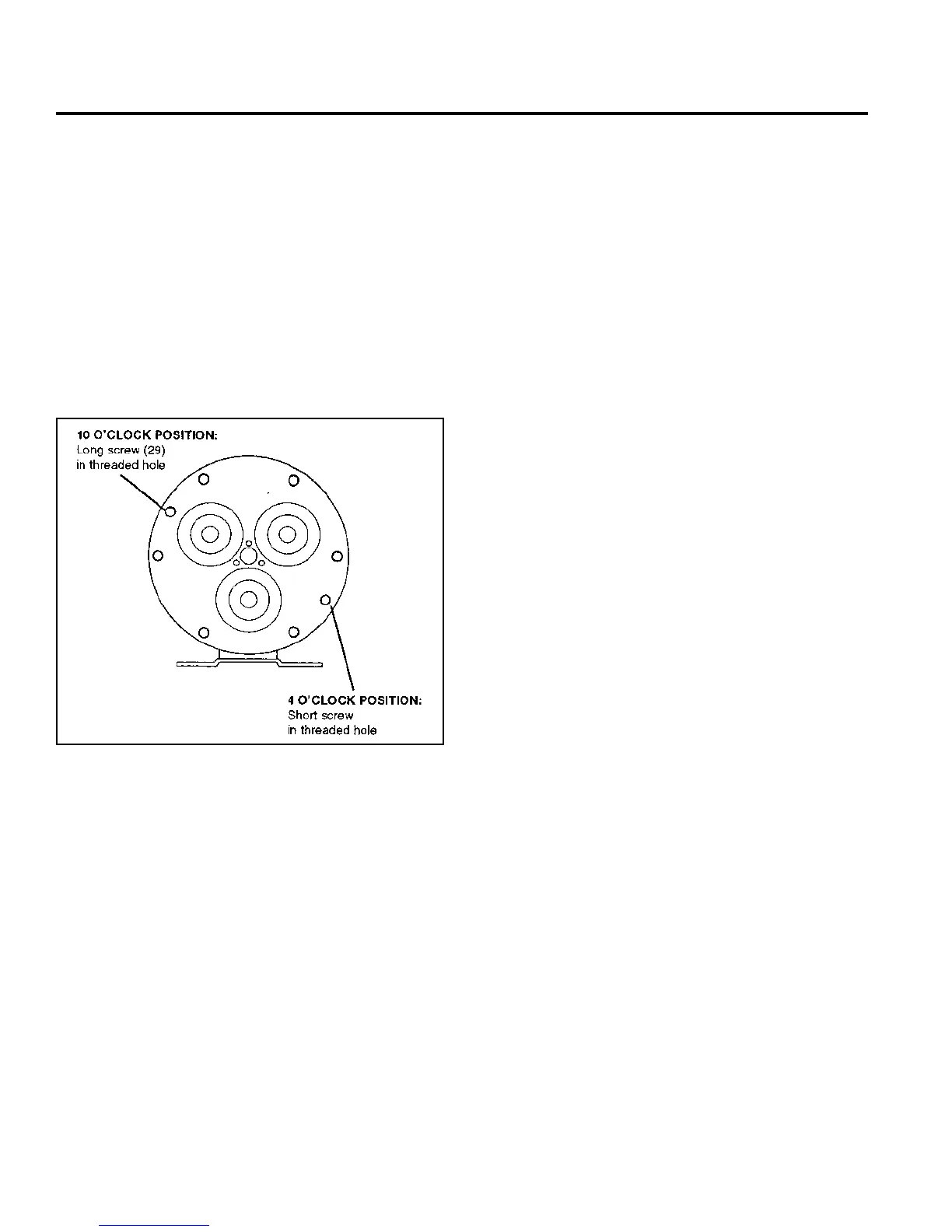

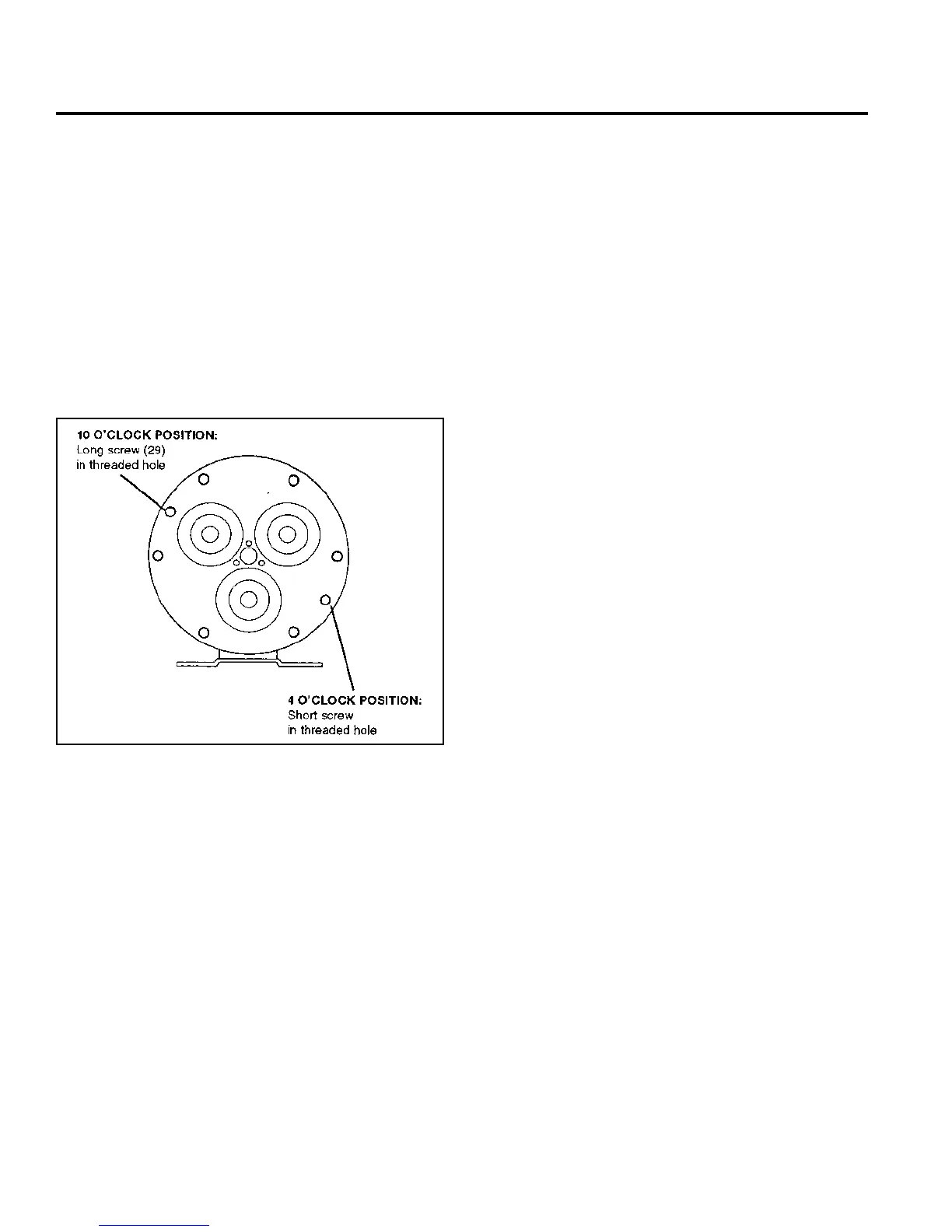

NOTE: When reassembling later, note that one bolt (29)

is 1/4 in. (5 mm) longer than the other (25 or 44). The

longer bolt must be installed in the 10 o’clock position

of the cylinder housing (24).

f. Lift off housing (30).

g. Inspect cam and bearings (62), and bearing race in rear of

housing. If bearings are pitted or binding, or if housing race

is worn, replace them both.

NOTE: The numbers in parentheses are the Reference

Numbers on the exploded view illustrations found in this

manual and also in the Parts Manual.

CAUTION: Do not disassemble the hydraulic end of the

pump unless you are a skilled mechanic. For assistance,

contact Wanner Engineering (TEL 612-332-5681 or FAX

612-332-6937) or the distributor in your area.

CAUTION: The two bolts (29; 25 or 44) that screw through

the back of the housing into the cylinder housing (24) hold

the housing to the pump housing. Do not remove them

except when repairing the hydraulic end.

NOTE: The following service procedures refer several times

to the Wanner Tool Kit (P/N A03-175-1101). We strongly

urge you not to try to repair the hydraulic end of the pump

without using the tools in this kit (available from Wanner

or your local distributor).

2. Disassemble Pistons

a. With pump housing removed (see above), turn unit over and

set it on flat surface, piston side down.

b. With diaphragms removed (see Fluid-End Service Section),

reinsert follower screw (17) into hole in one of valve plungers

(54). Tap screw lightly with hammer and plunger (21) should

slip off valve plunger (54).

Hydraulic piston assembly (50-59) can now be disassembled.

Inspect all parts, and replace all O-rings and any other parts

that are worn or damaged.

c. Repeat step b. for remaining pistons.

NOTE: When you reassemble the hydraulic piston, use

new plungers (21). They are press-fit onto the valve

plungers (54) and are not reusable.

3. Reassemble Pistons

a. Drop ball (58) into each opening in bottom of piston

assembly (59).

b. Insert retaining washer (57) and O-ring (56) to hold balls in

place.

c. Insert valve plunger (54) into valve cylinder (55). Slide

spring (53) over plunger, inside valve cylinder.

d. Insert O-ring (52) into spring retainer (51).

e. Slide assembled valve cylinder, plunger, and spring (53-55)

into spring retainer (51).

f. Slide complete cylinder-and-retainer assembly (51-55) into

piston assembly (59).

g. Insert return spring (50) into piston assembly, wide end first.

This is tight fit, and can best be done by turning spring in

counterclockwise.

h. Repeat above procedure for other two pistons.

4. Reassemble Pump Housing

and Cylinder Housing

NOTE: Inspect the shaft seals (64) before continuing. If

they look damaged in any way, replace them (remove by

pounding them out from inside the pump housing). Both

seals should be replaced at the same time. Clean the bore

in the housing using emery cloth or ScotchBrite™.

a. Place cylinder housing (24) face-down on flat surface.

b. Insert assembled pistons (50-59) into cylinder housing.

Holes on foot end of pistons should all point toward center

of casting.

c. Note location of outer ring of holes in cylinder housing and

in pump housing flange (in particular, holes where bolts (29)

and (25 or 44) will be installed).

d. Stand camshaft assembly (62) on cylinder housing (24).

CAUTION: The pilot bearing MUST be properly nested

in the bearing race during assembly. If misaligned, the

bearing will be damaged and the pump will fail within

the first hours of operation.

Loading...

Loading...