12

D10-991-2400B

D/G-10 Service (Fluid End)

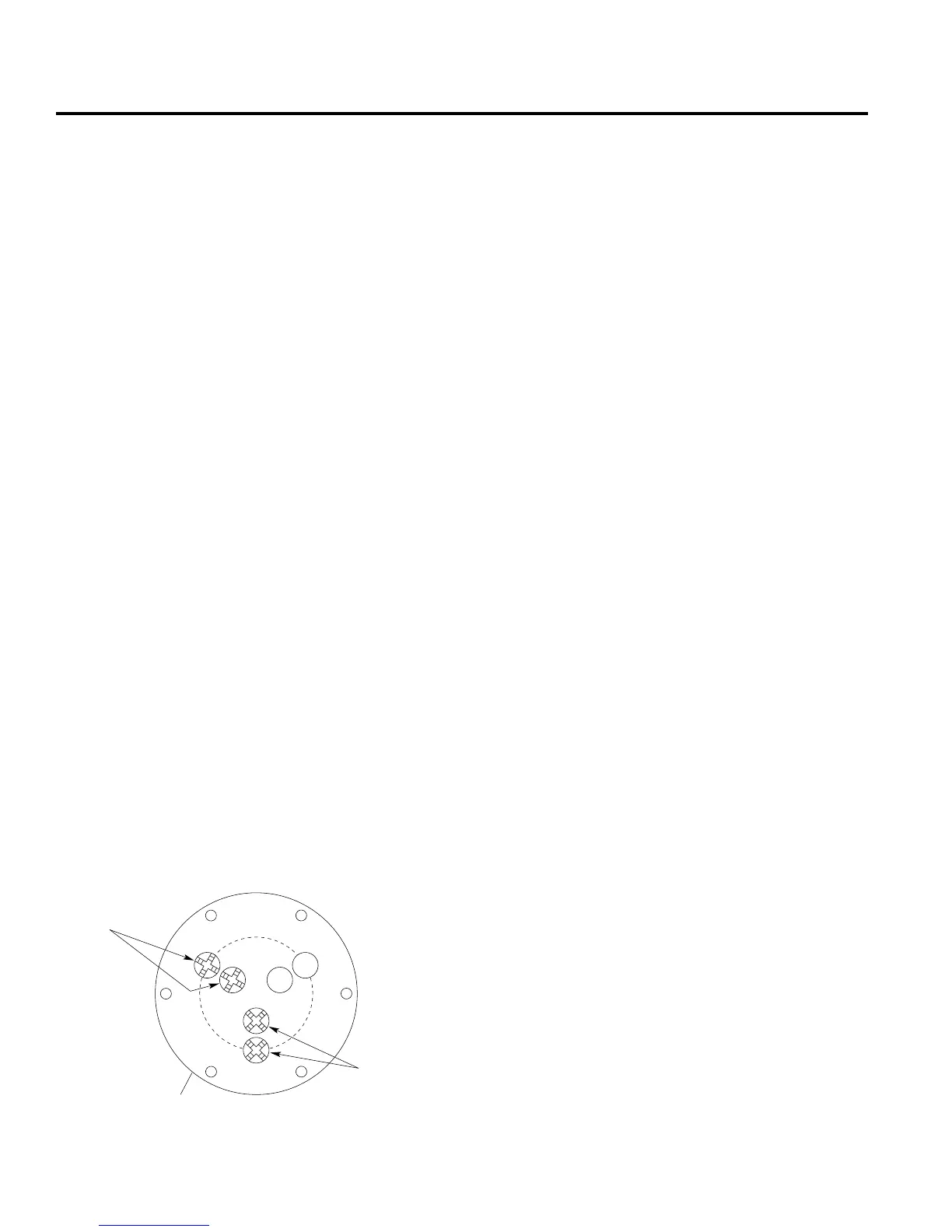

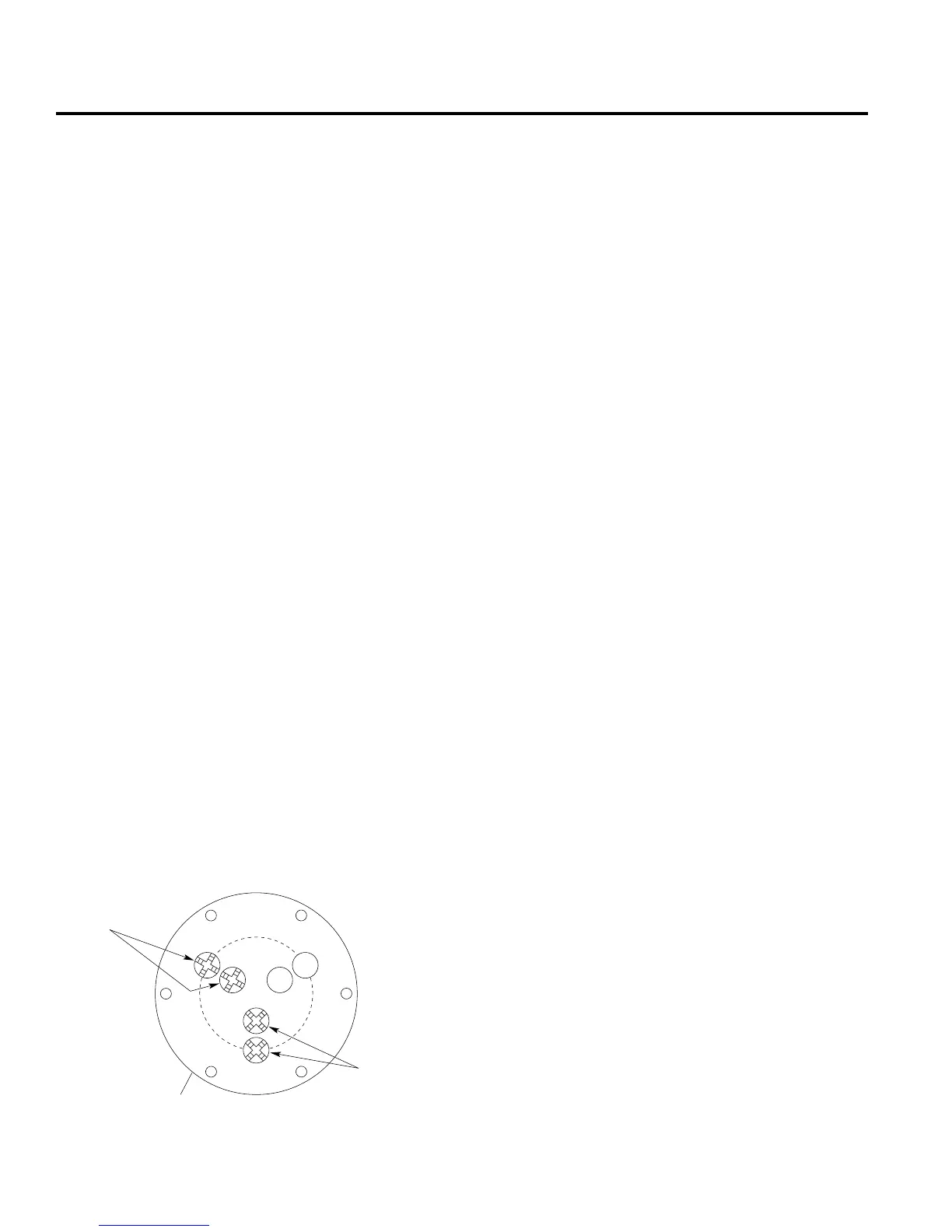

INCORRECT:

Retainer legs

pointing toward

center of pump.

Valve Retainer Orientation

In Valve Plate

W0237A

Valve plate (16)

CORRECT:

Retainer legs

45 degrees

off-center

of pump.

2. Inspect Valves (10-15, 39)

*NOTE: For non-metallic slurry duty pumps, see the insert

to this manual for fluid valve service (Step 2), then proceed

to Step 3 in this manual for remaining service steps.

The three inlet and three outlet valve assemblies are identical

(but face in opposite directions). Inspect each valve as

follows:

a. Check spring retainer (15), and replace if worn.

Note: if your pump has either abrasive duty valve

assemblies or a non-metallic pump head there will be

a plastic dampening washer (39) at the bottom of each

seat. Inspect each one for wear or cracks and replace

if necessary.

b. Check valve spring (13). If it is shorter than new spring,

replace it (don’t just stretch old spring).

c. Check valve poppet (12). If worn excessively, replace it.

NOTE: If your pump has plastic spring retainers, there

is a tetra seal (flat O-ring, 14) between the retainer (15)

and valve seat (11).

d. Remove valve seat (11). Seat remover is included in Wanner

Tool Kit. Inspect valve seat for wear, and replace it if

necessary.

e. Reinstall valve assemblies:

• Clean valve ports and shoulders with emery cloth, and

lubricate them with lubricating gel or petroleum jelly.

• Install O-ring (10) on valve seat (11).

• Inlet (3 center valves). Inser t spring retainer (15) into

valve plate, then insert spring (13), valve (12), and

valve seat (11). If pump has plastic spring retainers,

flat O-ring (14) goes between retainer and seat.

Insert dampening washer (39) if included in valve

assembly.

• Outlet (3 outer valves). Insert dampening washer (39)

if included in valve assembly. Insert valve seat, valve,

and spring, then retainer. If pump has plastic retainers,

install flat O-ring between retainer and seat. If pump has

metal spring retainers in outlet valves, position them

so leg does not point toward center of pump (refer to

illustration below).

3. Inspect and Replace

Diaphragms (20)

If necessary to ser vice the diaphragms, remove the two socket-

head cap screws (41) that secure the valve plate (16) to the

cylinder casting (24). Inspect the valve plate in the same manner

as you did the manifold.

a. Lift diaphragm by one edge, and turn pump shaft until

diaphragm pulls up. This will expose machined cross-holes

in plunger shaft behind diaphragm.

b. Insert Allen wrench through one of holes, to hold diaphragm

up. Proper size tool is included in Wanner Tool Kit.

c. Remove screw (17), O-ring (18), and follower (19) in center

of diaphragm.

d. Remove diaphragm, and inspect it carefully. Ruptured

diaphragm generally indicates pumping system problem,

and replacing only diaphragm will not solve larger problem.

Inspect diaphragm for following:

• Half-moon marks. Usually caused by cavitation of pump

(refer to “Troubleshooting” section).

• Concentric circular marks. Usually caused by cavitation

of pump (refer to “Troubleshooting” section).

• Small puncture. Usually caused by sharp foreign object

in fluid, or by ice particle.

• Diaphragm pulled away from center screw or from

cylinder sides. Usually caused by fluid being frozen in

pump, or by over pressurization of pump.

• Diaphragm becoming stiff and losing flexibility. Usually

caused by pumping fluid that is incompatible with

diaphragm material.

• Slice in ridge of diaphragm. Occurs when Viton

diaphragm is operated at cold temperatures.

• Diaphragm edge chewed away. Usually caused by over

pressurizing system.

e. Inspect plunger (21) for any rough surfaces or edges. Do

not remove plunger from plunger shaft. Smooth surfaces

and edges as necessary with emery cloth or fine file.

CAUTION: If a diaphragm has ruptured and foreign

material or water has entered the oil reservoir, do not

operate the pump. Check all diaphragms, then flush the

reservoir completely (as outlined below) and refill it with

fresh oil. Never let the pump stand with foreign material

or water in the reservoir, or with the reservoir empty.

f. Install new diaphragm (or reinstall old one, as appropriate),

ridge side out.

g. Clean screw (17) and remove any oil from it. Apply medium-

strength threadlocker to screw. Reinstall screw and follower

(19), and a new O-ring (18). Tighten to 18 in.-lbs (2.0 N-m).

h. Repeat above inspection procedure (and replacement, if

necessary) with other two diaphragms.

Loading...

Loading...