10

D10-991-2400B

22

24

W0217B

3433

35

29

5

30

46

27

26

45

44

25

5

37

36

32

17

18

19

21

20

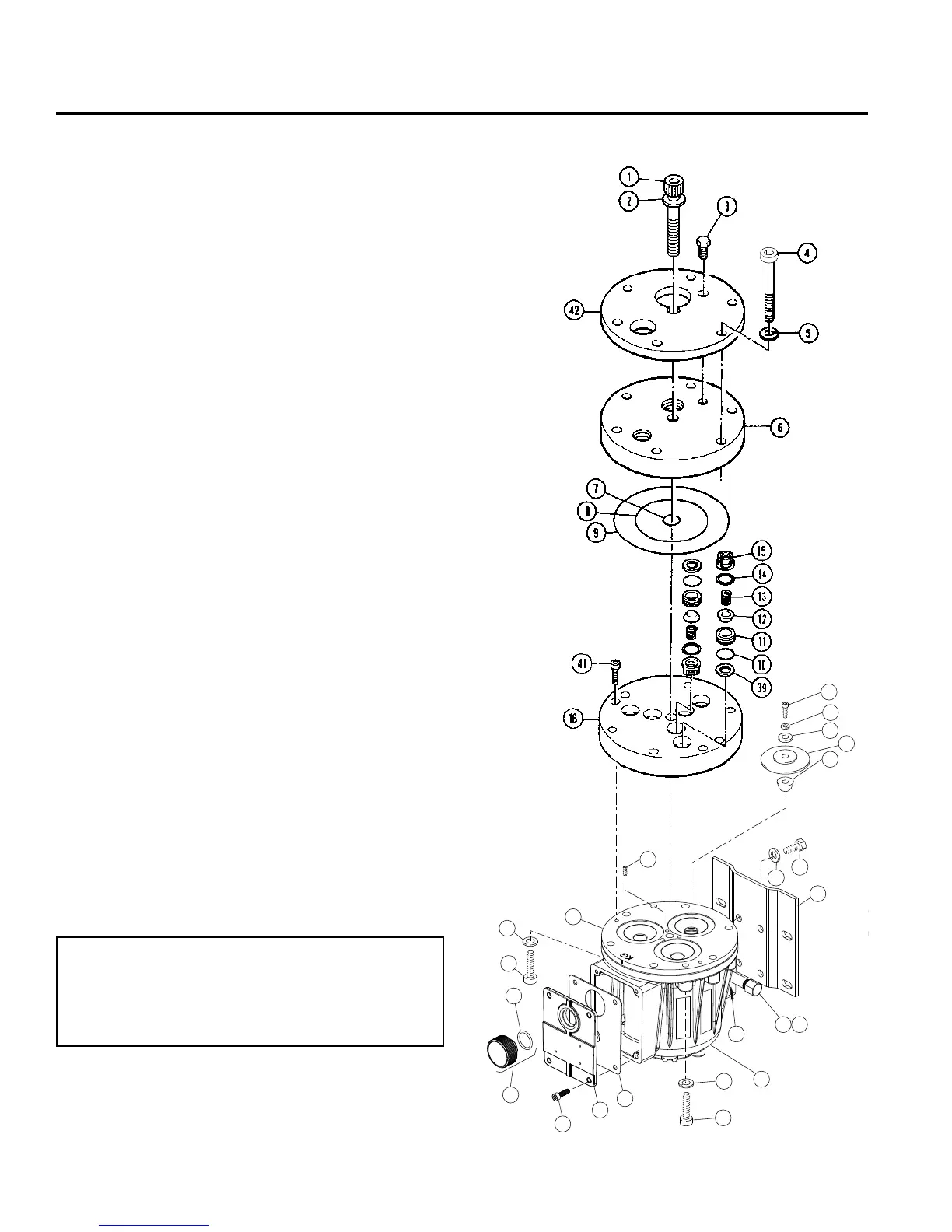

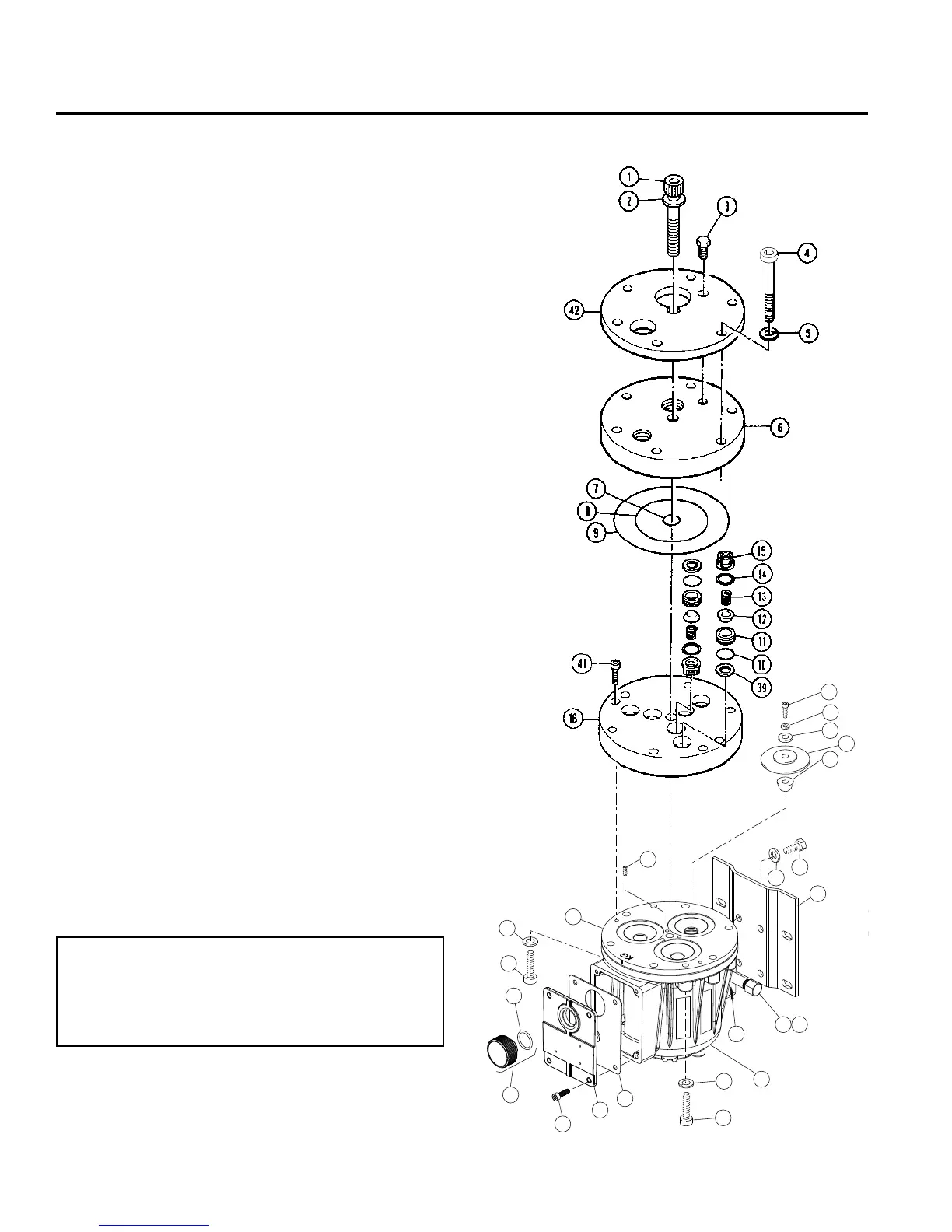

D/G-10 Service (Fluid End)

Model D-10/G-10

With Non-Metallic Pump Head*

NOTE: The numbers in parentheses are the Reference

Numbers on the exploded view illustrations found in this

manual and also in the Parts Manual.

This section explains how to disassemble and inspect all

easily-serviceable parts of the pump. Repair procedures for

the hydraulic end (oil reservoir) of the pump are included in a

later section of the manual.

CAUTION: Do not disassemble the hydraulic end unless

you are a skilled mechanic. For assistance, contact Wanner

Engineering (TEL 612-332-5681 or FAX 612-332-6937) or

the distributor in your area.

CAUTION: The two bolts (29; 25 or 44) that screw through

the back of the housing into the cylinder casting hold the

casting over the hydraulic end of the pump. Do not remove

them except when repairing the hydraulic end.

1. Remove Manifold (6), Valve

Plate (16)

a. Remove all nuts (31) and bolts (4) around the manifold. Do

not remove two bolts (29; 25 or 44) that are installed through

back of pump housing.

b. Use 3/8-in. (10-mm) hex Allen wrench to remove center

bolt (1) and its washer (2).

CAUTION: Do not turn the pump drive shaft while the

manifold and valve plate are off the pump, except

when removing diaphragms or repriming the hydraulic

cells.

c. Remove manifold (6), and support plate (42) [non-metallic

pump head only]. Valve plate (16) will remain on cylinder

casting (24).

d. Inspect manifold for warping or wear around inlet and outlet

ports. If wear is excessive, replace manifold.

To check if manifold is warped, remove O-rings and

place straightedge across it. Warped manifold should be

replaced.

*NOTE: For non-metallic slurry duty pumps, see the

insert to this manual for fluid valve service (Step 2),

then proceed to Step 3 in this manual for remaining

service steps.

Loading...

Loading...