Configuration and Calibration Guide HD0679 Rev 1.2.0 29

Chapter 3 Sensor Integration and Material Calibration

1 Sensor Integration

The sensor may be integrated into a process in one of three ways:-

• The sensor may be configured to output a linear value of between 0-100 Unscaled units

with a material calibration being performed in an external control system.

Or

• The sensor may be internally calibrated using the Hydro-Com sensor configuration and

calibration software to output an absolute moisture percentage value.

Or

• The sensor could also be used to output a target value

Software development tools are available from Hydronix for system designers who wish to

develop their own interface.

For full details about how to integrate the sensor into a control system or process see

document EN0077 ‘Moisture control methods for batching’.

2 Introduction to Material Calibration

2.1 The “Unscaled” Value

When it is manufactured, each sensor is individually calibrated in a controlled environment so

that a zero (0) value relates to the measurement in air and 100 relates to water. This is used

to give a raw output value from a Hydronix sensor which ranges from 0 to 100 and is called

the Unscaled value.

2.2 Why Calibrate?

Hydronix Microwave Moisture Sensors measure the electrical properties of a material. Each

material has its own unique electrical characteristics and as a result a calibration process

must be performed to output a true moisture/Brix value. As the moisture in a material varies

the sensor detects the changes and the Unscaled value is adjusted accordingly. Due to every

material having a different electrical property the Unscaled value at a certain moisture % will

result in a different Unscaled value for each material.

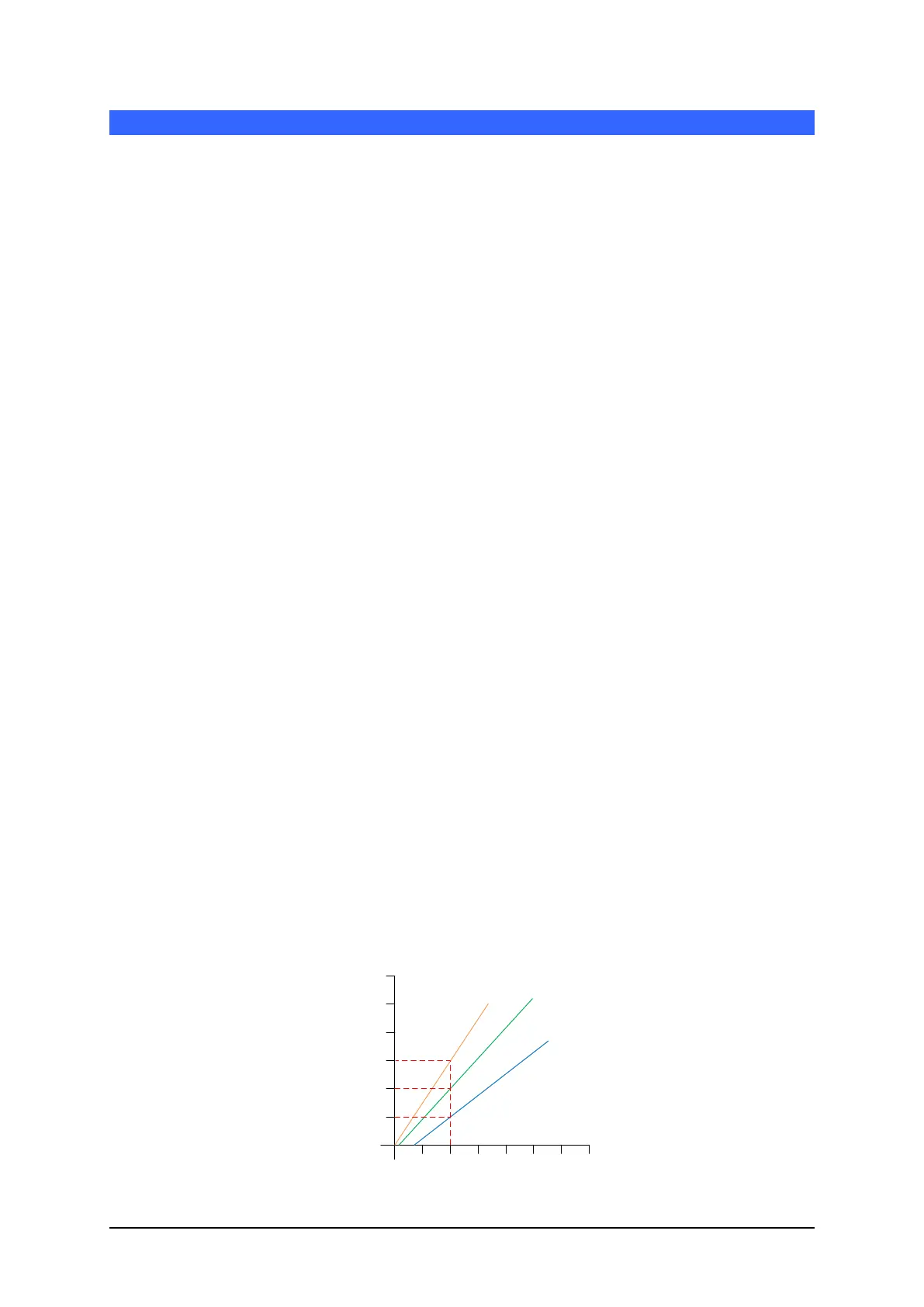

Figure 14: Calibrations for 3 Different Materials shows the calibration line for three different

materials. It can be seen that for each material when the Unscaled value is at 20 the

corresponding Moisture % is different. For material A an Unscaled value of 20 corresponds to

a moisture of 15%. At the same Unscaled value for Material B the moisture is 10%.

Sensor Unscaled

Moisture %

10 20 30 40

50

60 70

30

25

20

15

10

5

Material A

Material B

Material C

Figure 14: Calibrations for 3 Different Materials

Loading...

Loading...