Chapter 3 Sensor Integration and Material Calibration

36 Configuration and Calibration Guide HD0679 Rev 1.2.0

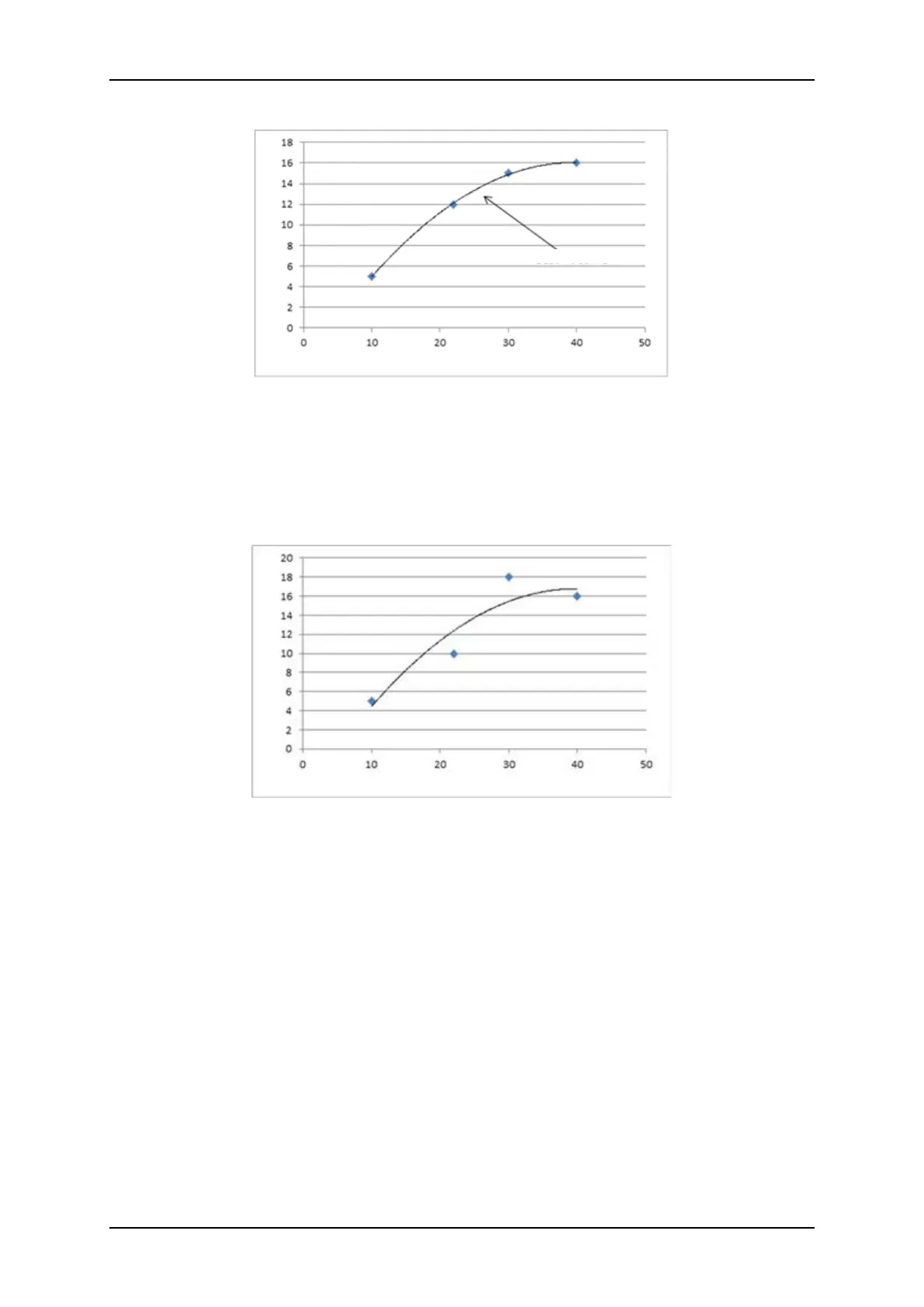

Best Fit Curve

Material Moisture %

Sensor Unscaled output

Figure 20: Example of a Good Quadratic Calibration

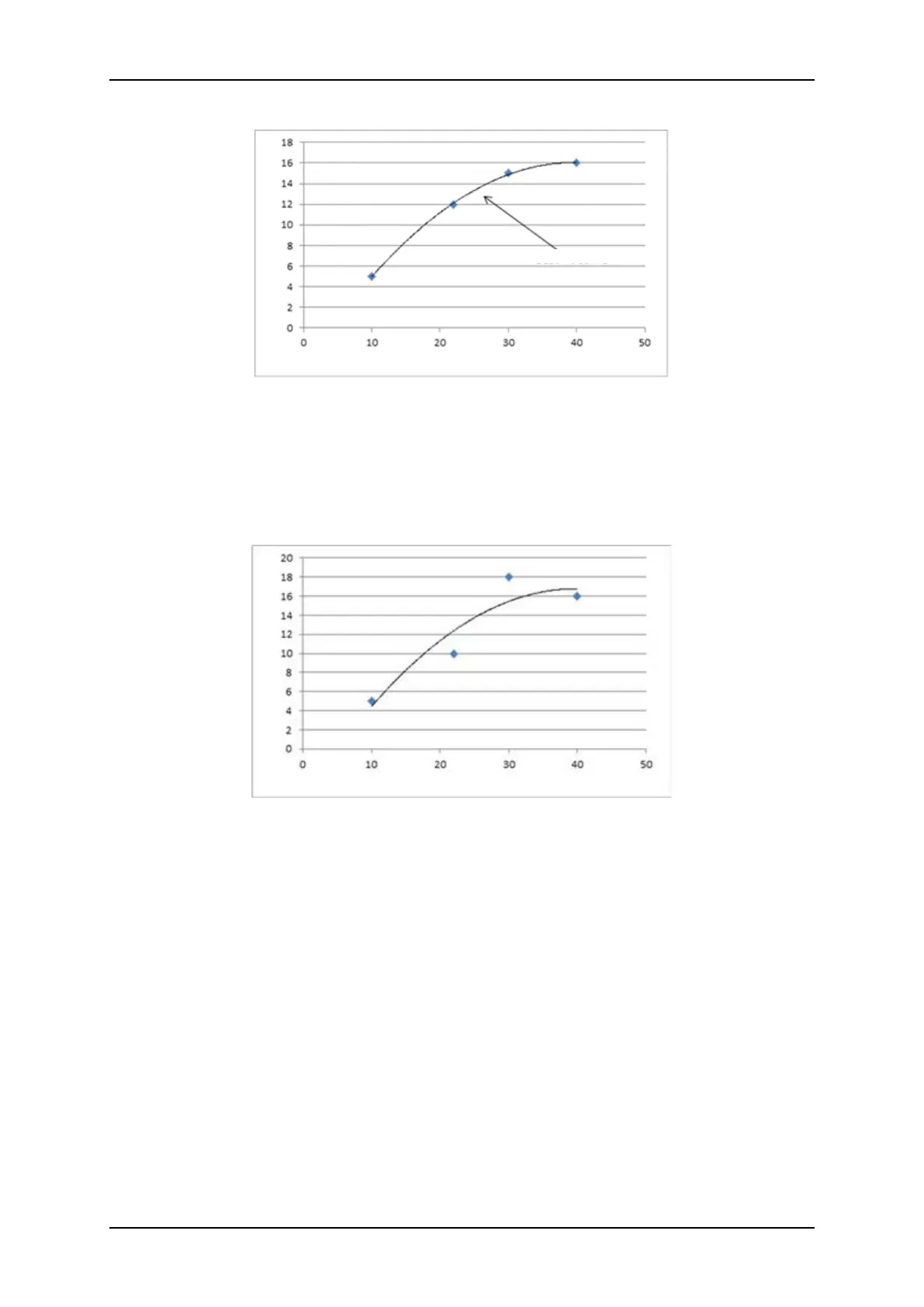

Figure 21 is an example of a poor calibration. It is evident that the calibration points are not

close to the curve fit and this indicates that there are possible sampling and laboratory errors.

This calibration would need to be completed again.

Material Moisture %

Sensor Unscaled Output

Figure 21: Example of a Bad Quadratic Calibration

8 Calibrating a sensor in a mixer

When a sensor has been installed in a mixer, with multiple materials, and it is required to output

moisture % it is not always possible to perform a standard calibration process. This is especially

true in concrete production. Taking samples of the finished wet concrete and performing a bake-

out to determine the moisture % is not reliable due to the chemical reactions and safety issues.

The following method can be used to calibrate in these situations.

1. To calibrate in the mixer the moisture % of all the dry materials must be calculated using

a suitable calibrated moisture sensor or by using laboratory facilities.

In this example the dry mix material moistures and weights are:

Sand = 950kg at 8% moisture

Gravel = 1040kg at 2.5% moisture

Cement = 300kg at 0% moisture (Should always be 0%)

Loading...

Loading...