Sensor Integration and Material Calibration Chapter 3

Configuration and Calibration Guide HD0679 Rev 1.2.0 39

5. The average of the laboratory results and the Filtered Unscaled value make up one

calibration point.

6. Steps 3-5 should be repeated for additional calibration points. Ideally calibration points

should be collected to cover the entire expected Brix range of the material.

Hydro-Com software should be used to calculate the calibration coefficients and to update the

sensor with the calibration.

9.1 Good/Bad Brix Calibration

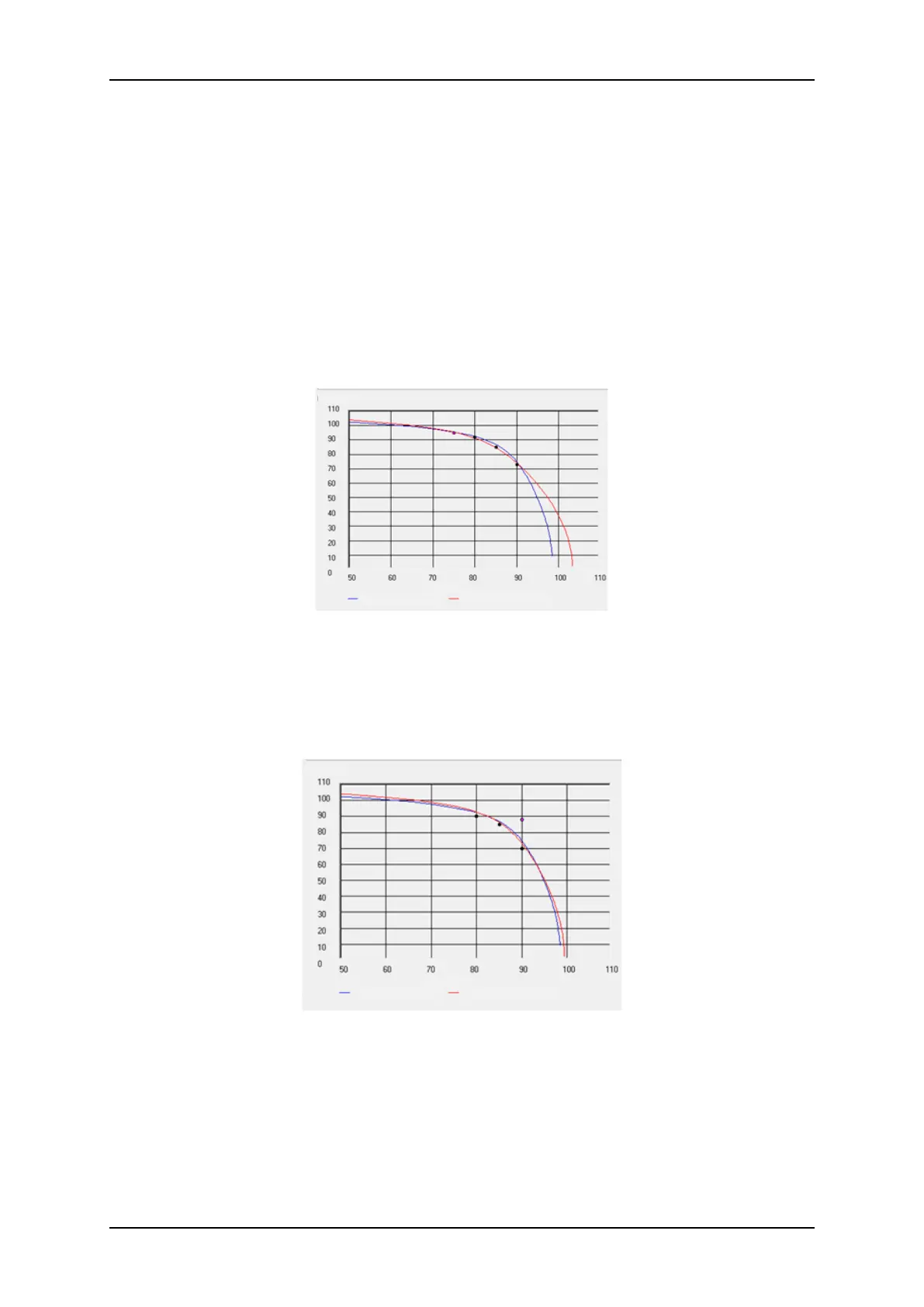

A good Brix calibration is achieved by analysing the material over the working range. A good

spread of points is necessary to provide higher accuracy.

Figure 22 shows a good calibration with all points close to the best fit curve.

Improved Calibration

Current Calibration

Brix

Unscaled

Figure 22: Example of a Good Brix Calibration

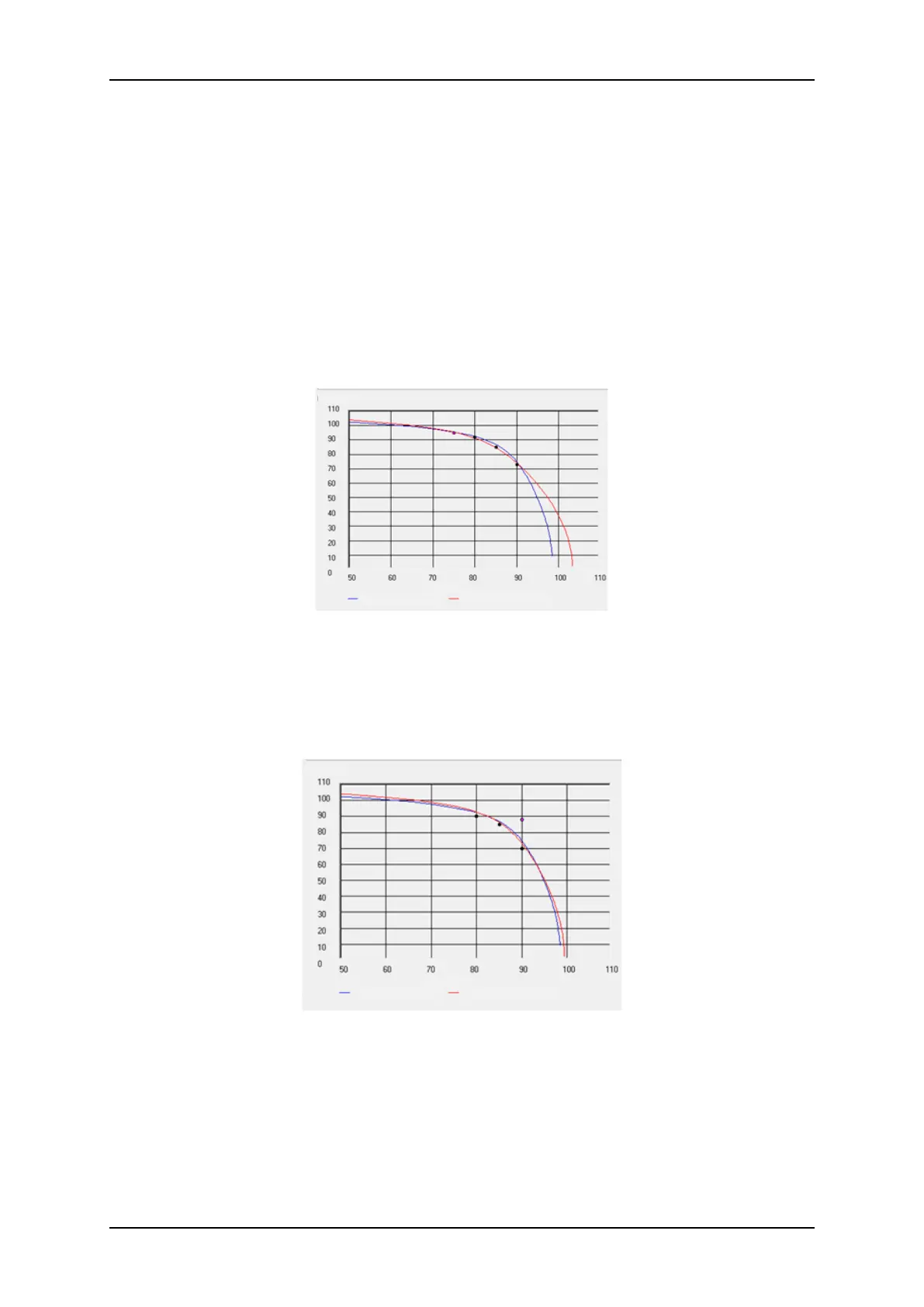

Figure 23 is an example of a bad Brix calibration, this is evident as the points are not all close

to the best fit curve.

Unscaled

Brix

Improved Calibration

Current Calibration

Figure 23: Example of a Bad Brix Calibration

For full details on the use of Hydro-Com see user guide HD0682.

Loading...

Loading...