- 4 -

Hazardous Substance Alert

1. Always drain and flush the pump before servicing or

disassembling for any reason (see instructions).

2. Always drain and flush pumps prior to returning unit

for repair.

3. Never store pumps containing hazardous chemicals.

4. Before returning pump for service/repair, drain out all

liquids and flush unit with neutralizing liquid. Then,

drain the pump. Attach tag or include written notice

certifying that this has been done. Please note that it

is illegal to ship or transport any hazardous chemicals

without United States Environmental Protection

Agency Licensing.

¤

OIL

THE ULTIMATE PUMP LUBRICANT

Specifically formulated SAE 30 weight,

high-grade, non-detergent pump oil

with special agents for the prevention of:

¥ Scuff and wear

¥ Moisture

¥ Oxidation

¥ Foaming

¥ Rust

1. After use, flush the pump with clean water.

2. Hypro diaphragm pumps come with oil in the

crankcase. Hypro recommends

changing oil after 40 hours of break-in

operation and every three months or

500 hours, whichever comes first. Use

Hypro Oil (part number 2160-0038).

Hypro Oil is a specially formulated,

high-grade, nondetergent, SAE 30

weight oil designed to prolong pump life.

To drain the oil from the pump, remove the oil drain

plug and rotate the shaft until the oil stops flowing out.

To fill the pump with oil, slowly pour the oil into sight

tube while turning the pump shaft. Turning the pump

shaft purges all the air out of the crankcase. Always

change oil when replacing diaphragms.

3. For winter storage or if a freezing condition will be

encountered, flush pump with a 50/50 mixture of

water and antifreeze.

Valve Replacement

Occasionally debris can cause the valves to not seat

properly or damage the o-rings. To check for this problem,

follow these steps.

1. Remove valve retainers and valve holders. W

ith

holders removed, the valves can readily be removed

and checked for debris or wear. Check o-rings as well.

See the parts list for appropriate valve and o-ring kits.

2. Replace the necessary parts and reassemble.

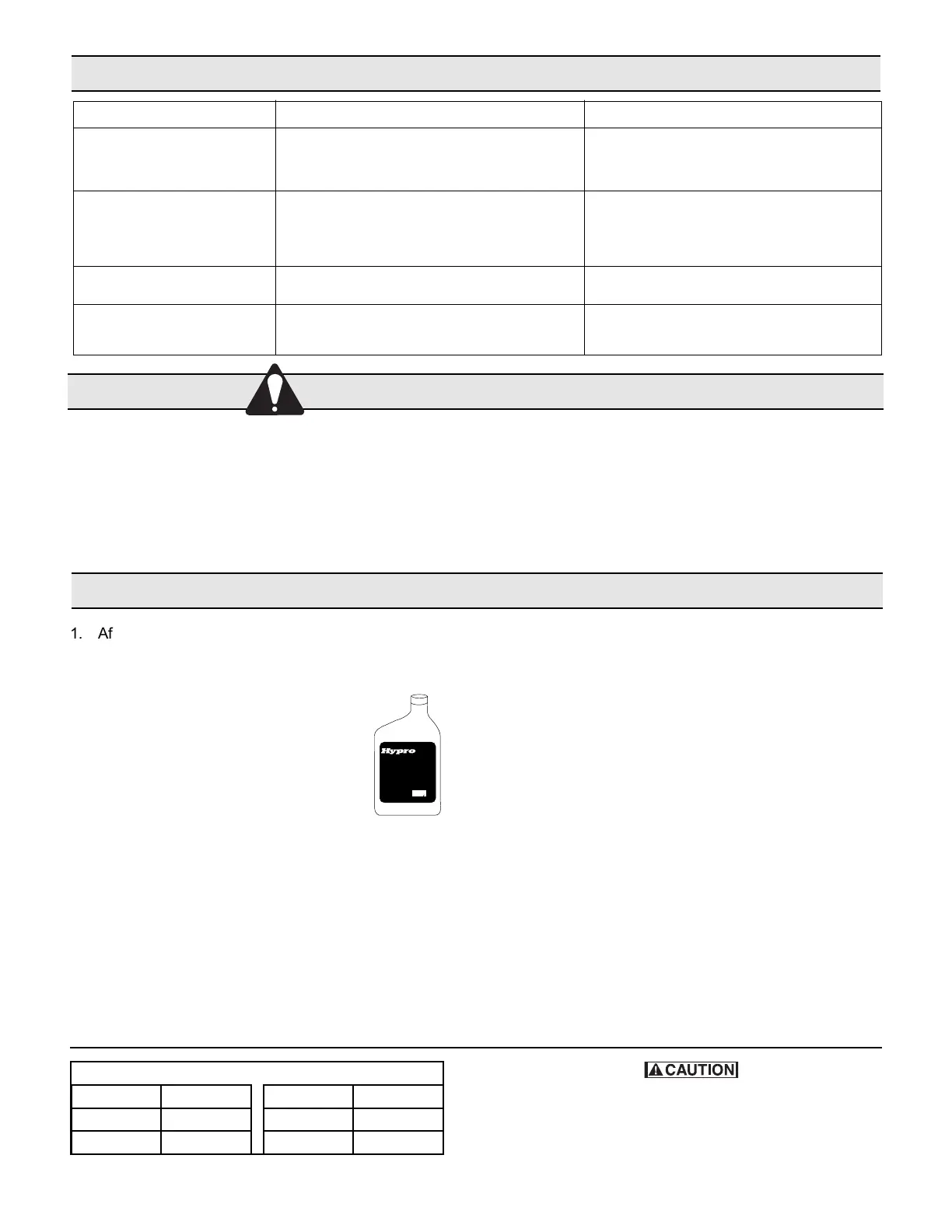

SYMPTOM PROBABLE CAUSE(S) CORRECTIVE ACTION

The pump does not draw water. One or more valves are seating improperly. Remove valve and check for debris.

Suction line is plugged or collapsed. Clogged strainer

. Examine suction line. Clean strainer.

The liquid flow is The charge in the pulsation Check pressure in pulsation damper

irregular. damper is incorrect. (approximately 20% of operating pressure).

One or more valves are seating improperly. Remove valve and check for debris. Examine

the valve seatings and clean them.

Output drops and the Oil level is too low. Add oil to correct level (halfway up the sight tube).

pump is noisy.

Oil comes out of the One or more diaphragms split. Remove manifold and heads. Drain oil and clean

discharge port or oil is crankcase of water. Replace diaphragms, heads and

a milky color. manifold. Refill with Hypro Oil (Part No. 2160-0038).

Troubleshooting

Maintenance

Model Capacity

9910-D813 19 oz.

9910-D1064 24 oz.

Model Capacity

9910-D1265 1 qt., 10 oz.

9910-D1516 2 qts., 13.5 oz.

CRANKCASE OIL CAPACITIES

Oil crankcases capacities are approximate. Fill oil

to proper level in sight glass. Always make sure all

the air is purged out of crankcase prior to

operating.

Form L-1383 (12/11, Rev. B)

Loading...

Loading...