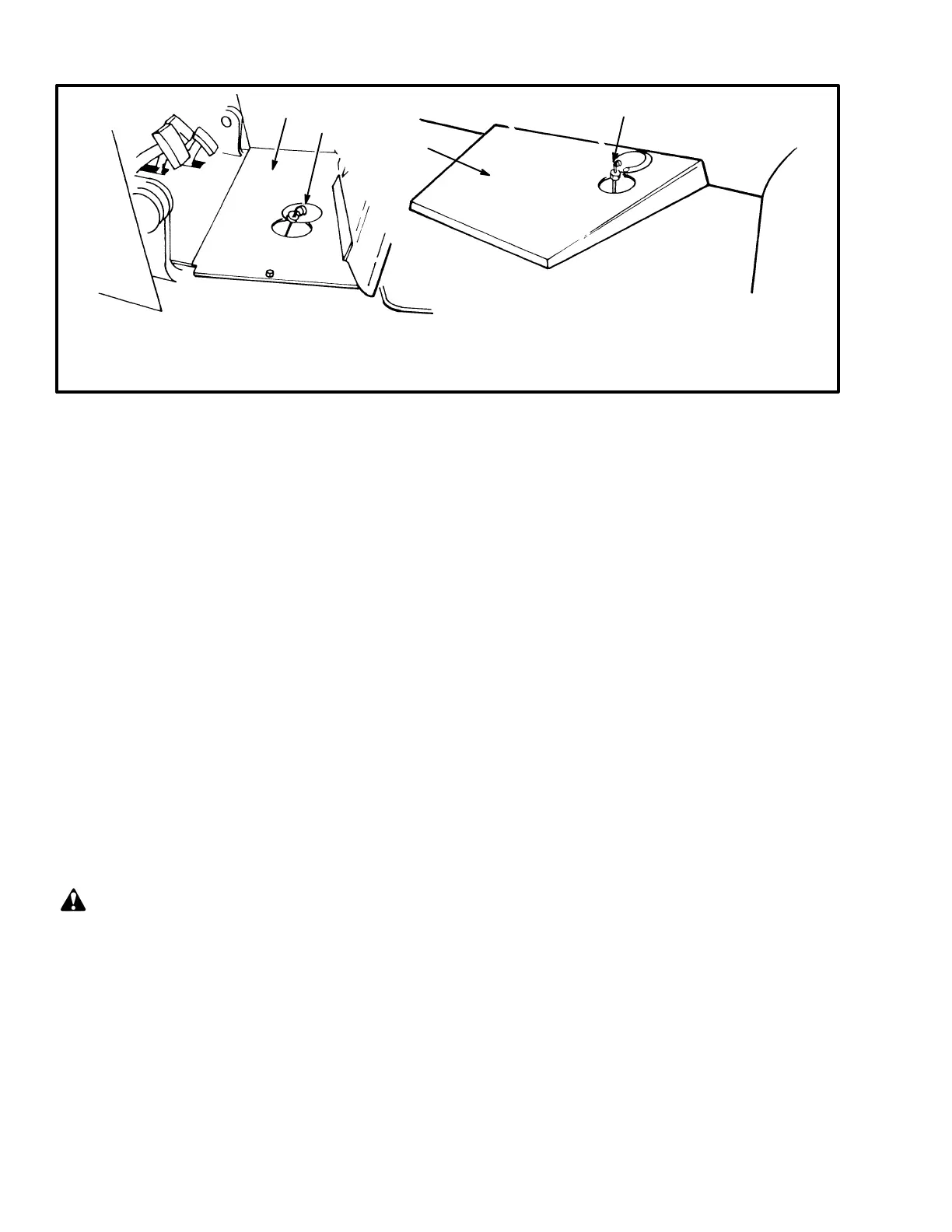

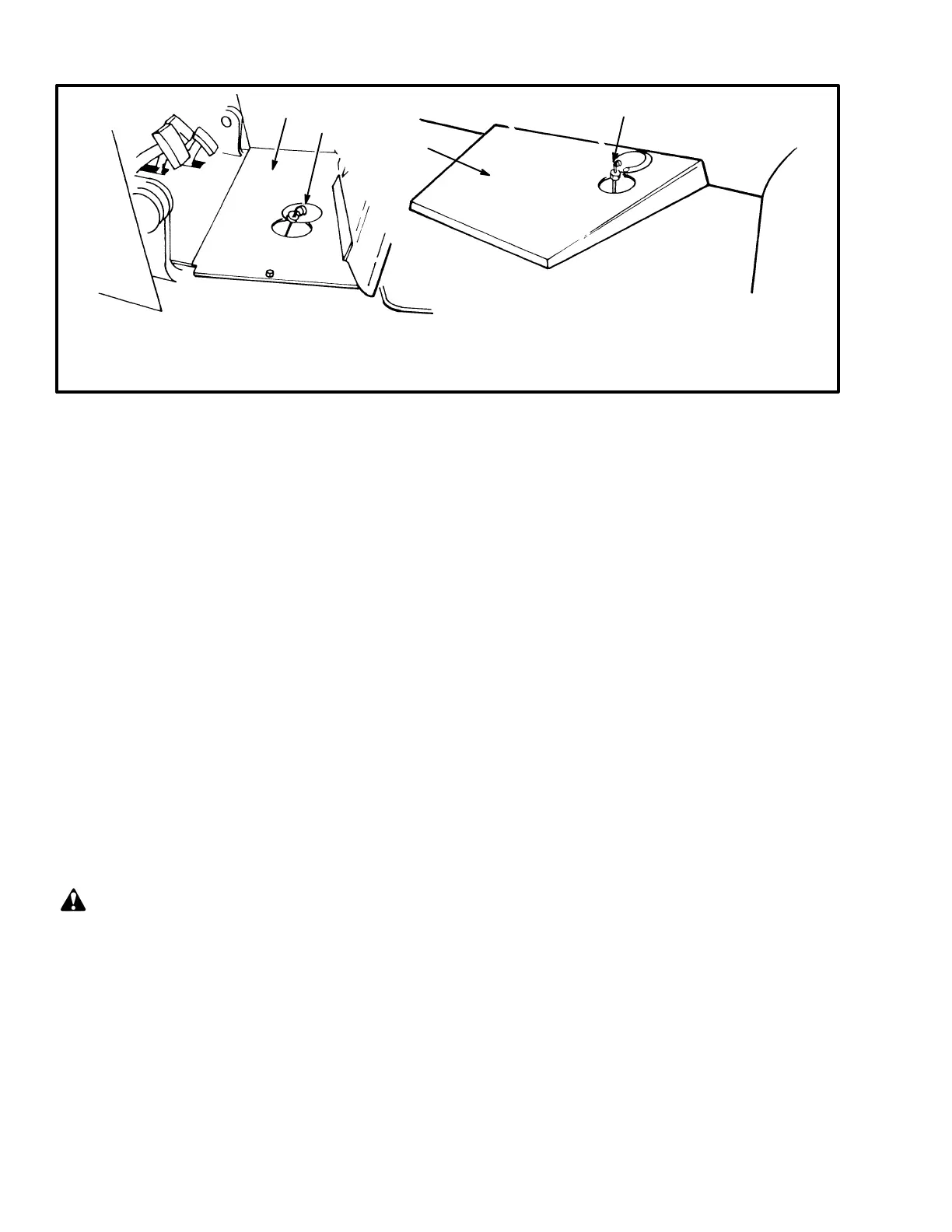

16

H70–110XL

1. DIPSTICK FOR POWERSHIFT TRANSMISSION OIL OR OIL CLUTCH SYSTEM OIL

2. DIPSTICK FOR POWERSHIFT TRANSMISSION

3. FLOOR PLATE

H135–155XL

11703

11638

1

2

3

3

FIGURE 18. CHECK THE OIL FOR THE POWERSHIFT TRANSMISSION OR OIL CLUTCH SYSTEM

Oil Level, Oil Clutch System, H3.50–5.00XL

(H70–110XL) (See FIGURE 18.)

NOTE: The oil clutch system for the H6.00–7.00XL

(H135–155XL) lift trucks does not have a dipstick be-

cause the oil clutch uses oil from the hydraulic system.

Put the direction control lever in the NEUTRAL (N)

position. Apply the parking brake. Check the oil level in

the clutch housing when the engine is running at idle

speed. The most accurate check of the oil level is when

the oil is at operating temperature. Use the correct oil as

shown in the MAINTENANCE SCHEDULE. Keep the

oil at the “FULL” mark on the dipstick.

Control Levers and Pedals

Check that the control levers for the transmission, mast

and attachment operate as described in the OPERAT-

ING MANUAL. Check that the pedals operate cor-

rectly as described in the OPERATING MANUAL.

Lift System Operation

WARNING

Lower the lift mechanism completely. Never allow

any person under a raised carriage. Do not put any

part of your body in or through the lift mechanism

unless all parts of the mast are completely lowered

and the engine is STOPPED.

Before making any repairs, use blocks and chains on

the mast weldments and carriage so that they can not

move. Make sure the moving parts are attached to a

part that does not move.

Do not try to find hydraulic leaks by putting hands

on pressurized hydraulic components. Hydraulic oil

can be injected into the body by the pressure.

Do the following checks and inspections:

a. Check for leaks in the hydraulic system. Check

the condition of the hydraulic hoses and tubes.

b. Slowly raise and lower the mast several times

without a load. Raise the mast to its full extension

height at least once. The mast components must

raise and lower smoothly in the correct sequence.

NOTE: Some parts of the mast move at different speeds

during raising and lowering.

c. The inner weldments and the carriage must lower

completely.

d. Raise the mast one metre (three feet) with a ca-

pacity load. The inner weldments and the car-

riage must raise smoothly. Lower the mast. All

moving components must lower smoothly.

e. Lower the load to approximately 0.3 metre (one

foot). Tilt the mast forward and backward. The

mast must tilt smoothly and both tilt cylinders

must stop evenly.

f. Check that the controls for the attachment oper-

ate the functions of the attachment. (See the sym-

bols by each of the controls.) Make sure all of the

hydraulic lines are connected correctly and do

not leak.

Loading...

Loading...