15

Safety Labels

WARNING

Safety labels are installed on the lift truck to give in-

formation about operation and possible hazards. It

is important that all safety labels are installed on the

lift truck and can be read.

Check that all safety labels are installed in the correct lo-

cations on the lift truck. See the PARTS MANUAL or

the FRAME section of the SERVICE MANUAL for

the correct location of the safety labels.

If new labels must be installed, use the following proce-

dure:

WARNING

Cleaning solvents can be flammable and toxic, and

can cause skin irritation. When using cleaning sol-

vents, always follow the recommendations of the

manufacturer.

a. Make sure the surface is dry and has no oil or

grease. Do not use solvent on new paint. Clean

the surface of old paint with a cleaning solvent.

b. Remove the paper from the back of the label. Do

not touch the adhesive surface.

c. Carefully hold the label in the correct position

above the surface. The label cannot be moved af-

ter it touches the surface. Put the label on the sur-

face. Make sure that all air is removed from under

the label and the corners and edges are tight.

HOW TO MAKE THE CHECKS WITH THE

ENGINE RUNNING

WARNING

FASTEN YOUR SEAT BELT! The seat belt is in-

stalled to help the operator stay on the truck if the lift

truck tips over. IT CAN ONLY HELP IF IT IS FAS-

TENED.

Make sure that the area around the lift truck is clear be-

fore starting the engine or making any checks of the op-

eration. Be careful when making the checks. If the lift

truck is stationary during a check, apply the parking

brake and put the transmission in NEUTRAL. Make the

checks carefully.

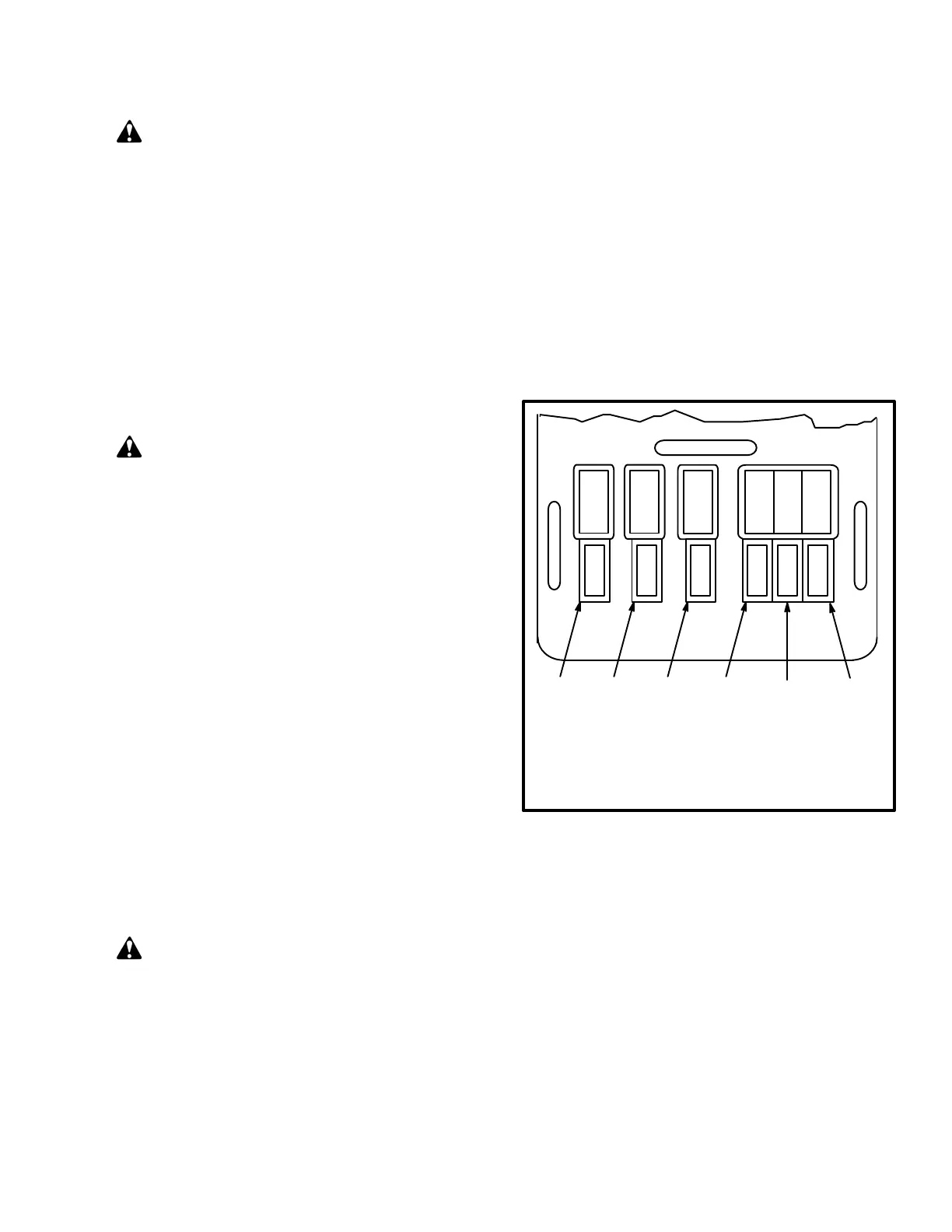

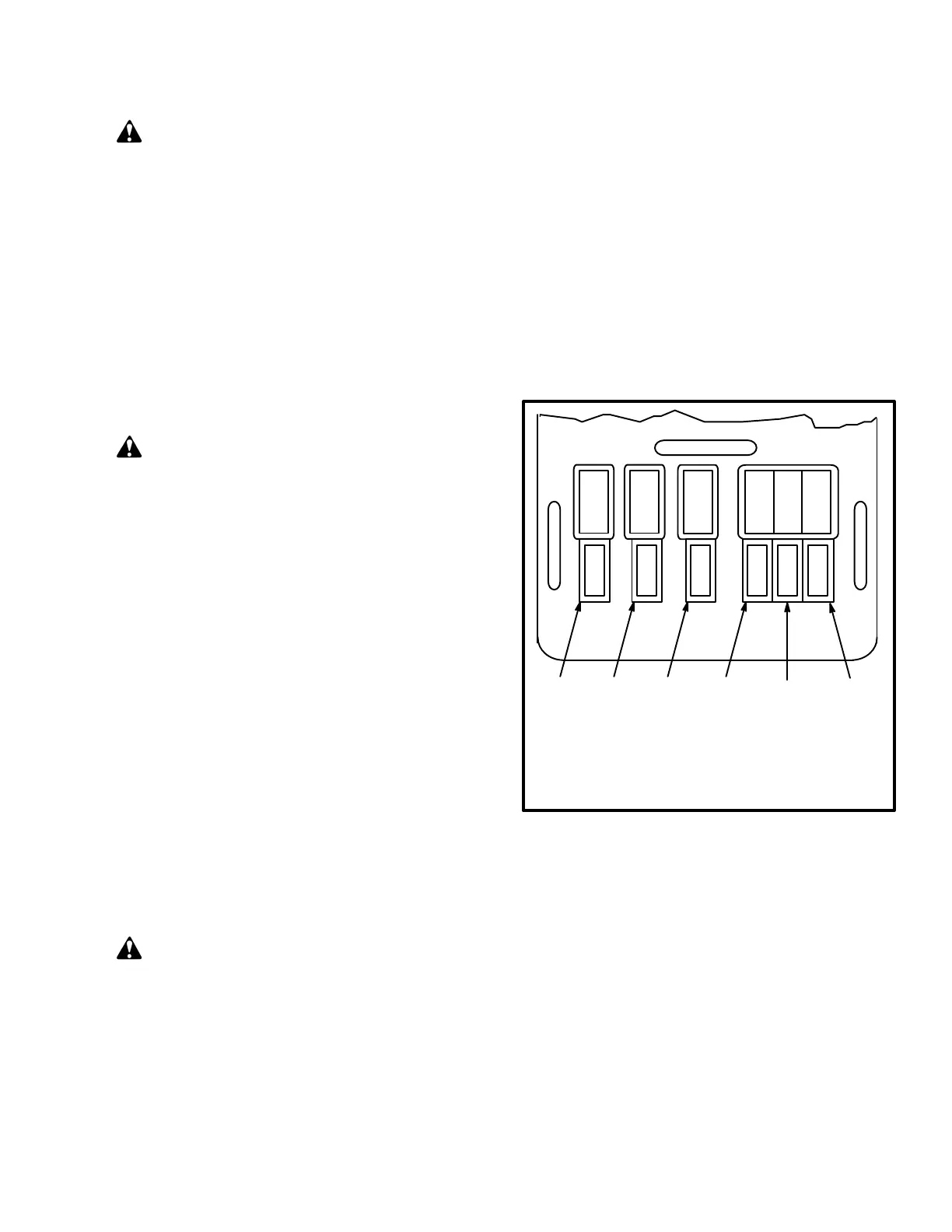

Gauges, Lights, Horn, and Fuses

Start the engine. Check the gauges and lights for correct

operation as described in the OPERATING MAN-

UAL. Check the operation of the horn. If any of the

lights or gauges do not operate correctly, check the

fuses. The fuses are under the instrument panel on the

left side of the cowl. See FIGURE 17.

12200

LIGHT

DSL

COLD

START

HORN

GAGES

XMSN

SHIFT

12

3456

1. GAUGES

2. TRANSMISSION SOLENOIDS

3. HORN

4. COLD START AID (DIESEL)

5. LIGHTS

6. OTHER OPTIONS

LH

&

GAGES

RH

7.5A

FIGURE 17. FUSES

5

25A

30A

10A

5A

5A

PLNG

Oil Level, Powershift Transmission

(See FIGURE 18.)

Apply the parking brake. Check the oil level in the

powershift transmission when the engine is running at

idle speed. If the lift truck has a direction control lever,

put the direction control lever in the NEUTRAL (N) po-

sition. Use the correct oil shown in the MAINTE-

NANCE SCHEDULE. Keep the oil level at the “FULL”

mark on the dipstick. The most accurate check of the oil

level is when the transmission is at operating tempera-

ture.

Loading...

Loading...