19

the new filter. Turn the filter until the gasket touches,

then tighten

1

/

2

to

3

/

4

turn with your hand. Start the en-

gine. Check the area around the oil filter for leaks.

DRIVE BELTS

Check the drive belts for wear and damage. When a pair

of drive belts are used, they must be replaced as a pair.

When a pair of drive belts are used, adjust the tension for

the tightest belt.

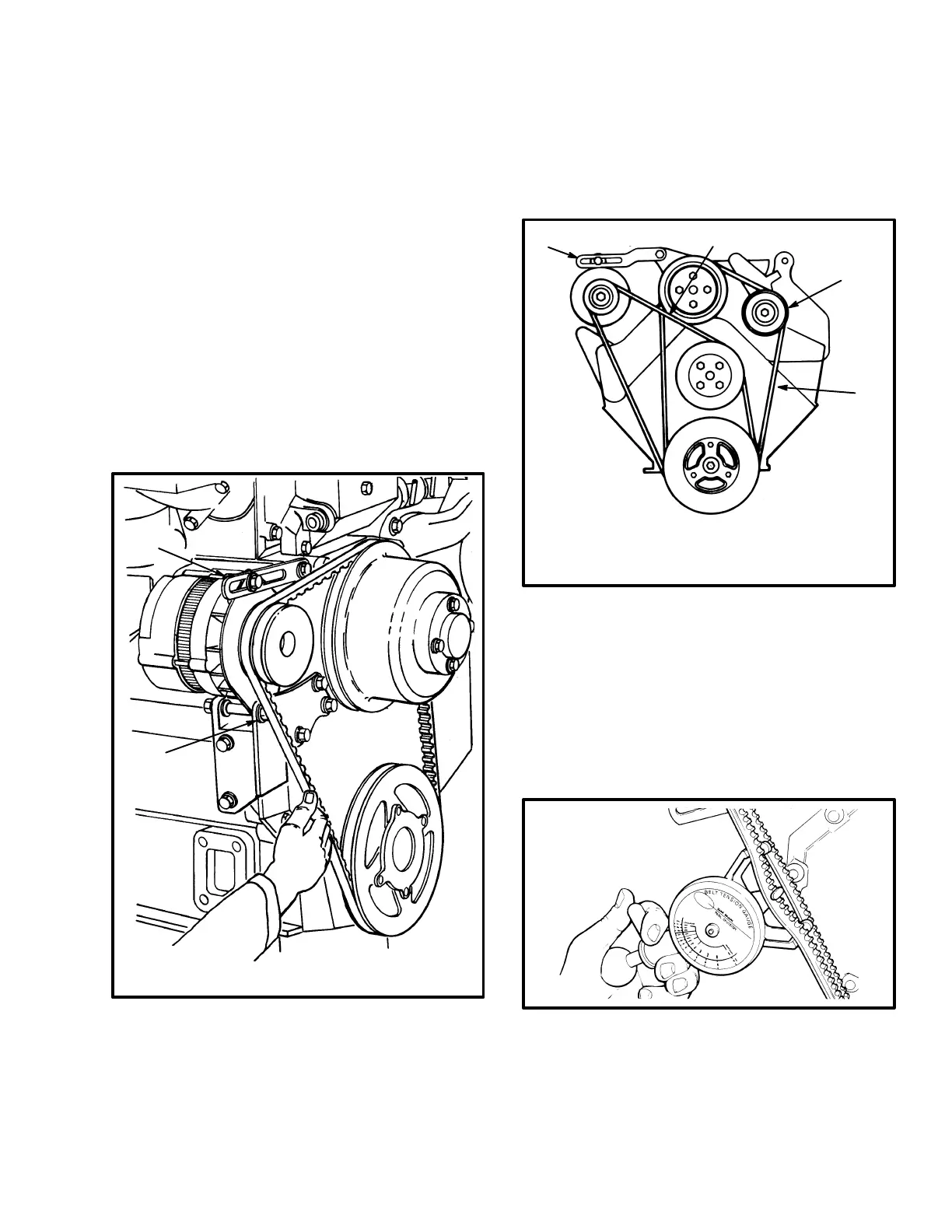

Perkins Diesel Engine

See FIGURE 21. Loosen the bolt on the adjustment link

(2) and the pivot fasteners (1) to adjust the tension of the

drive belts. Push the alternator pulley against the drive

belts to adjust the tension. Tighten the adjustment link

and pivot fasteners.

1. PIVOT FASTENER

2. ADJUSTMENT LINK

12593

1

2

FIGURE 21. CHECK AND ADJUST DRIVE BELT

TENSION (PERKINS DIESEL)

The drive belts are removed from the engine by loosen-

ing the tension and then removing them from the pul-

leys.

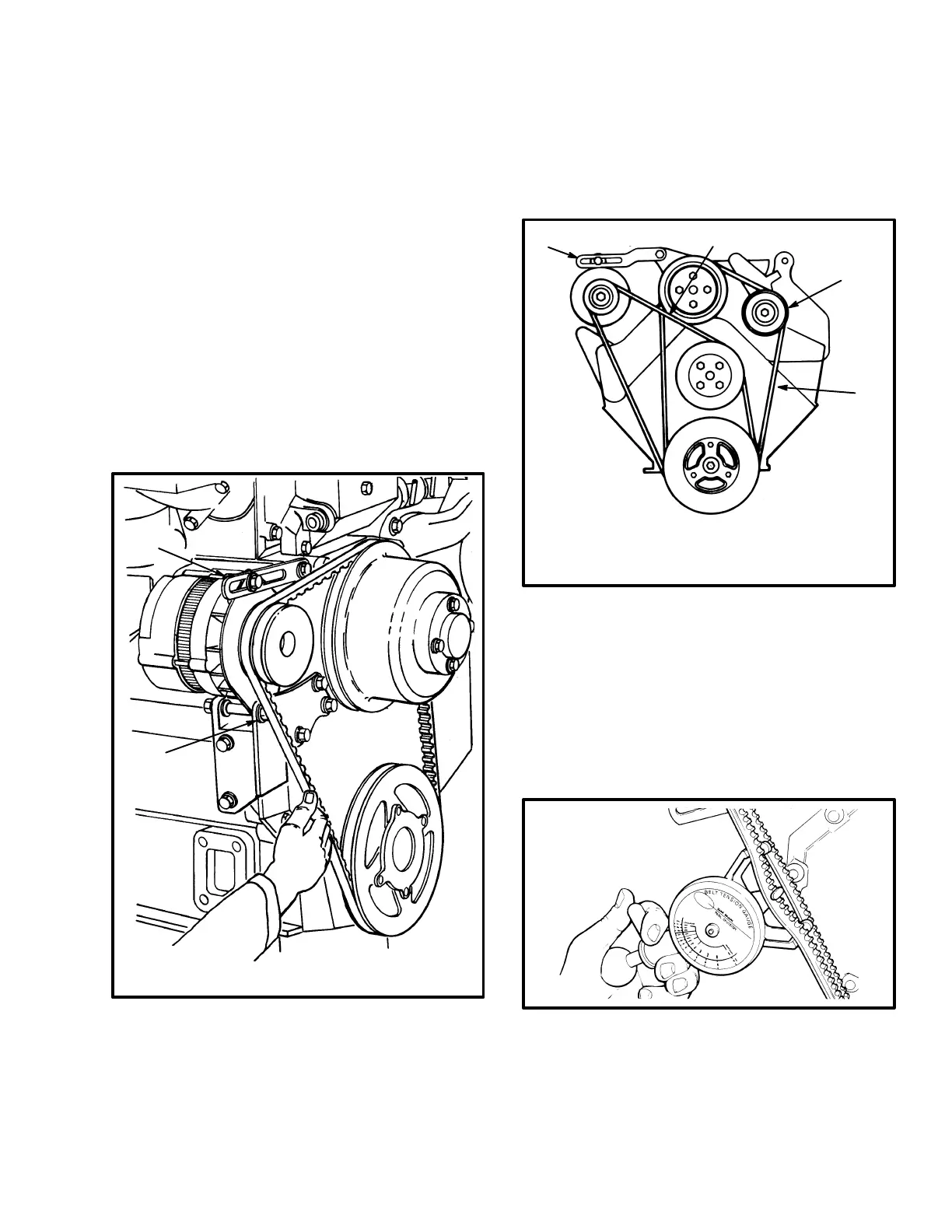

GM V–6 Engine (Early Models)

(See FIGURE 22.)

Drive belt for the coolant pump and alternator.

Loosen the alternator support bracket to adjust the ten-

sion of the belt.

FIGURE 22. DRIVE BELTS (GM V–6)

1. CHECK TENSION HERE

2. ALTERNATOR SUPPORT BRACKET

3. IDLER PULLEY

12201

1

1

2

3

EARLY MODELS

SHOWN

Drive belt for the fan. Loosen the mount for the idler

pulley to adjust the tension of the belt.

A gauge is available that will indicate the tension in the

drive belt. Fit the gauge at the center of the longest

length of the drive belt and measure the tension. See

FIGURE 23. The correct tension is approximately 355

N (80 lbf)

FIGURE 23. GAUGE TO CHECK DRIVE BELT

TENSION

Many service people press on the drive belt with their

thumb at the center of the longest length of the drive belt

and check the deflection. When the thumb pressure is

Loading...

Loading...