Exhaust venting installation

Exhaust venting must slope down towards the boiler with a pitch of at least ¼" per foot (PPs

vent: follow PPs manufacturer requirements for slope), so condensate runs back towards the

trap. Support should be provided for intake and vent piping where it passes through unheated

spaces or underground, with appropriate pipe insulation to prevent freezing of condensates.

Certain installations of the SLmodels can employ 2"vent options. We caution installers when

using horizontal runs of 2"pipe. Air friction from the fast moving exhaust during long burner

runs at high-fire in a 2"pipe can overcome gravity on ¼"per foot vent slope, leaving a pool of

condensate at the next upturned elbow. Pooling can impair the achievement of full high-fire

rating plate performance.

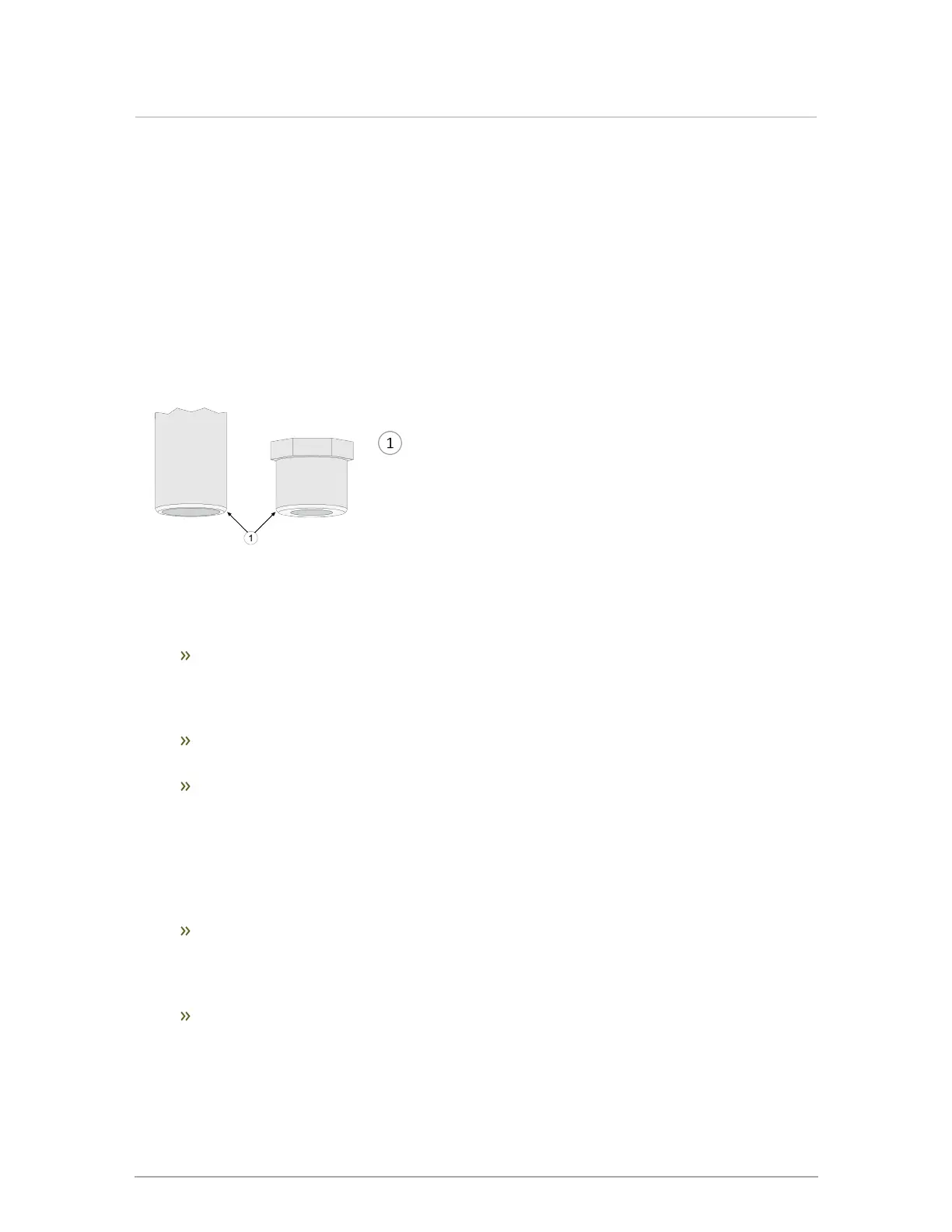

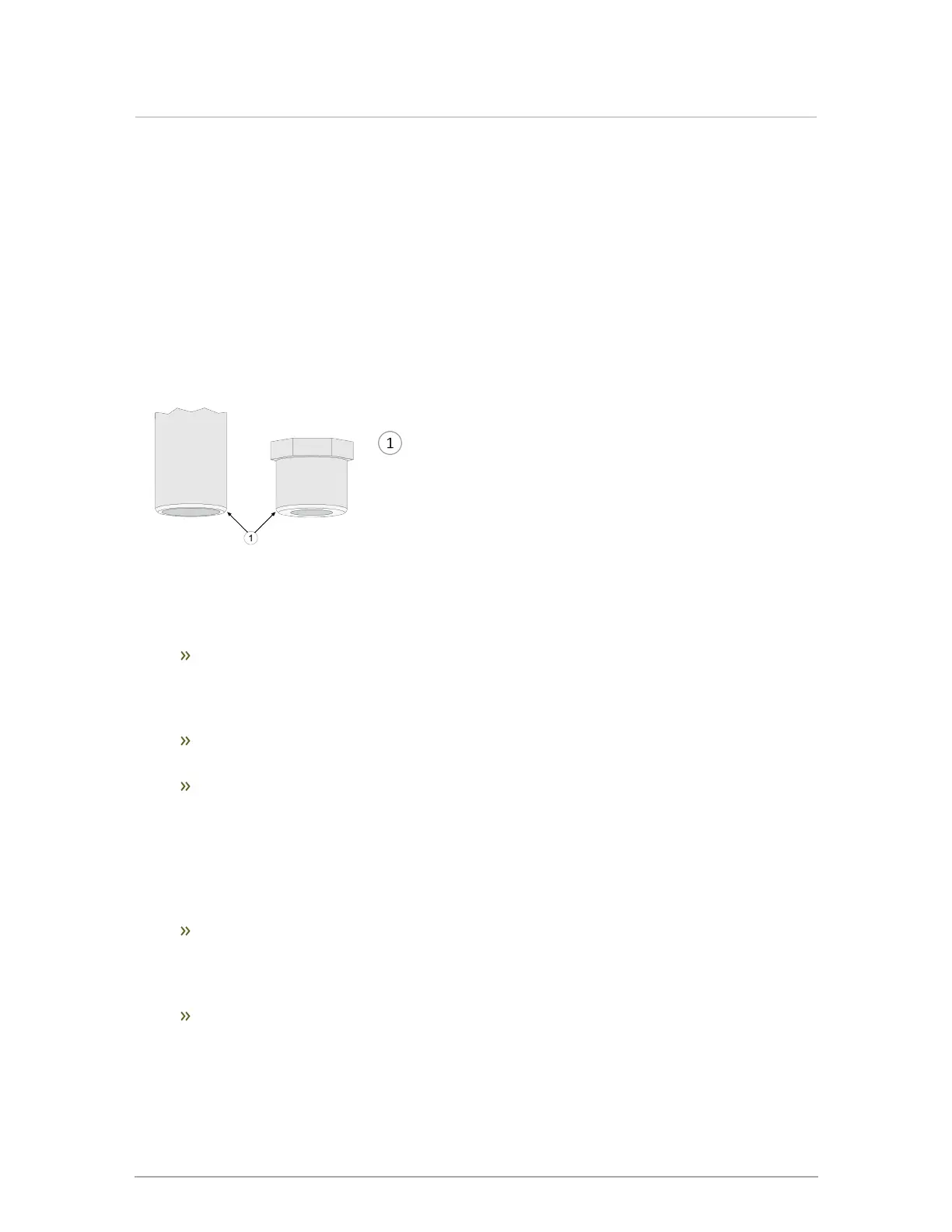

Ensure pipe and fittings are beveled for trouble-free

insertion through exhaust and intake pipe gaskets. Wet

gaskets and pipe before insertion.

Figure 15 Pipe and fitting beveling

Exhaust piping is inserted directly into the left connector on the top of the boiler, then runs

horizontally or vertically to the outdoors. Screen material can be placed at the outlet as

appropriate for the environment (e.g., insects, dust).

Check that material meets local codes including fire stopping requirements. Some local

jurisdictions require a minimum initial length of pipe be exposed or accessible for

inspection. Pipe clearances - no IBC requirements; follow local codes. All piping must

be liquid and pressure tight.

Ensure all venting components are clear of burrs/debris prior to assembly. Clear plastic

debris left in the combustion air piping to avoid intake into the fan.

Secure joints using appropriate solvent cement to bond the respective pipe material

(Canada: CPVC cement approved under ULC-S636, in accordance with its

manufacturer instructions; USA: PVC (ASTM D2564), or PVC/ABS (D2235) - Use

transition glue anywhere that PVC and CPVC are joined. Follow the cement

manufacturer’s instructions closely when joining various components. For PPs,

connections shall be secured using approved retainer clips supplied by the respective

PPs manufacturer.

Check that vent connections are liquid and pressure tight. Prior to firing the boiler, and

before any of the venting run is concealed by the building construction, test the exhaust

joints under fan pressure with the vent blocked, using a soap and water solution. The

installer must fill the condensate trap prior to testing.

Coat all joints with an approved leak test solution just as you would joints in a gas line,

and make sure that there are no leaks. We suggest attaching a tag on the vent line near

the condensate drain tee with the type of test, the date and the installer’s name.

Loading...

Loading...