1-23

INSTALLATION

VFC 15-150 - VFC 45-225 MODULATING GAS BOILERS

shallbecarriedoutaftertheretrot,withlterclearingafterthe1stday,1stweek,

monthandannuallythereafter.Careistobetakentoavoiduseofferrousttings

and pumps on PB tube systems.

1.6.2 Installation Rules

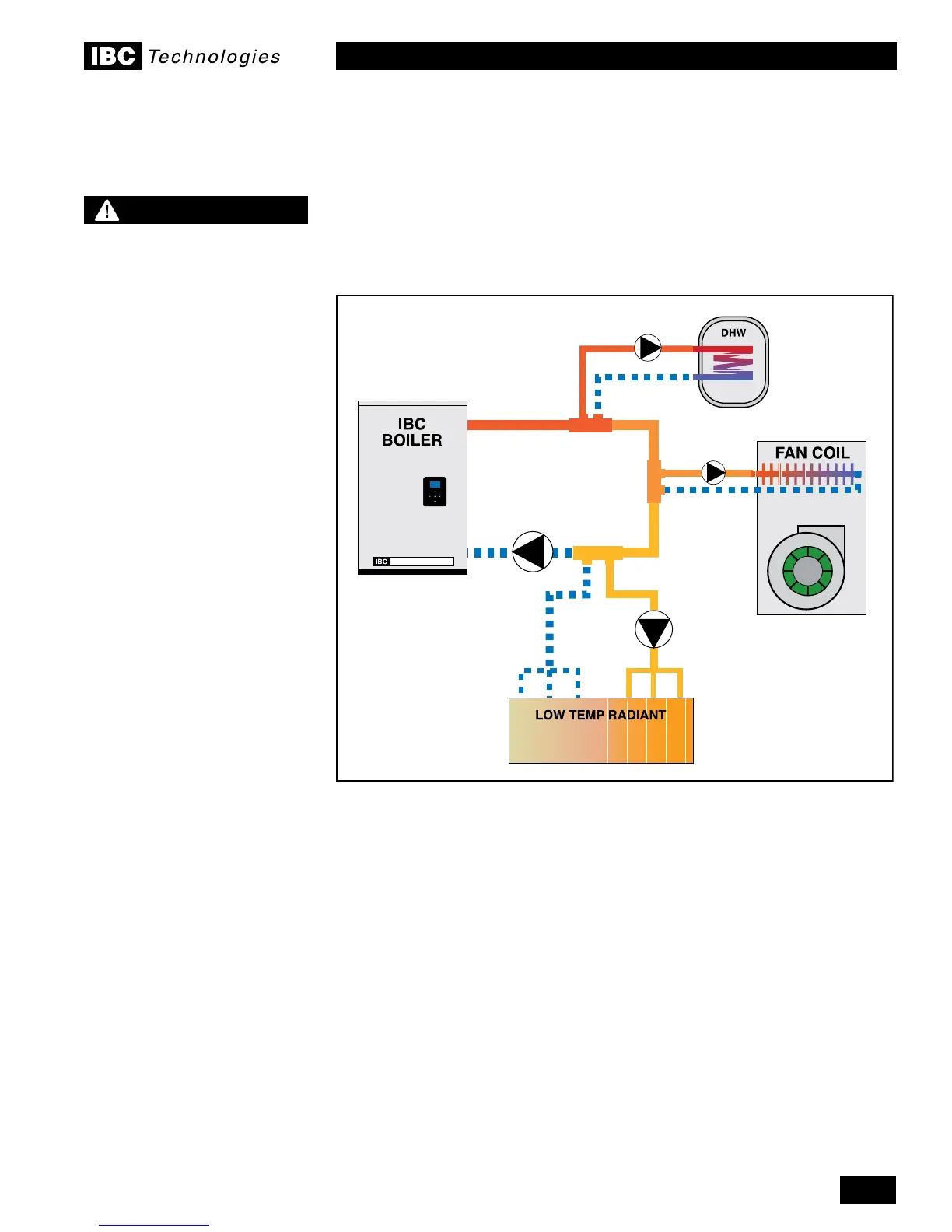

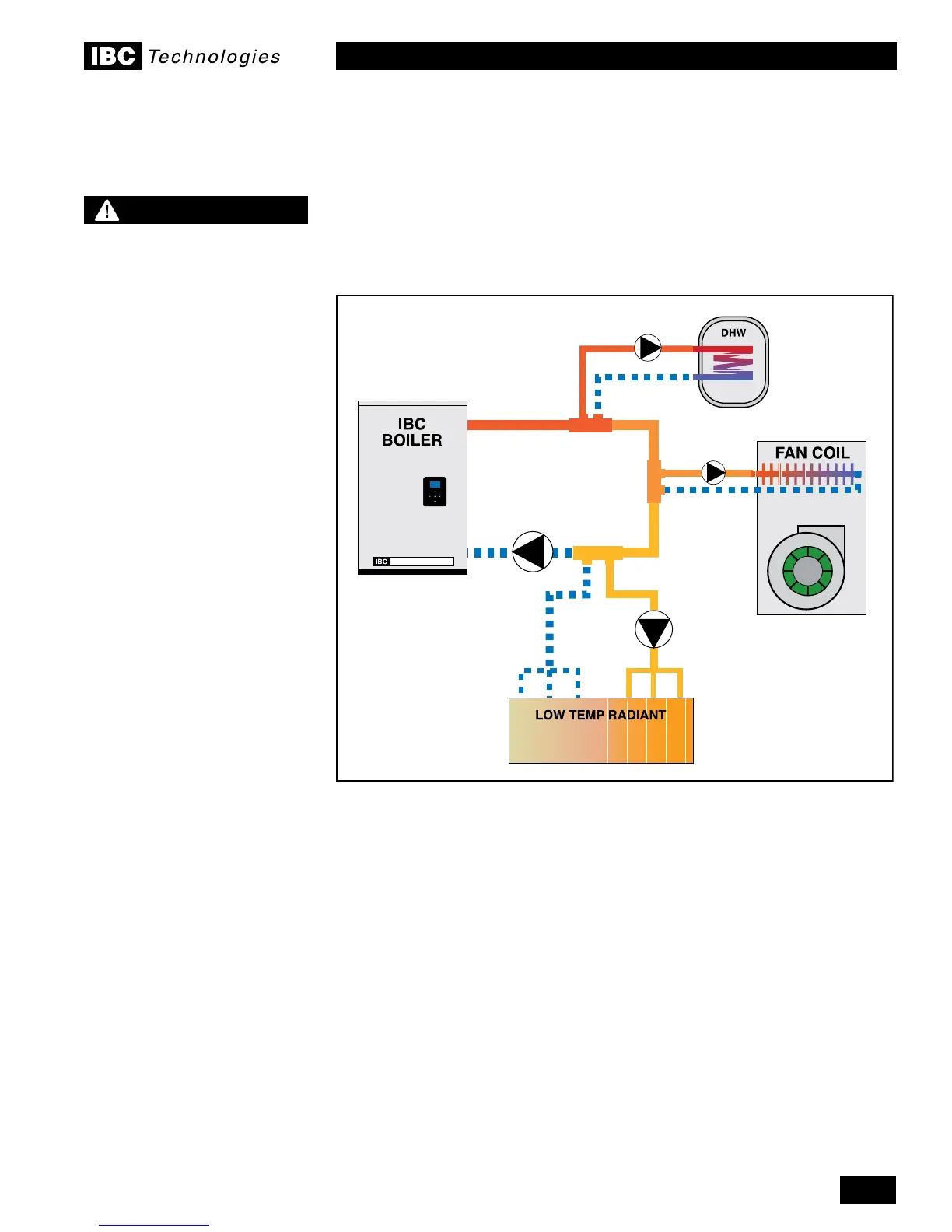

NOTE: The Boiler Trim element – common to each of the following systems

-includesthepressurerelief,ll,expansiontankandairbleedelements.The

primary pump can be located on either the Supply or Return piping sections.

Features of the preferred Primary / Secondary piping system:

1. Goodcirculatingwaterowthroughtheboilerirrespectiveofloadorradiation

system head

2. AllowsexibleΔT°controlinsecondaryloops

3. Adds to the system’s thermal buffering, to assist in handling small loads and

temperature transition.

Thispipingcongurationrequiresanextrapump.TheVFCmodulatingseries

boilers’ controller hosts wiring terminals and integral relays to simplify installation

and operation of this preferred layout, offsetting such costs.

For optimal performance, place pumps on the supply side of secondary loops

to facilitate air evacuation. Use pumps with internal check valves to avoid ghost

owsandthermalsiphoning.

The primary loop temperature may need to transition from a 180°F domestic water

heatingloadtoa100°Fradiantoorrequirement.Thesecondarypumpswillswap

off/on simultaneously, provided the pre-set maximum allowable temperature of the

Figure 26: Basic Primary/Secondary, 3 load piping concept

NOTE

This piping drawings in this

manual are simple schematic

guides to a successful

installation. There are many

necessary components not

shown, and details such as

thermal traps are left out so

the drawings have greater

clarity. We require that

our boilers be installed by

licensed and experienced

trades people who are familiar

with the applicable local

and national codes. System

design is to be completed

by an experienced hydronic

designer or Engineer. It is

necessary to carefully read

and follow these installation

instructions along with the

application drawing that ts

your system.

Loading...

Loading...