DuringtheHard Startmode,fullvoltageisappliedtothemotorduringstartuptoovercomewindmillingandtolubricatethebearings.

Thepositionofthehardstartdialdeterminesthetimeperiodofthehardstartmode.Thedialcanbeadjustedbetween0.2secondsandapproximately4seconds.

Setthehardstartdialaccordingtothetypeofmotoryouhave.Ifyouhaveaball bearing motor,setthehardstartdialtotheMINposition.Ifyouhaveasleeve bearing motor,setthe

hardstartdialtothemiddleofthesleevebearingrange.

Afteryoubeginattherecommendedsetting,youcannetunethehardstarttimewithintherecommendedrangeforthetypeofmotoryouhave.

Itisrecommendedthatyouusetheminimumpossiblehardstarttimetoavoidblowingtoomuchcoldairoverthecondenser.

Thehardstartmodeappliesfullvoltagetothemotorforthesettimeperiod.Afterwards,themotorspeedisdictatedbythetemperaturesensor(s).

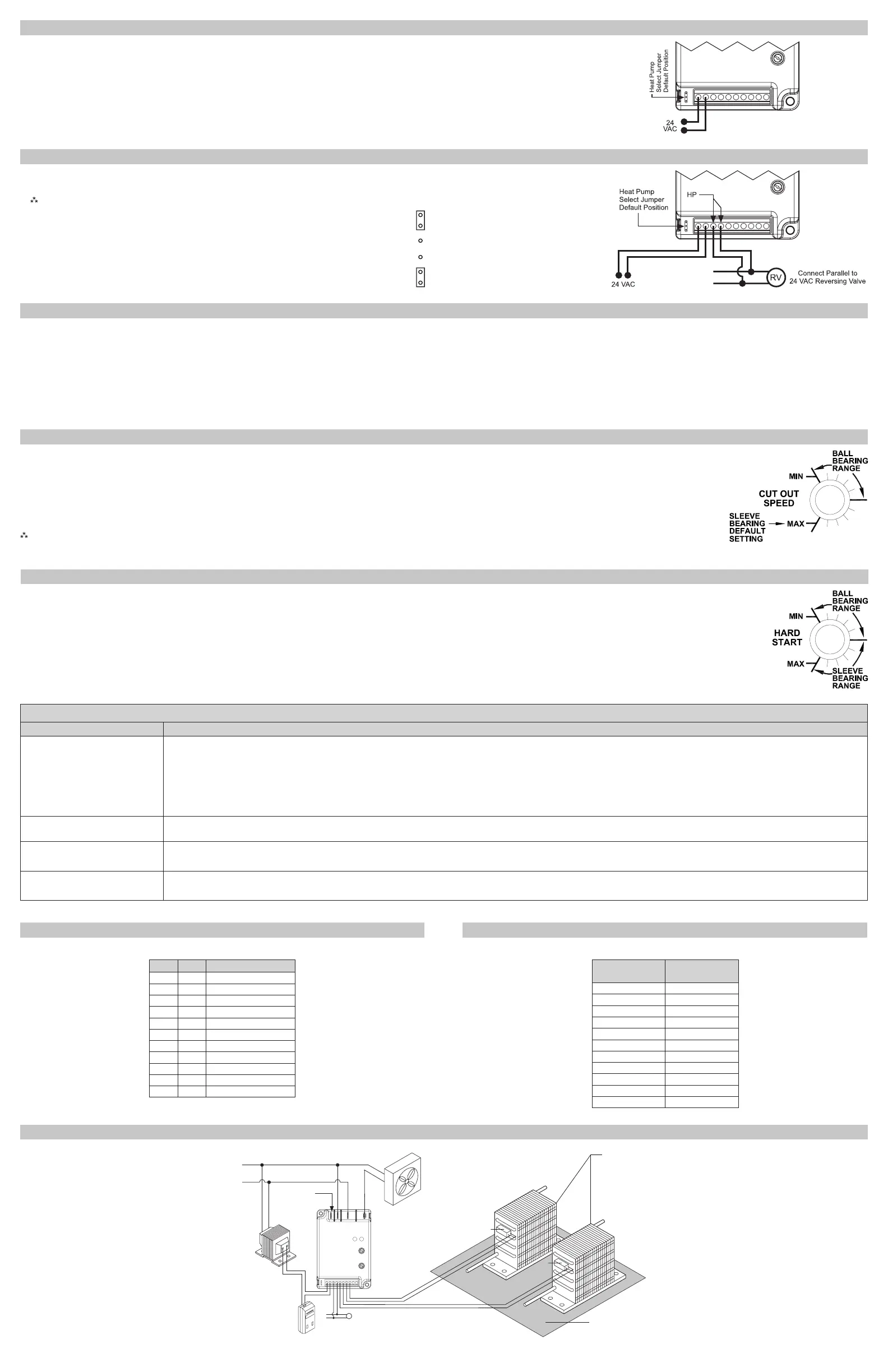

Setting the Hard Start Speed

Thecutoutspeeddialadjuststhemotorvoltagerange.Setthecutoutvoltagedialaccordingtothetypeofmotoryouhave.

Sleeve Bearing Motors: Setthecutoutspeeddialtothemiddleofthesleevebearingrange.Inthisrange,themotorcanrundownapproximately40-50%of

thefulllinevoltage,whichallowssufcientRPMsforcoolingandlubrication.

CAUTION!:

Withsleevebearingmotors,itisimportantnottoadjustoutsidethesleevebearingrangeorbearingfailuremayresult.

Ball Bearing Motors:SetthecutoutspeeddialtotheMINpositionintheballbearingrange.Thispositionoffersthegreatestrangeofspeedcontrol.Atthe

MINsettingthemotorcanrundowntoapproximately20-30%ofthefulllinevoltage.

Note:Afterstartingattherecommendedsettingsforeithersleeveorballbearingmotors,youcannetunethecutoutspeedtoachievethedesiredresults.

Setting the Cutout Speed

Mode of Operations

Whenusingtemperatureprobes,thecontrolwillmaintaincondensertemperaturebetween7°Faboveand7°FbelowdialedTemperatureSetpoint.ThedialTemperatureSetpointrangeis70°Fto140°F

Whenusingpressureprobes,thecontrolwillmaintaincondenserpressurebetween20psigaboveand20psigbelowdialedPressureSetpoint.ThedialPressureSetpointrangeis35psigto465psig.

Theisnocorrelationbetweendialtemperatureandpressurescalesonthecontrol

Whenthemotorstartsrunningitwillhardstartforthelengthoftimedictatedbythehardstartdialsetting.Afterthehardstarttimehaselapsed,themotorspeediscontrolledbytheprobereading,temperatureor

pressure.Thegreenlightturnsonwhenthemotorrunsatfullspeed.

Asthesensedtemperature/pressuredecreases,theoutputvoltagedecreases.Theyellowlightturnsonduringmotorvariablespeed.Theoutputvoltagemaydecreasetothedeterminedcutoutspeeddictatedby

thecutoutspeeddial.Uponreachingthecutoutspeedsetting,theoutputvoltagegoestozerovolts.Theyellowlightturnsoff.

Appendix BAppendix A

°C °F Resistance (KΩ)

0° 32° 32.7

5° 41° 25.4

10° 50° 19.9

15° 59° 15.7

20° 68° 12.5

25° 77° 10.0

30° 86° 8.1

35° 95° 6.5

40° 104° 5.3

45° 113° 4.4

50° 122° 3.6

Pressure

(psig)

Voltage

(Vdc)

0 0.5

50 0.9

100 1.3

150 1.7

200 2.1

250 2.5

300 2.9

350 3.3

400 3.7

450 4.1

500 4.5

Temperature vs. Probe Resistance Pressure vs. Voltage

1.TheHeat Pumpterminalsacceptthe24VACsignalfromthereversingvalveholdingcoil.Makeaparallel

connectionfromthereversingvalvetotheHPterminals.

Note:Do not apply a voltage higher than 30 VAC to the HP terminals.

2.IftheHeat PumpisintheHeatingmodeandthereversingvalveisenergized,then

theHeat Pump SelectjumpermustbeintheDefault(N.O.)position.

3.IftheHeat PumpisintheHeatingmodeandthereversingvalveisnotenergized,

thentheHeat Pump SelectjumpermustbeintheN.C.position.

N.O.

N.C.

Connections for Heat Pump Systems

Troubleshooting

Symptom Problem

Unitfailstostart UsinganACvoltmeter,measurethevoltagebetweenthe24VACterminals.Itshouldreadapproximately24volts.MeasurethelinevoltagebetweenLINE1andLINE2to

conrmthatlinevoltageispresent.

Iflightsareashingalternativelythennoprobeisconnectedormalfunctionprobe.

Whenusingatemperatureprobe,disconnectitanduseanohmmetertomeasuretheresistancebetweenthewires.ItshouldmatchthechartinAppendixA.

Whenusingapressureprobe,withpowerappliedtothecontroluseavoltmetertomeasurevoltsDCbetweenCOMMandP1orP2,wherethewireisconnected.Thereading

shouldbeaccordingtothechartinAppendixB.

Thefuseisblownand/orsignsof

damageontheunit

Theunithasbeenmiswiredandmaybepermanentlydamaged.

ThefancyclesfromONtoOFF

withlittleornospeedmodulation

Reducehard startstettingtominimumneededtoacceleratethefan.Excessivehardstartcauseslargepressuredropsbyrunningtoomuchcoldairoverthecondenser.

Shouldthecyclingpersist,relocatethetemperatureprobeupthecondensertoincreasesensitivitytotemperaturechangeand/oradjustthetemperaturesetpoint.

Thehighpressureswitchtripsoff SeeUnitfailstostartabove

Checkthesetpointandreduceitifneeded

1.For non-heat pump applications,theheatpumpselectjumpermustbeintheDefault(N.O.)position,andtheHPterminalsmustbeleftunconnected.

2.SettheCutoutSpeedandtheHardStartTimetotheappropriatepositionsforthetypeofmotoryouhave(seebelow).

Connections for Air Conditioning Only

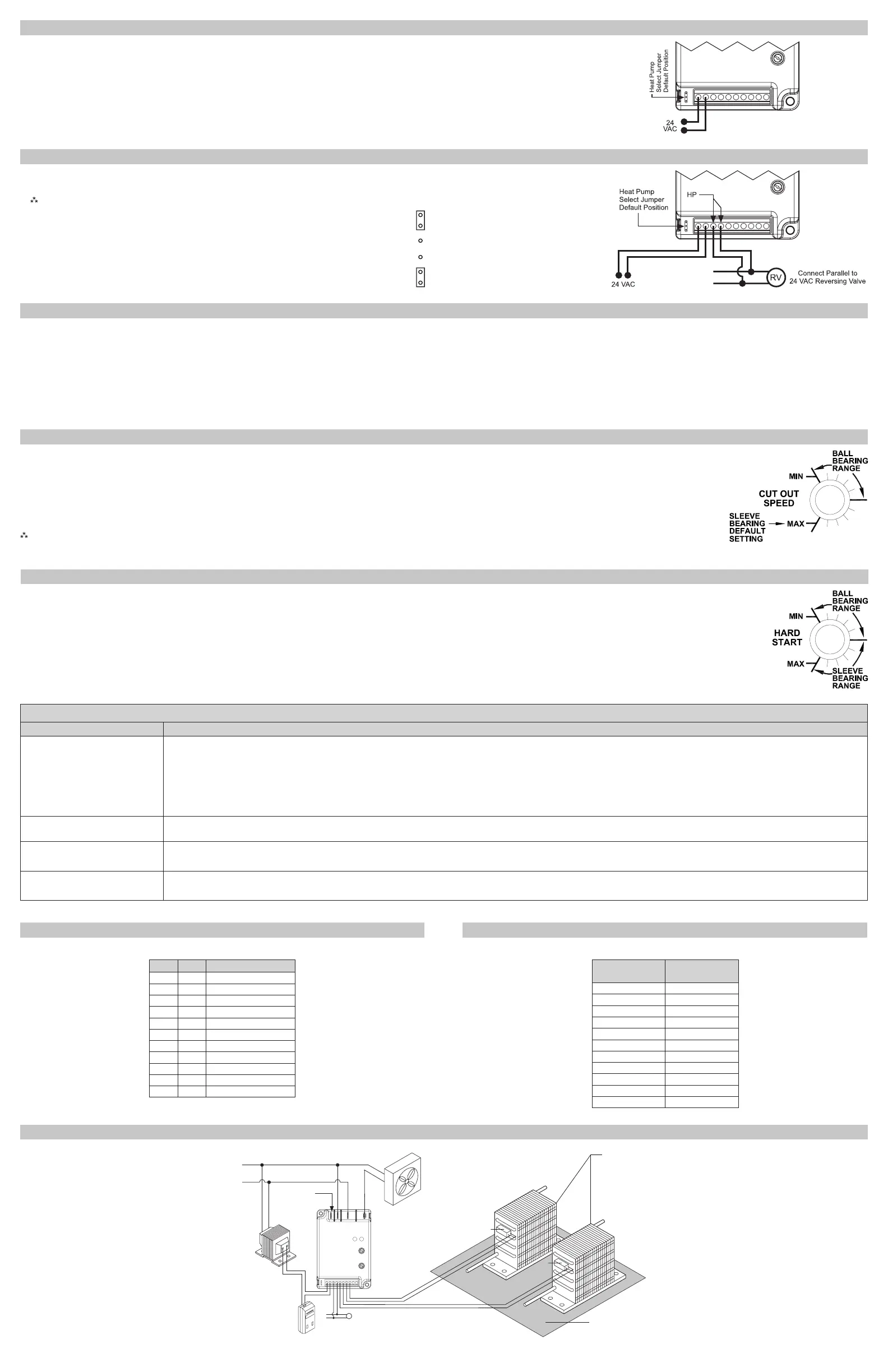

ICM333 Typical Installation

Condenser

Sensor

Sensor

Sensor

ICM333

canmonitor

twocondensers

Motor

1

Motor

2

ReversingValvefor

HeatPump

T-Stat

Control

Transformer

Line2

LineVoltage

Terminalto

beusedfor

480/600VAC

Line1

Loading...

Loading...