13

VF1

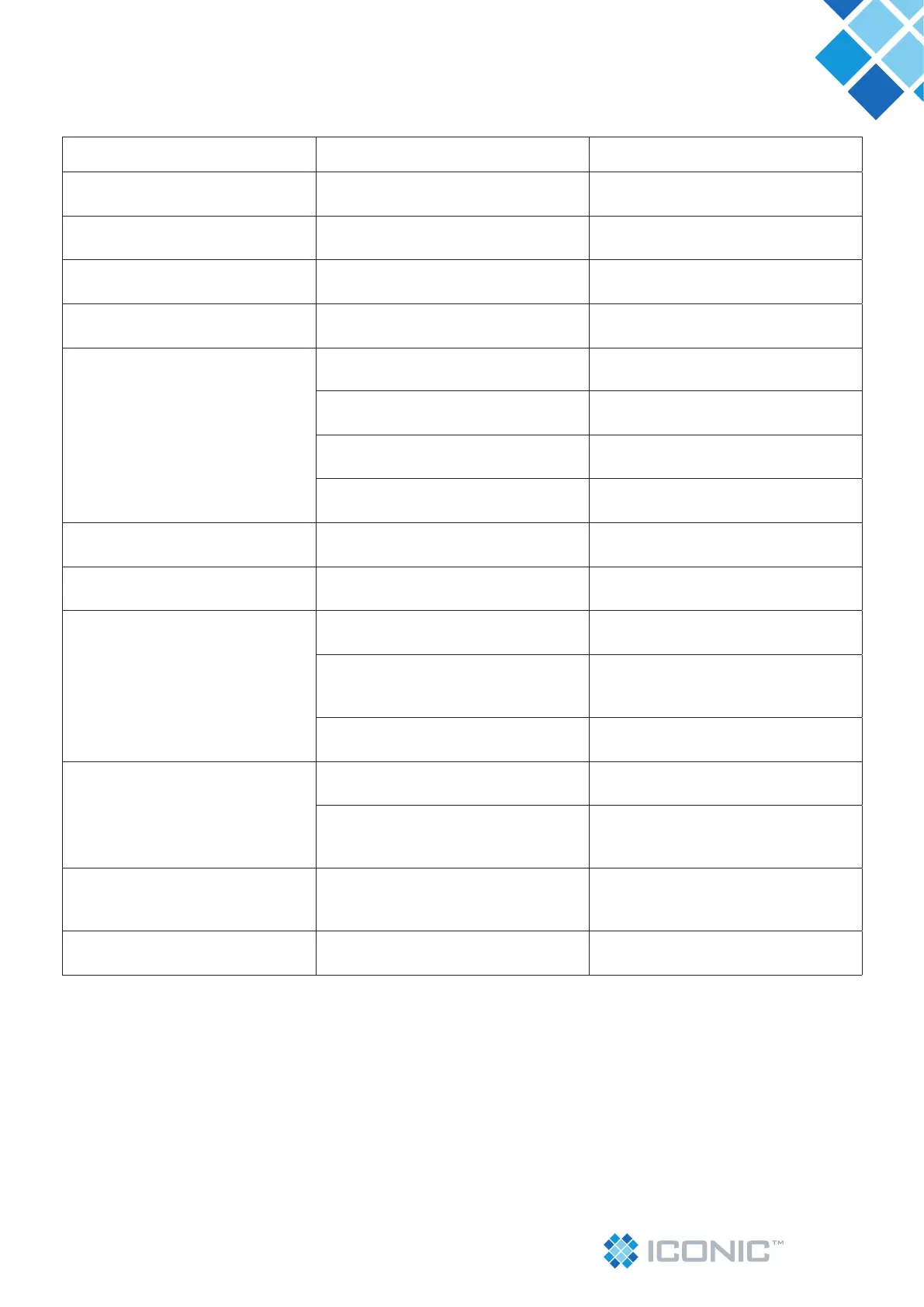

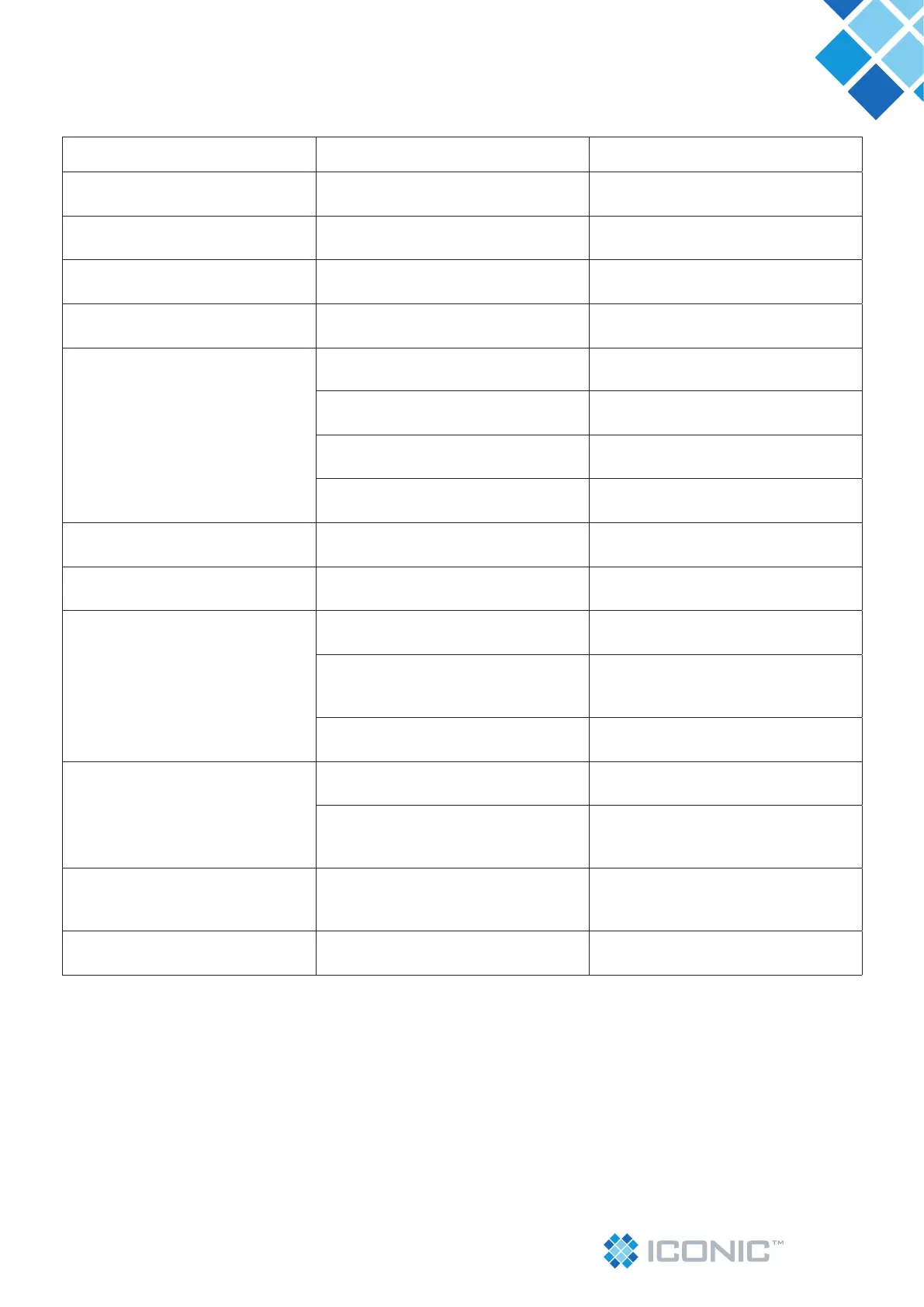

9 - TROUBLESHOOTING

Problem Likely cause Solution

The equipment won’t start, general

switch is off.

Machine is powerless.

General switch starts but heating does

not work.

Heating element is burnt. (22). Replace the heating element, call the

Authorized Service.

Heating is normal but motor does not

start.

End-of-course pin (32) with some

imperfection.

Replace or adjust the end-of•course pin

(32).

General switch starts, but heating and

motor don’t.

Internal wiring has problems. Call the Authorized Service.

Weak suction, insufcient vacuum

forming or without dened contour.

Check that the vacuum chamber holes

are free.

Clean holes with 1mm Ø metallic pin.

Verify the type of plaster. Do not use resined plaster.

High model Use the model holder on the cup side or

cut the model away.

Cup type model holder (7) damaged. Replace the model holder (07).

Rotary movement of the plate xation

unit is locked.

Rotary lock screw is tight (Photo 20). Loosen the screw with the Allen wrench

supplied with the equipment (Photo 20).

Rotary movement of the plate xation

unit does not stop at end of course.

Rotary pin (29) misadjusted. Adjust the pin (29) by the screw (27), guide

by the exploded drawing.

Vertical movement on the column of the

plate xation unit is very hard.

Right cable of vacuum actuation (03) tight Loosen the handle half way in a counter-

clockwise direction.

Residues or dirt in upright Turn off the machine and clean the column

with dry cloth by doing vertical movements

with the blank xation unit.

Machine overheated causing excessive

expansion of the sliding elements.

Wait 30 minutes until the machine cools

down and resume work.

Motor cabinet (01) too hot. Machine operating too long Wait 30 minutes until the machine cools

down and resume work.

Motor ventilation blocked Verify if in the space between the support

base and the cabinet bottom there is no

obstruction.

The blank gets loose from the xing unit

at the plasticization.

Insufcient tightening of the blank by the

lock ring (11).

Tighten a little bit more and check the

blank thickness, the machine accepts

blanks of up to 6mm thick.

Plate xation unit will not lock out under

heating unit.

Plastic resistance bung is missing. Undo right side handle (white dot). Replace

missing plastic resistance bung.

Loading...

Loading...