Use a flat blade screwdriver and tap on the knockout on

opposite sides, where the knockout meets the casing. Fold the

knockout down with duct pliers and work the knockout back

and forth until it is removed. Trim any excess metal from the

knockout with tin snips.

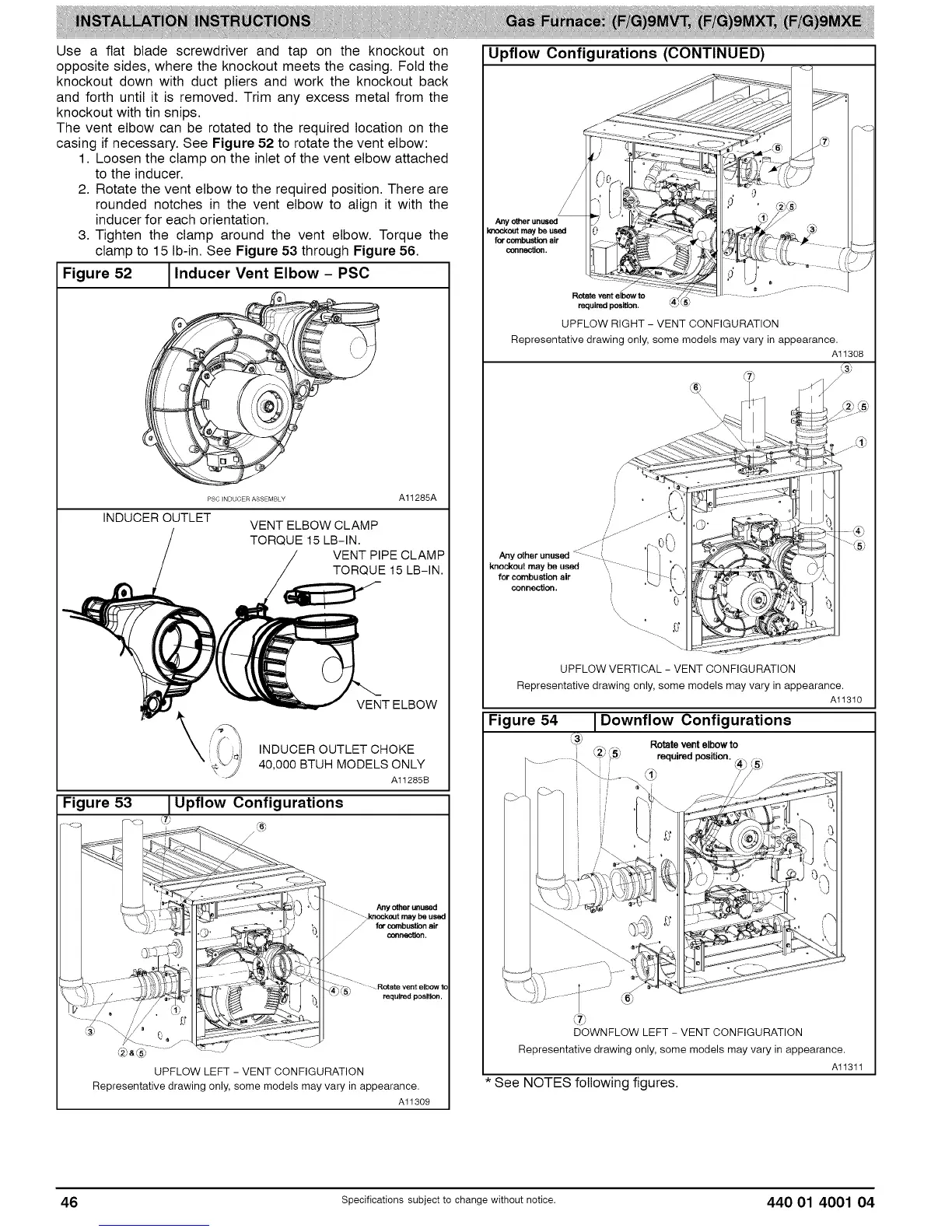

The vent elbow can be rotated to the required location on the

casing if necessary. See Figure 52 to rotate the vent elbow:

1. Loosen the clamp on the inlet of the vent elbow attached

to the inducer.

2. Rotate the vent elbow to the required position. There are

rounded notches in the vent elbow to align it with the

inducer for each orientation.

3. Tighten the clamp around the vent elbow. Torque the

clamp to 15 Ib-in. See Figure 53 through Figure 56.

Figure 52 I Inducer Vent Elbow - PSC

1

PSC INDUCER ASSEMBLY A11285A

INDUCER OUTLET

VENT ELBOW CLAMP

TORQUE 15 LB-IN.

VENT PIPE CLAMP

TORQUE 15 LB-IN.

Figure 53

\

VENT ELBOW

INDUCER OUTLET CHOKE

40,000 BTUH MODELSONLY

A11285B

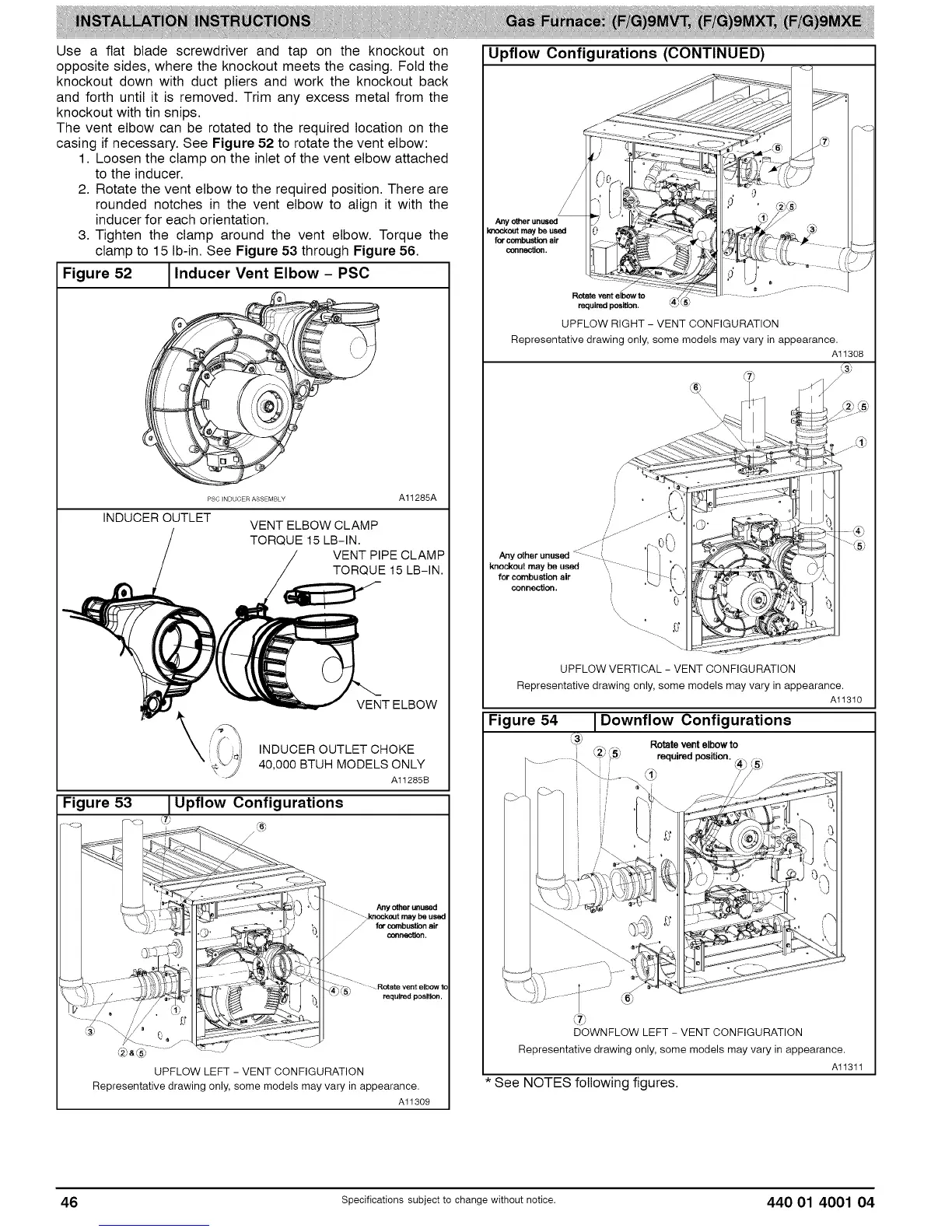

Upflow Configurations

Any _ _'tused

for co_bustion air

o_nectten.

" - Rotate vent elbOW to

required position.

d2b_®

UPFLOW LEFT - VENT CONFIGURATION

Representative drawing only, some models may vary in appearance.

Al1309

Upflow Configurations (CONTINUED)

f/ ......

/ <[1=,; . o ......

=ot .........{

requim_l posi_on. _t:}'

UPFLOW RIGHT - VENT CONFIGURATION

Representative drawing only, some models may vary in appearance.

Alt308

_. (s)

_t m=ybe.=_ '., L / k_ ¢%

for combustion air ".... [ } {- ' _,_:_ _ ":_I"\

UPFLOW VERTICAL - VENT CONFIGURATION

Representative drawing only, some models may vary in appearancAi i310

Figure 54 Downflow Configurations

* See NOTES following figures.

Alt3tt

46 Specifications subject to change without notice. 440 01 4001 04

Loading...

Loading...