8. Reassemble all parts in reverse order as removed. Be sure to

engage the main burner orifices in the proper opening in the

burners.

9. After reassembling, turn gas on and check all joints for gas

leaks using a soapy solution. All leaks must be repaired im-

mediately.

Gas PipingRequirements

1. Install gas piping in accordance with local codes, or in the ab-

sence of local codes, the applicable national codes.

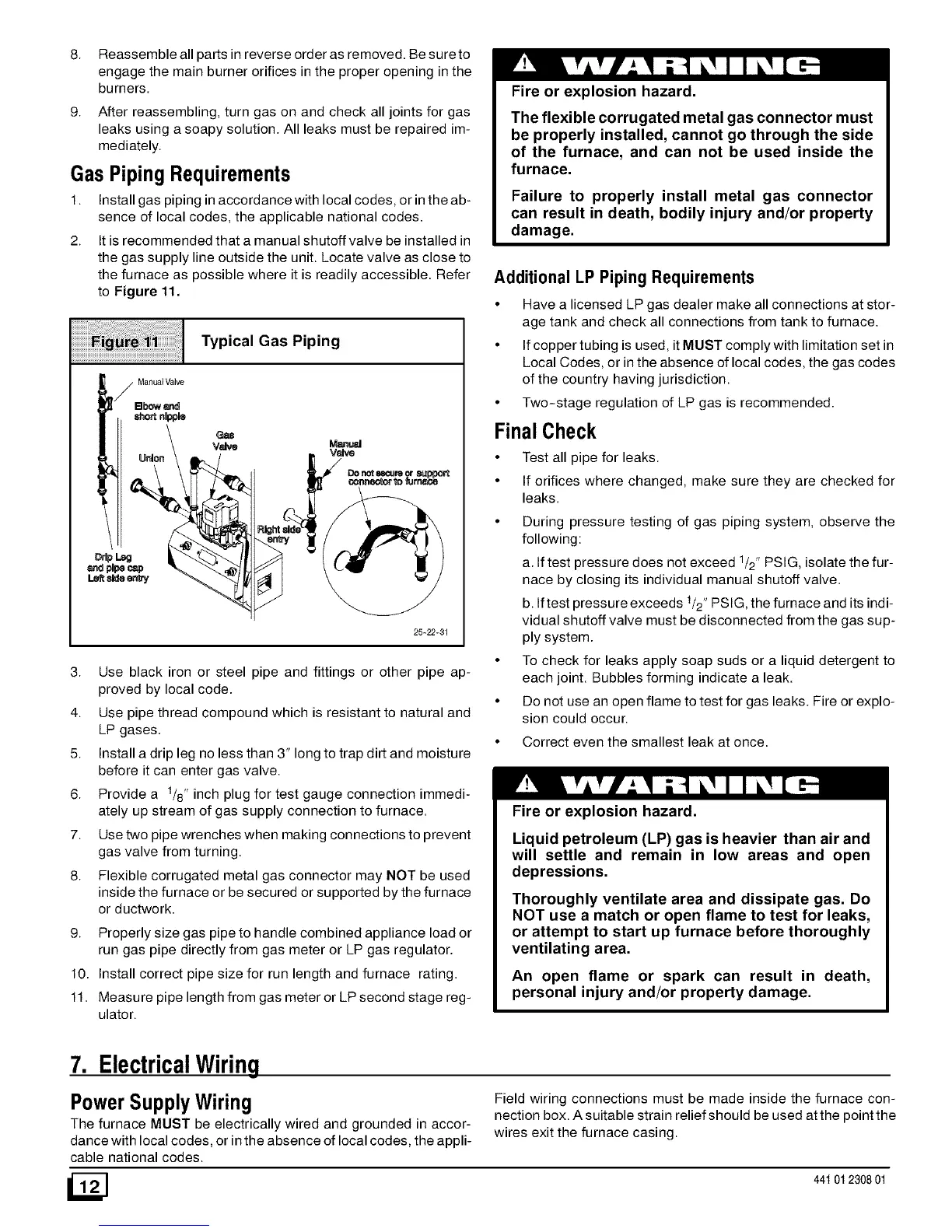

2. It is recommended that a manual shutoff valve be installed in

the gas supply line outside the unit. Locate valve as close to

the furnace as possible where it is readily accessible. Refer

to Figure 11.

ManuatValve

Bbow end

sh_ nipple

Typical Gas Piping

25-22-31

3. Use black iron or steel pipe and fittings or other pipe ap-

proved by local code.

4. Use pipe thread compound which is resistant to natural and

LP gases.

5. Install a drip leg no less than 3" long to trap dirt and moisture

before it can enter gas valve.

6. Provide a 1/8" inch plug for test gauge connection immedi-

ately up stream of gas supply connection to furnace.

7. Use two pipe wrenches when making connections to prevent

gas valve from turning.

8. Flexible corrugated metal gas connector may NOT be used

inside the furnace or be secured or supported by the furnace

or ductwork.

9. Properly size gas pipe to handle combined appliance load or

run gas pipe directly from gas meter or LP gas regulator.

10. Install correct pipe size for run length and furnace rating.

11. Measure pipe length from gas meter or LP second stage reg-

ulator.

Fire or explosion hazard.

The flexible corrugated metal gas connector must

be properly installed, cannot go through the side

of the furnace, and can not be used inside the

furnace.

Failure to properly install metal gas connector

can result in death, bodily injury and/or property

damage.

Additional LP PipingRequirements

• Have a licensed LP gas dealer make all connections at stor-

age tank and check all connections from tank to furnace.

• If copper tubing is used, it MUST comply with limitation set in

Local Codes, or in the absence of local codes, the gas codes

of the country having jurisdiction.

• Two-stage regulation of LP gas is recommended.

FinalCheck

• Test all pipe for leaks.

• If orifices where changed, make sure they are checked for

leaks.

• During pressure testing of gas piping system, observe the

following:

a. If test pressure does not exceed 1/2" PSIG, isolate the fur-

nace by closing its individual manual shutoff valve.

b. If test pressure exceeds 1/2"PSIG, the furnace and its indi-

vidual shutoff valve must be disconnected from the gas sup-

ply system.

• To check for leaks apply soap suds or a liquid detergent to

each joint. Bubbles forming indicate a leak.

• Do not use an open flame to test for gas leaks. Fire or explo-

sion could occur.

• Correct even the smallest leak at once.

Fire or explosion hazard.

Liquid petroleum (LP) gas is heavier than air and

will settle and remain in low areas and open

depressions.

Thoroughly ventilate area and dissipate gas. Do

NOT use a match or open flame to test for leaks,

or attempt to start up furnace before thoroughly

ventilating area.

An open flame or spark can result in death,

personal injury and/or property damage.

7. ElectricalWiring

PowerSupplyWiring Field wiring connections must be made inside the furnace con-

The furnace MUST be electrically wired and grounded in accor- nection box. A suitable strain relief should be used at the point the

dance with local codes, or in the absence of local codes, the appli- wires exit the furnace casing.

cable national codes.

44t 01230801

Loading...

Loading...