Without a barometric damper:

Due to the lack of dilution air that would ordinarily be drawn into the

barometric damper, the dew point of the flue gasses is raised. To

offset the increased tendency for vent condensation, the chimney

must be lined. The liner must be insulated according to the insulating

procedure recommended by the manufacturer of the liner. Also, the

vent connector should be as short as possible and either be of double

wa!l construction, or be of single wall construction insulated with 1" of

insulation.

CAUTION

When the furnace (chimney installation) is co-vented

with other combustion appliances such as a water

heater, the allowable venting materials (i.e. L-Vent etc.)

for use with those appliances should also be

investigated.

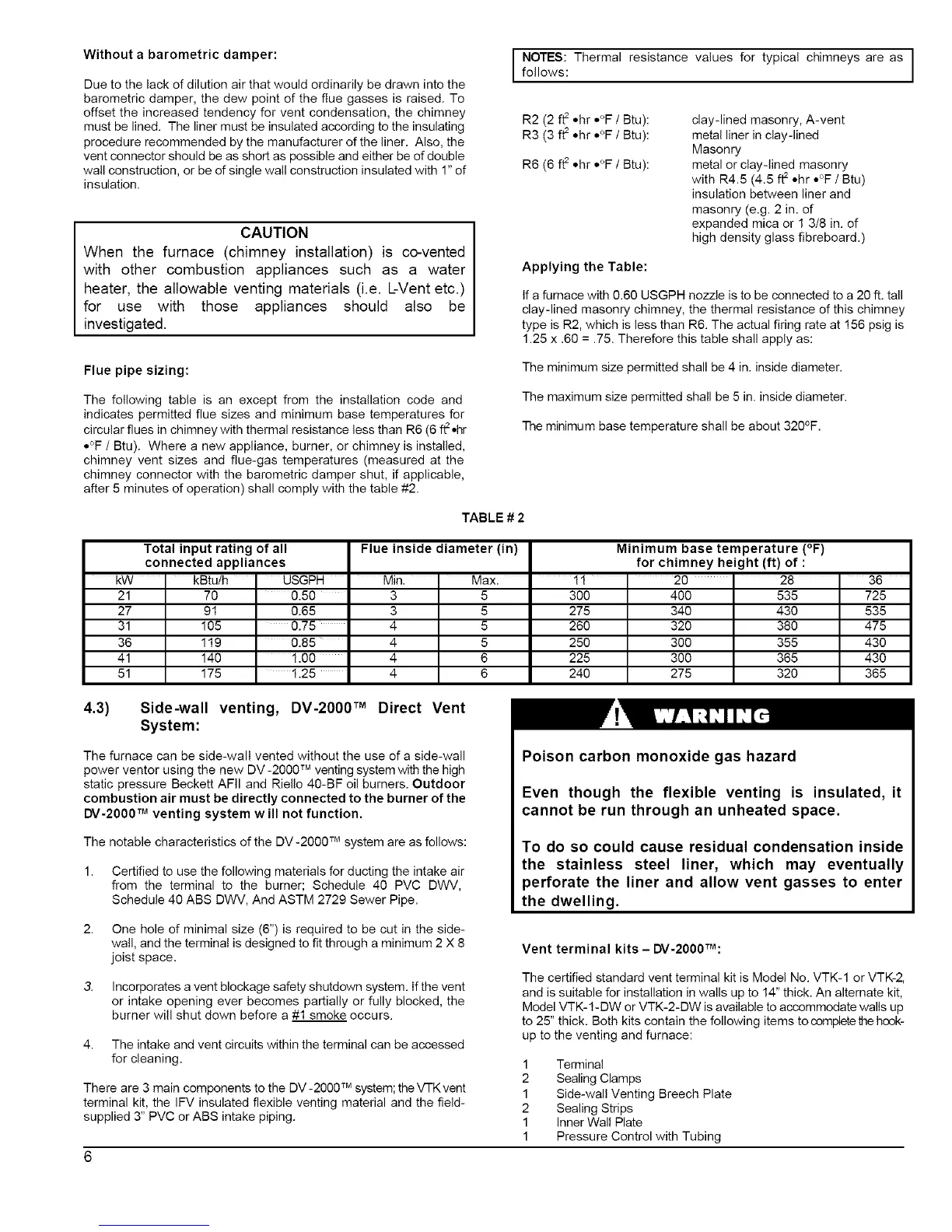

I NOTES: Thermal resistance values for typical chimneys are asfollows:

R2 (2 ft 2 ,hr ,°F / Btu):

R3 (3 ft t ,hr ,°F / Btu):

R6 (6 ft 2 ,hr ,°F / Btu):

clay-lined masonry, A-vent

metal liner in clay-lined

Masonry

metal or clay-lined masonry

with R4.5 (4.5 ft2 *hr *°F / Btu)

insulation between liner and

masonry (e.g. 2 in. of

expanded mica or 1 3/8 in. of

high density glass fibreboard.)

Applying the Table:

If a fumace with 0.60 USGPH nozzle is to be connected to a 20 ft. tall

clay-lined masonry chimney, the thermal resistance of this chimney

type is R2, which is less than R6. The actual firing rate at 156 psig is

1.25 x .60 = .75. Therefore this table shall apply as:

Flue pipe sizing:

The minimum size permitted shall be 4 in. inside diameter.

The following table is an except from the installation code and

indicates permitted flue sizes and minimum base temperatures for

circular flues in chimney with thermal resistance less than R6 (6 ftt*hr

*°F / Btu). Where a new appliance, burner, or chimney is installed,

chimney vent sizes and flue-gas temperatures (measured at the

chimney connector with the barometric damper shut, if applicable,

after 5 minutes of operation) shall comply with the table #2.

The maximum size permitted shall be 5 in. inside diameter.

The minimum base temperature shall be about 320°F.

TABLE # 2

Total input rating of all

connected appliances

kW " kBtu/h

21 70

27 91

31 105

36 119

41 140

51 175

USGPH

0.50

0.65

0.75

0.85

1.00

1.25

Flue inside diameter(in) Minimum base temperature (°F)

for chimney height(if)of:

Min. " Max. " 11 ' 20 " 28 " 36

3 5 300 400 535 725

3 5 275 340 430 535

4 5 260 320 380 475

4 5 250 300 355 430

4 6 225 300 365 430

4 6 240 275 320 365

4.3) Side-wall venting, DV-2000 TM Direct Vent

System:

The furnace can be side-wall vented without the use of a side-wall

power ventor using the new DV -2000 TM venting system with the high

static pressure Beckett AFII and Riello 40-BF oil burners. Outdoor

combustion air must be directly connected to the burner of the

DV-2000 TM venting system w ill not function.

TM

The notable characteristics of the DV-2000 system are as follows:

2,

3,

4,

Certified to use the following materials for ducting the intake air

from the terminal to the burner; Schedule 40 PVC DWV,

Schedule 40 ABS DWV, And ASTM 2729 Sewer Pipe.

One hole of minimal size (6") is required to be cut in the side-

wall, and the terminal is designed to fit through a minimum 2 X 8

joist space.

Incorporates a vent blockage safety shutdown system. If the vent

or intake opening ever becomes partially or fully blocked, the

burner will shut down before a #1 smoke occurs.

The intake and vent circuits within the terminal can be accessed

for cleaning.

TM

There are 3 main components to the DV-2000 system; the VTK vent

terminal kit, the IFV insulated flexible venting material and the field-

supplied 3" PVC or ABS intake piping.

Poison carbon monoxide gas hazard

Even though the flexible venting is insulated, it

cannot be run through an unheated space,

To do so could cause residual condensation inside

the stainless steel liner, which may eventually

perforate the liner and allow vent gasses to enter

the dwelling.

Vent terminal kits - DV-2000TM:

The certified standard vent terminal kit is Model No. VTK-1 or VTK-2,

and is suitable for installation in walls up to 14" thick. An altemate kit,

Model VTK-1-DW or VTK-2-DW is available to accommodate walls up

to 25" thick. Both kits contain the following items to complete the hook-

up to the venting and furnace:

1 Terminal

2 Sealing Clamps

1 Side-wall Venting Breech Plate

2 Sealing Strips

1 Inner Wall Plate

1 Pressure Control with Tubing

Loading...

Loading...