2 InsulatedQuick-connectTerminals

3 StainlessSteelScrews

6 Selftappingstainlesssteelscrews

Insulatedflexible venting - DV-2000TM:

steel corrugated flexible liner surrounded by a thick insulation blanket

and covered with an outer layer of flexible corrugated aluminium

sleeve to protect the insulation. Splicing vent lengths together is

prohibited. The maximum and minimum continuous vent lengths

permitted for installation are:

The certified venting materials come in 3 lengths, Model No. IFV3-15,

IFV3-23 and IFV3-30 (or IFV4-15, IFV4-23 and IFV4-30 for 160

models) are corresponding to 15', 23' and 30' continuous lengths of

vent. The vent construction is coaxial and incorporates a stainless

5 feet minimum 30 feet maximum

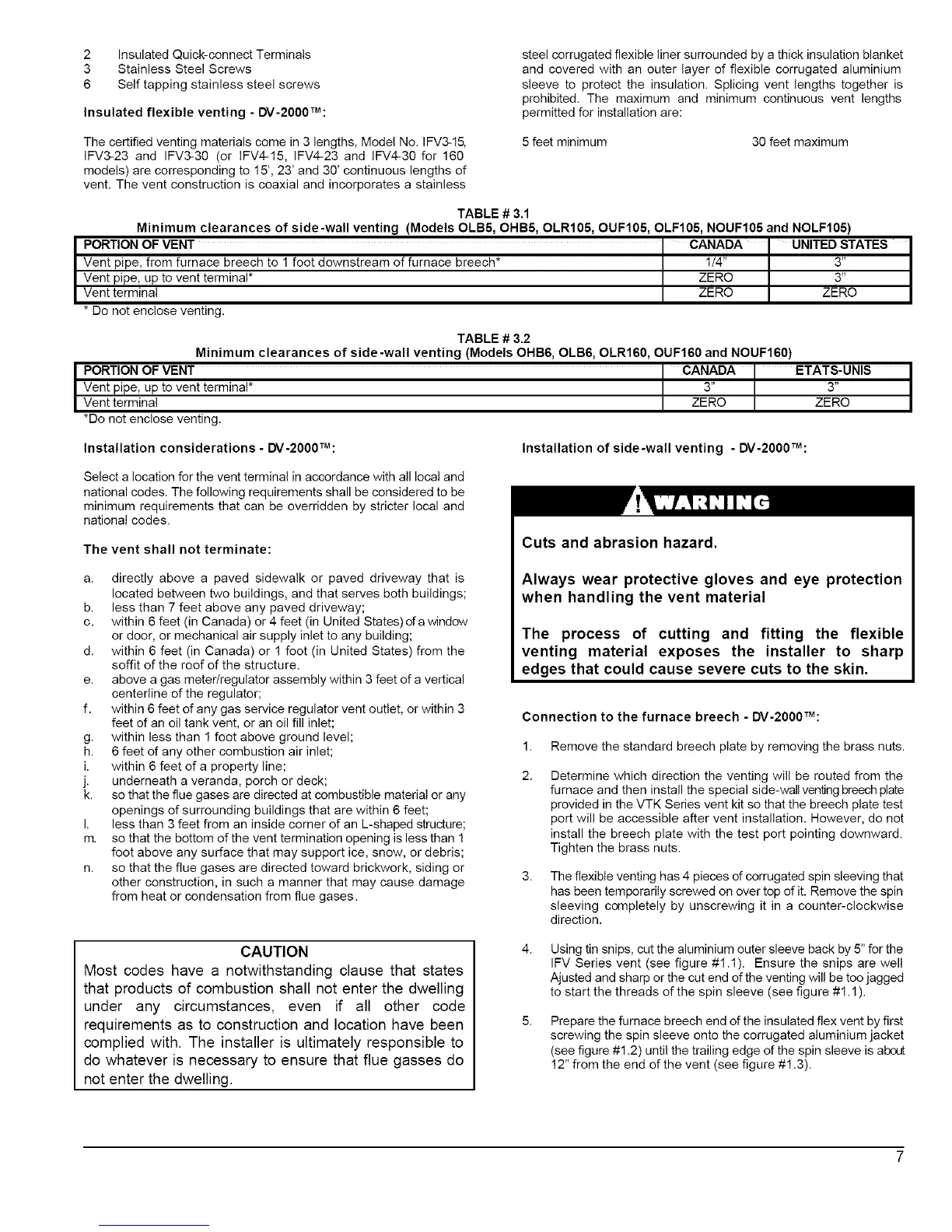

TABLE # 3.1

Minimum clearances of side-wall venting (Models OLB5, OHB5, OLR105, OUF105, OLF105, NOUF105 and NOLF105)

PORTION OF VENT CANADA UNITED STATES

Vent pipe, from furnace breech to 1 foot downstream of furnace breech* 1/4" 3"

Vent pipe, up to vent terminal* ZERO 3"

Vent terminal ZERO ZERO

* Do not enclose venting.

TABLE # 3.2

Minimum clearances of side-wall venting (Models OHB6, OLB6, OLR160, OUF160 and NOUF160)

I PORTION OF VENT CANADA ETATS-UNIS I

Vent pipe, up to vent terminal* 3" 3"

Vent terminal ZERO ZERO

*Do not enclose venting.

Installation considerations - DV'2000TM:

Installation of side-wall venting - DV-2OOOTM:

Select a location for the vent terminal in accordance with all local and

national codes. The following requirements shall be considered to be

minimum requirements that can be overridden by stricter local and

national codes.

The vent shall not terminate:

a. directly above a paved sidewalk or paved driveway that is

located between two buildings, and that serves both buildings;

b. less than 7 feet above any paved driveway;

c. within 6 feet (in Canada) or 4 feet (in United States) of a window

or door, or mechanical air supply inlet to any building;

d. within 6 feet (in Canada) or 1 foot (in United States) from the

soffit of the roof of the structure.

e. above a gas meter/regulator assembly within 3 feet of a vertical

centerline of the regulator;

f. within 6 feet of any gas service regulator vent outlet, or within 3

feet of an oil tank vent, or an oil fill inlet;

g. within less than 1 foot above ground level;

h. 6 feet of any other combustion air inlet;

i. within 6 feet of a property line;

j. underneath a veranda, porch or deck;

k. so that the flue gases are directed at combustible material or any

openings of surrounding buildings that are within 6 feet;

I. less than 3 feet from an inside corner of an L-shaped structure;

m. so that the bottom of the vent termination opening is less than 1

foot above any surface that may support ice, snow, or debris;

n. so that the flue gases are directed toward brickwork, siding or

other construction, in such a manner that may cause damage

from heat or condensation from flue gases.

Cuts and abrasion hazard.

Always wear protective gloves and eye protection

when handling the vent material

The process of cutting and fitting the flexible

venting material exposes the installer to sharp

edges that could cause severe cuts to the skin.

Connection to the furnace breech - DV'2000TM:

1. Remove the standard breech plate by removing the brass nuts.

2,

Determine which direction the venting will be routed from the

furnace and then install the special side-wall venting breech plate

provided in the VTK Series vent kit so that the breech plate test

port will be accessible after vent installation. However, do not

install the breech plate with the test port pointing downward.

Tighten the brass nuts.

3,

The flexible venting has 4 pieces of corrugated spin sleeving that

has been temporarily screwed on over top of it. Remove the spin

sleeving completely by unscrewing it in a counter-clockwise

direction.

CAUTION

Most codes have a notwithstanding clause that states

that products of combustion shall not enter the dwelling

under any circumstances, even if all other code

requirements as to construction and location have been

complied with. The installer is ultimately responsible to

do whatever is necessary to ensure that flue gasses do

not enter the dwelling.

4,

5,

Using tin snips, cut the aluminium outer sleeve back by 5" for the

IFV Series vent (see figure #1.1). Ensure the snips are well

Ajusted and sharp or the cut end of the venting will be too jagged

to start the threads of the spin sleeve (see figure #1.1).

Prepare the furnace breech end of the insulated flex vent by first

screwing the spin sleeve onto the corrugated aluminium jacket

(see figure #1.2) until the trailing edge of the spin sleeve is about

12" from the end of the vent (see figure #1.3).

Loading...

Loading...