reversingvalveandauxiliaryheatoutputsand"hold"

thedefrosttimeruntilthenextcallforheat,atwhichtime

thedefrostcyclewillbecompleted.

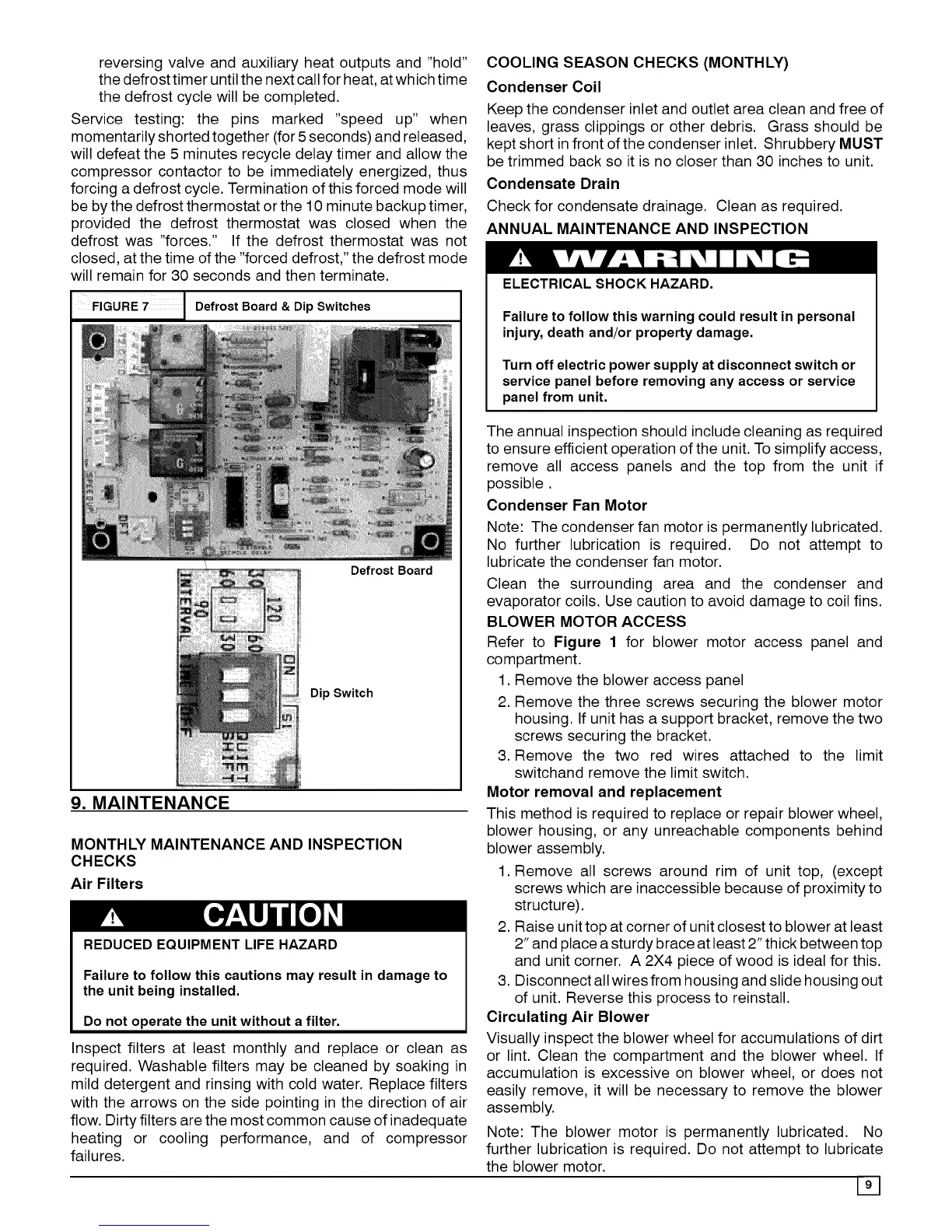

Servicetesting:the pins marked"speedup" when

momentarilyshortedtogether(for5seconds)andreleased,

willdefeatthe5 minutesrecycledelaytimerandallowthe

compressorcontactorto beimmediatelyenergized,thus

forcingadefrostcycle.Terminationofthisforcedmodewill

bebythedefrostthermostatorthe10minutebackuptimer,

providedthe defrostthermostatwas closedwhenthe

defrostwas"forces."If the defrostthermostatwasnot

closed,atthetimeofthe"forceddefrost,"thedefrostmode

willremainfor30secondsandthenterminate.

Defrost Board & Dip Switches

Defrost Board

Dip Switch

9. MAINTENANCE

MONTHLY MAINTENANCE AND INSPECTION

CHECKS

Air Filters

REDUCED EQUIPMENT LIFE HAZARD

Failure to follow this cautions may result in damage to

the unit being installed.

Do not operate the unit without a filter.

Inspect filters at least monthly and replace or clean as

required. Washable filters may be cleaned by soaking in

mild detergent and rinsing with cold water. Replace filters

with the arrows on the side pointing in the direction of air

flow. Dirty filters are the most common cause of inadequate

heating or cooling performance, and of compressor

failures.

COOLING SEASON CHECKS (MONTHLY)

Condenser Coil

Keep the condenser inlet and outlet area clean and free of

leaves, grass clippings or other debris. Grass should be

kept short in front of the condenser inlet. Shrubbery MUST

be trimmed back so it is no closer than 30 inches to unit.

Condensate Drain

Check for condensate drainage. Clean as required.

ANNUAL MAINTENANCE AND INSPECTION

ELECTRICALSHOCKHAZARD.

Failure to follow this warning could result in personal

injury, death and/or property damage.

Turn off electric power supply at disconnect switch or

service panel before removing any access or service

panel from unit.

The annual inspection should include cleaning as required

to ensure efficient operation of the unit. To simplify access,

remove all access panels and the top from the unit if

possible.

Condenser Fan Motor

Note: The condenser fan motor is permanently lubricated.

No further lubrication is required. Do not attempt to

lubricate the condenser fan motor.

Clean the surrounding area and the condenser and

evaporator coils. Use caution to avoid damage to coil fins.

BLOWER MOTOR ACCESS

Refer to Figure 1 for blower motor access panel and

compartment.

1. Remove the blower access panel

2. Remove the three screws securing the blower motor

housing. If unit has a support bracket, remove the two

screws securing the bracket.

3. Remove the two red wires attached to the limit

switchand remove the limit switch.

Motor removal and replacement

This method is required to replace or repair blower wheel,

blower housing, or any unreachable components behind

blower assembly.

1. Remove all screws around rim of unit top, (except

screws which are inaccessible because of proximity to

structure).

2. Raise unit top at corner of unit closest to blower at least

2" and place a sturdy brace at least 2" thick between top

and unit corner. A 2X4 piece of wood is ideal for this.

3. Disconnect all wires from housing and slide housing out

of unit. Reverse this process to reinstall.

Circulating Air Blower

Visually inspect the blower wheel for accumulations of dirt

or lint. Clean the compartment and the blower wheel. If

accumulation is excessive on blower wheel, or does not

easily remove, it will be necessary to remove the blower

assembly.

Note: The blower motor is permanently lubricated. No

further lubrication is required. Do not attempt to lubricate

the blower motor.

[2J

Loading...

Loading...