UK

CompactModul Metall CR2033

5

● The COB IDs of the PDOs as well as the transmission type of the individual

PDOs can be configured�

● The module expects a synch object�

The CAN identifier of the synch object can be configured�

● The module supports "node guarding" and "heartbeat"�

The "guard time",the "life time factor" and the "heartbeat time"can be config-

ured� When there are no heartbeat or node guarding signals, the outputs are

automatically switched off by the operating system�

● The module generates an emergency object� The COB ID of the EMCY object

can be configured�

● The module stores the last error�

The error code of the corresponding emergency object is stored�

● The module supports a reset function, i�e� assignment of the parameters to the

factory default values* upon request�

The CR2033 I/O module ist not approved for safety-relevant tasks in the field of

safety of persons�

*) factory default values (→ 8.1 Parameter list)

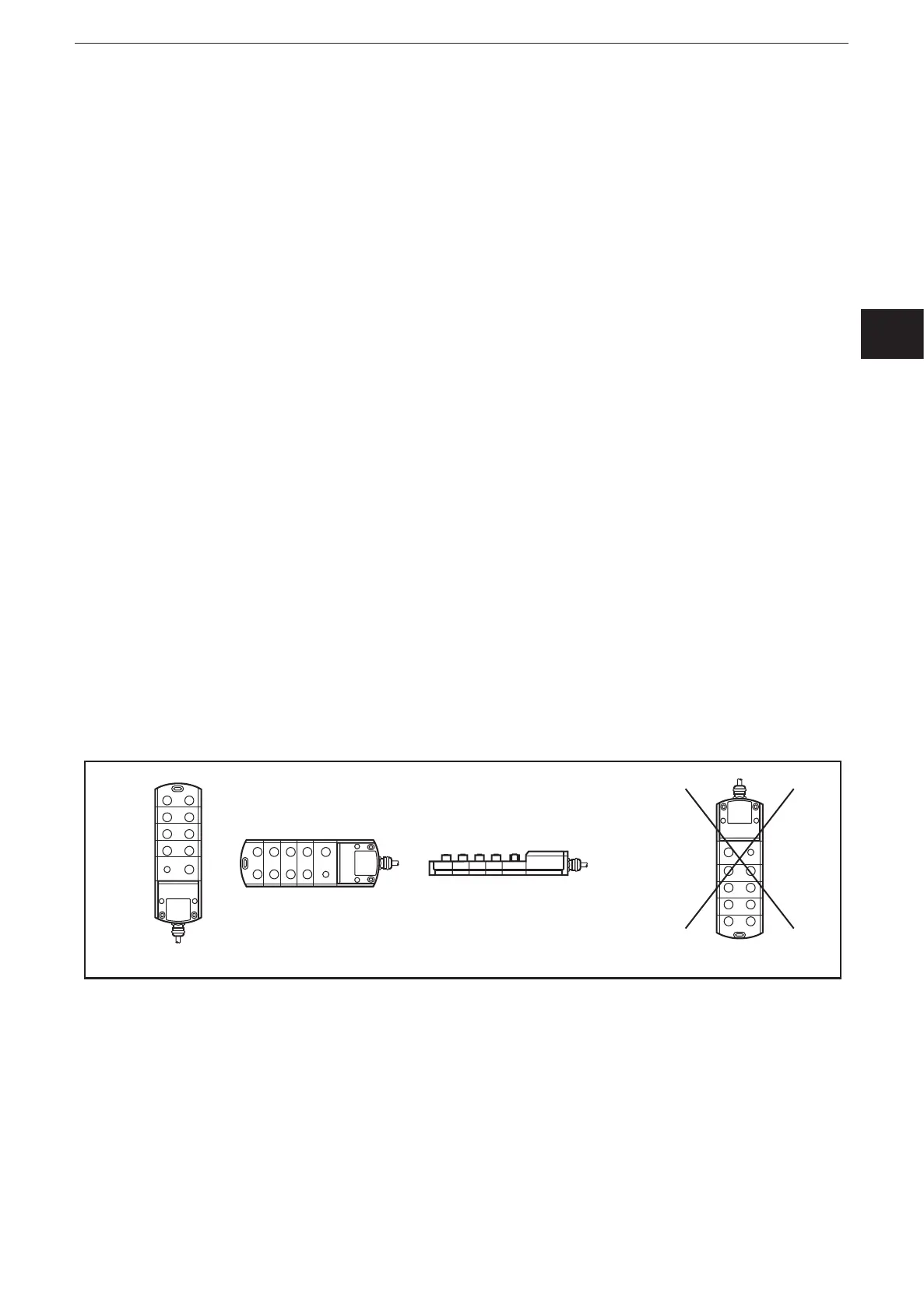

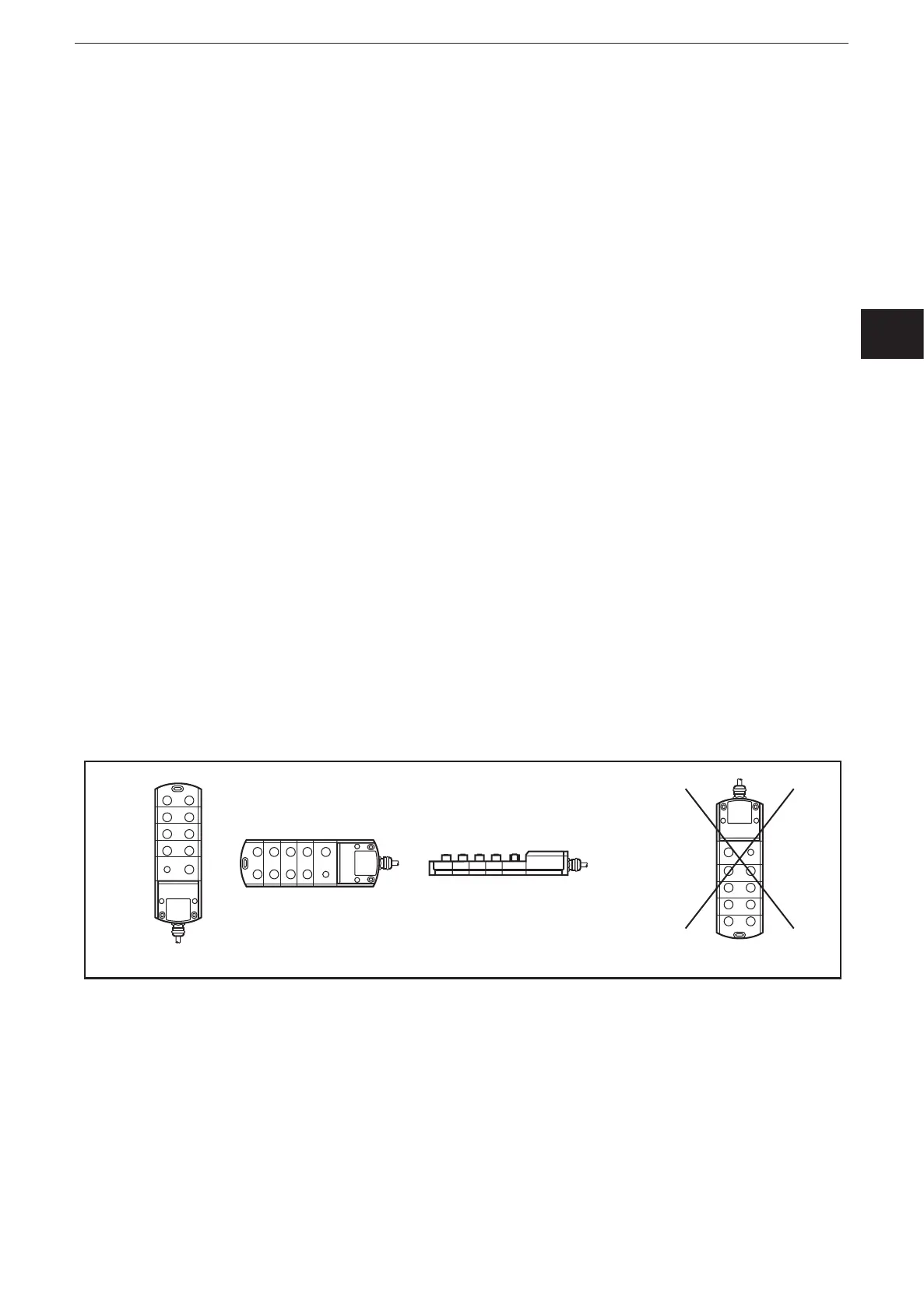

4 Mounting

To protect the module against mechanical stress it must be mounted so that it lies

completely flat on an even mounting surface� To do so, three cylinder screws with

hexagon socket (M5 x L) to DIN 912 or DIN 7984 must be used�

preferred Mounting variants

wrong

To avoid contact corrosion between the mounting screws and the module housing,

do not use any stainless steel screws or nickel-plated screws!

In very corrosive environments such as extremely salty air, we recommend to use

screws with surface finishing on a zinc/nickel basis with thick-film passivation and

sealing� For normal corrosive requirements zinc-plated screws are sufficient�

Loading...

Loading...