12 13

Pressing the +/- buttons (H or I) increases or reduces the

temperature.

RT

The heating function is started and stopped by pressing the

„Temp“ button (J).

Function Heating

ECO mode

RO/RT

The heat generated in the device can be reduced by lowering the

power of the input coils.

Pressing the “ECO Mode“ (F) key to reduce the current power

setting. ECO mode is indicated by an “E” preceding the speed.

When the power is set to ECO mode, the speed is limited to 600

rpm.

To make the stirring power more independent from the speed

range, press the “ECO Mode“ membrane key (F) and then select

one of the following setting options.

P50 (Stirring power 50% independent of the speed range)

P75 (Stirring power 75% independent of the speed range)

P100 (Stirring power 100% independent of the speed range)

---- (Standard stirring performance with the stirring power

regulated by the speed)

RO/RT

The (G) key activates the “Reverse Rotation” function.

When the „Reverse Rotation“ function is switched on, a decimal

point (K) appears in the LCD display.

The running time (30, 60, 90 or 120sec) is set by pressing the (G)

key followed by the +/- keys.

After the preset running time, the drive is switched off and

restarted at minimum speed in the opposite direction after a

pause specific to the speed.

In this way the magnetic rod is captured and any liquid still

rotating is gradually slowed down. Then the drive accelerates to

the target speed.

Note: If the “Reverse Rotation” key (G) is pressed again, the drive

will keep rotating in the same direction.

When the device is started up again, the drive will rotate in the

direction last set.

Direction of rotation reversal

RO/RT

To toggle between modes, press the Start/Stop key (C) when

switching on.

Operating Mode “A”

All the parameter settings are retained when the device is

switched off or disconnected from the mains.

The “Start/Stop” (C) key starts the device with the set parameters.

Operating Mode “B“

All parameter settings, including “Start/Stop”, are saved when the

device is switched off.

Operating Mode “D“

In the D mode the device operates as per the A mode but with the

following exception:

- Switch on and then press the “Temp” membrane key to confirm

the safety temperature.

- The value flashes until it is confirmed.

Factory setting: mode A

Operating modes

The equipment is maintenance-free. It is only subject to the natu-

ral wear and tear of components and their statistical failure rate.

Cleaning

- For cleaning disconnect the mains plug!

- Use only cleaning agents which have been approved by IKA to

clean the devices:

These are: water (containing surfactant) and isopropyl alcohol.

Maintenance and cleaning

- Wear protective gloves during cleaning the devices.

- Electrical devices may not be placed in the cleansing agent for

the purpose of cleaning.

- Do not allow moisture to get into the device when cleaning.

- Before using another than the recommended method for

cleaning or decontamination, the user must ascertain with IKA

that this method does not destroy the device.

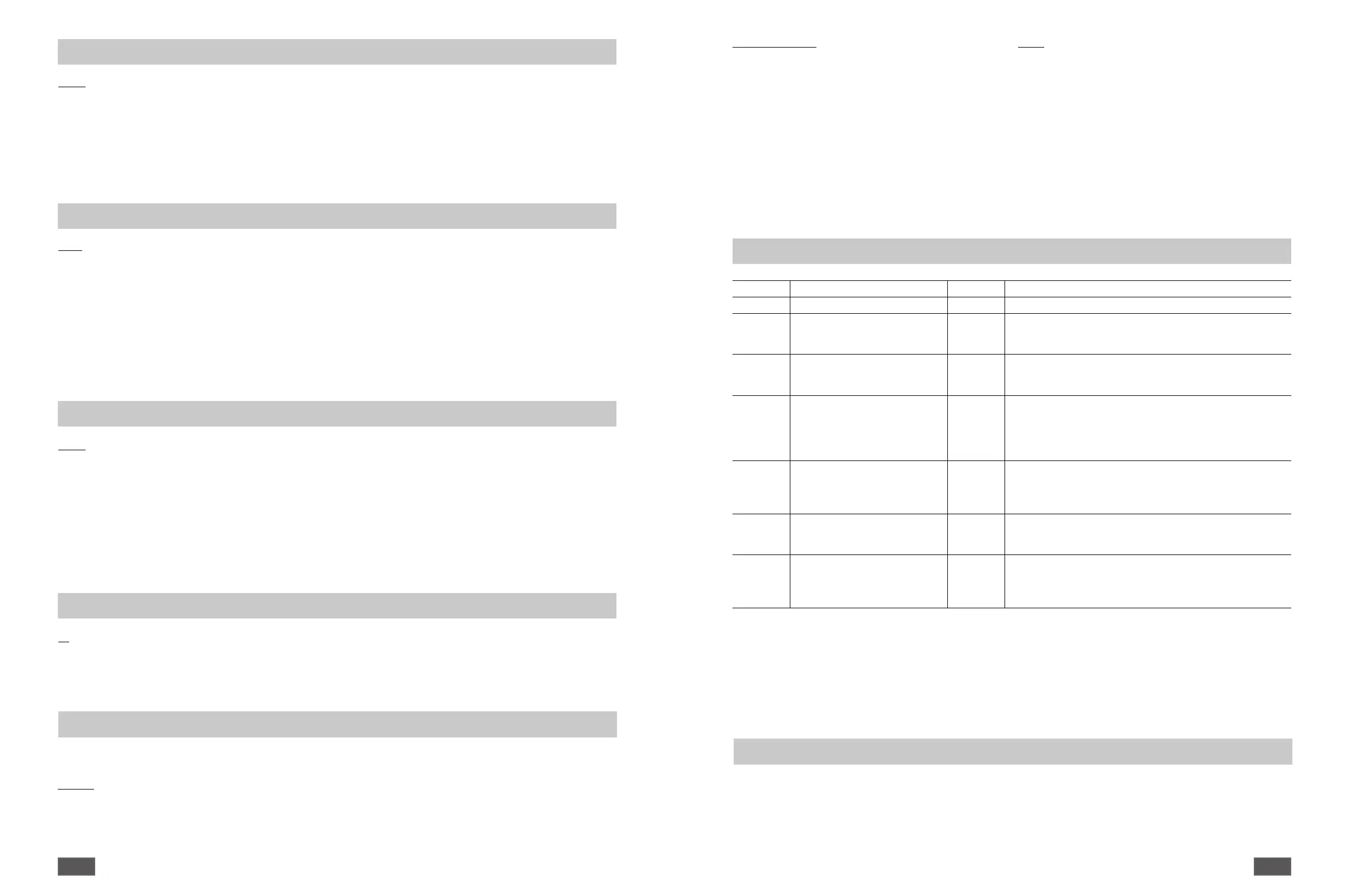

Error Codes (RT 5/10/15)

Accessories

• Stirring bar: ø 8 mm; length 30 mm

• RSE Stirring bar remover

Ordering spare parts

When ordering spare parts, please give:

- Device type

- Manufacturing number, see type plate

- Software version

- Item number and designation of the spare part,

see www.ika.com.

Repair

Please send instrument in for repair only after it has been

cleaned and is free from any materials which may consti-

tute a health hazard.

For this you should request the “Safety Declaration (Deconta-

mination Certificate)” from IKA, or use the download printout

of it from the IKA website www.ika.com.

Return the instrument in its original packaging. Storage packaging

is not sucient. Also, please use suitable shipping package mate-

rials.

Error code Cause Effect Solution

Er03 Temperature inside device is too high Heating off - Switch off device and allow to cool down

Er21 Safety relay doesn‘t open during test Heating off - Switch off device

- Warning! Only to be carried out by authorised service personnel:

Check PCB

Er22 Safety temperature is too low during

test

Heating off - Switch off device

- Warning! Only to be carried out by authorised service personnel:

Check PCB and safety temperature sensor

Er25 Heating and switching element

monitoring

Heating off - Check the external temperature controller

- Switch off device

- Warning! Only to be carried out by authorised service personnel: Carry

out an internal test on the device to check the plug-in connector for

the heating element, the safety temperature sensor or the PCB

Er26 Difference between temperature of

safety sensor and temperature of

control sensor: control temperature

> (safety temperature + 40 K)

Heating off - Switch off device

- Warning! Only to be carried out by authorised service personnel: Carry

out an internal test on the device to check the plug-in connector for

the temperature sensor

Er31 Triac error detection doesn‘t work Heating off - Switch off device

- Warning! Only to be carried out by authorised service personnel:

Check PCB

Er46 Difference between temperature of

safety sensor and temperature of

control sensor: safety temperature

> (control temperature + 40 K)

Heating off - Switch off device

- Warning! Only to be carried out by authorised service personnel:

Carry out an internal test on the device to check the plug-in connec-

tor for the temperature sensor

If the actions described fail to resolve the fault or another error code is displayed then take one of the following steps:

- Please contact the service department;

-

Send the device for repair, including a short description of the fault.

Loading...

Loading...