The open up a wide range of possibilities for dispersion techno-

logy in the conventional laboratory with a respective performan-

ce output of approximately 350 watts at 24,000 1/min in the

case of the T25 basic.

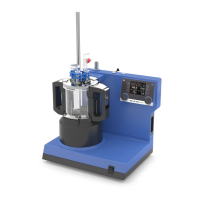

The ULTRA-TURRAX

®

T 25 basic are dispersion units which, in

connection with a dispersion tool, manufacture emulsions and

dispersions. The dispersion devices should be operated on a

laboratory stand.

The

ULTRA-TURRAX

®

T 25 basic are entirely pre-assembled.

Please unpack the device and/or dispersion tools carefully and

inspect them for any damage. It is important that any damage is

detected as soon as the items are unpacked. A record of the

relevant facts may be required (railway, mail or carrier). The devi-

ce delivery quantity includes: a driving unit, an extension arm, a

hexagon socket screw, a tool set and an operating manual.

You have acquired a high-quality product. Used in combination

with an

S 25 series dispersion tool, the drive unit is a high-speed

dispersing and emulsifying unit capable of handling free-flowing

and liquid media in batches.

Dispersion is the dissolution and diffusion of a solid, liquid or

gaseous phase in a continuum that is not consolute with that

phase.

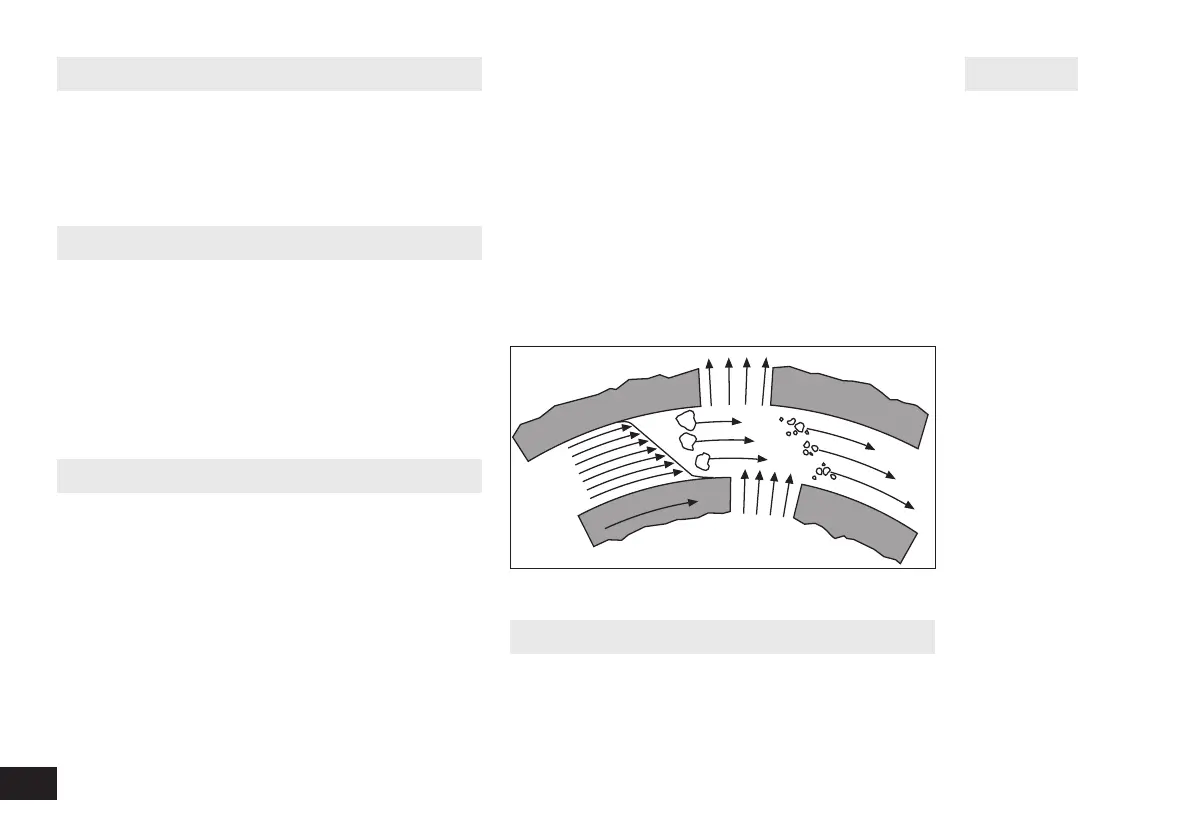

The rotor/stator principle:

Due to the high rotation speed of the rotor, the medium to be

processed is automatically drawn axially into the dispersion

head and then forced radially through the slots in the rotor/stator

arrangement. The high accelerations acting on the material

produce extremely strong shear and thrust forces. In addition,

high turbulence occurs in the shear gap between rotor and

stator, which provides optimum mixing of the suspension.

The dispersion effectiveness is heavily dependent on the

product of the shear gradient and the time the particles spend in

the shear zone. The optimum range for the circumferential

velocity of the rotor/stator arrangement is 10-24 m/s.

A processing time of a few minutes is usually sufficient to

produce the desired fineness. Long processing times bring only

insignificant improvements in the obtainable fineness; the

energy expended serves merely to increase the temperature of

the medium.

18

T25 1096EU

Unpacking

Useful information

Proper use

Drive unit

Loading...

Loading...