6

STCS ed 07/02 CAESAR Star

Technical Documentation

Technical Documentation

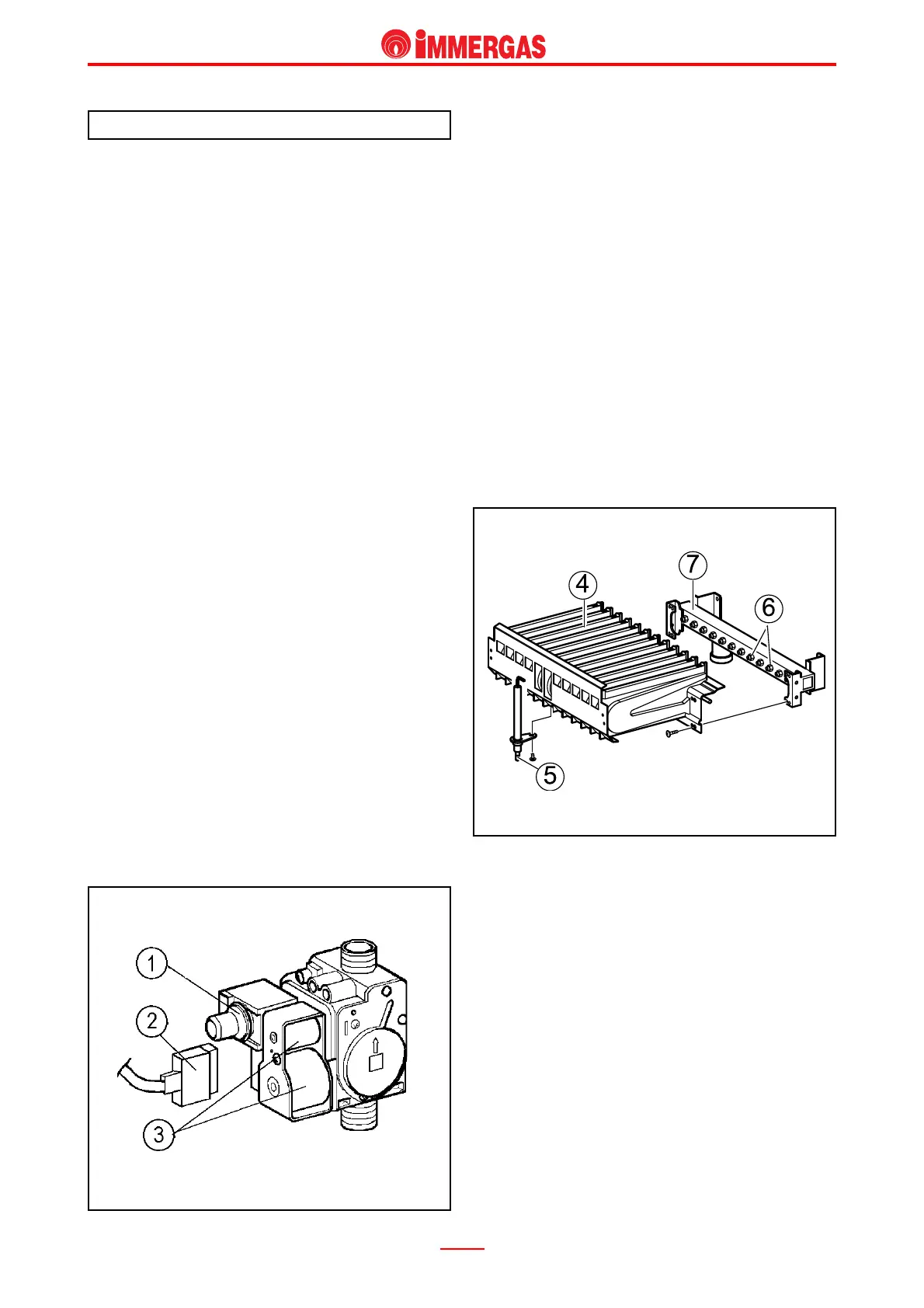

The circuit consists of an atmospheric burner and a

modulating type valve for gas combustion and gas flow

adjustment respectively.

Operation.

When the main coils (3) are energised, both inner val-

ve shutters open, allowing the gas to flow towards the

burner.

The flow rate/outlet pressure is regulated by means of

the gas valve stabiliser and the modulation coil (1).

By means of the burner nozzles (6), the fuel is injected

into the venturi pipes (ramps) inside which the air-gas

mix is obtained that is ignited by the spark from the

ignition electrode (5).

Modulating gas valve.

The gas valve (SIT 845) features two main coils (3)

and a modulation coil (1) controlled by the modulation

board.

The maximum and minimum outlet pressure settings

can be made on this valve (see gas adjustments).

Main electrical coils (3).

Two coils of the ON-OFF type energised (230V AC)

by the adjustment board when the burner has to be

ignited.

These are electrically connected in parallel and

energised by mains power through a special connec-

tor (2).

Modulation coil (1).

This is a low-voltage coil controlled by the modulation

board.

This controls the gas valve stabiliser and permits

changing the outlet pressure in a way proportionate to

the DC signal that runs through it.

Gas circuit.

Burner.

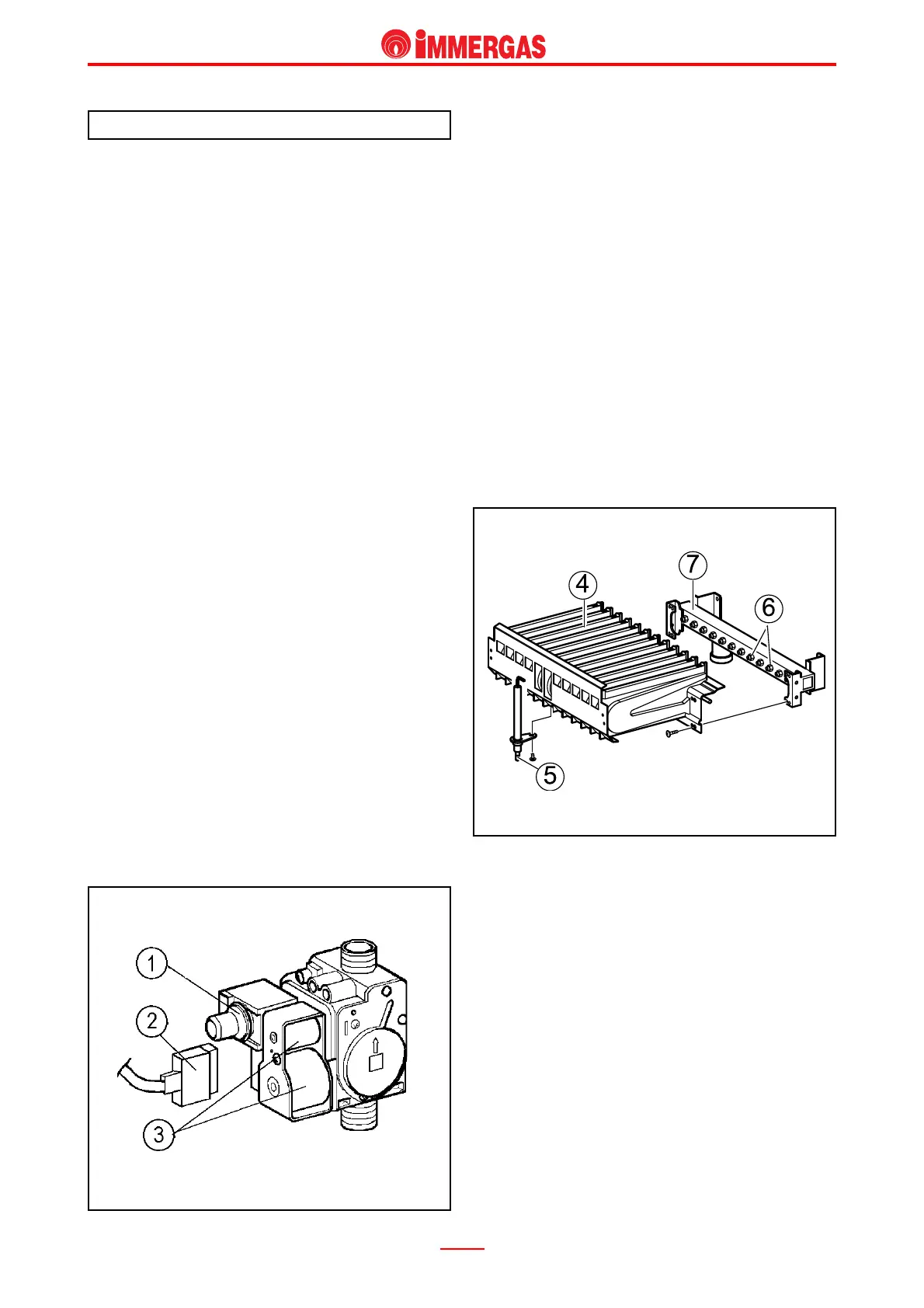

The burner consists of 12 horizontal venturi pipes (4)

in which the gas is injected by an equal number of

nozzles (6) mounted on the special header (7).

Ignition occurs by means of the adjustment board which

controls the ignition/detection electrode (5).

Ignition and detection electrode (5).

During ignition, this is controlled by the adjustment

board which produces an electrical charge between

its end and the burner surface that ignites the air-gas

mix.

When the burner is on, it also detects the flame on the

burner enabling the adjustment board to conclude the

ignition cycle and change the gas pressure according

to need.

This is positioned on the front of the burner in line with

the centre ramp.

Loading...

Loading...