7

STCS ed 07/02 CAESAR Star

Technical Documentation Technical Documentation

Gas adjustments.

Max and minimum gas pressure adjustments can be

made by means of the gas valve respecting the values

shown on the tables relating to the type of

corresponding gas.

Measurements are made using a U-shaped differen-

tial pressure gauge connected to a “Y” to be placed in

between in the small silicone tube connecting the gas

valve to the sealed chamber and to the gas valve outlet

pressure point.

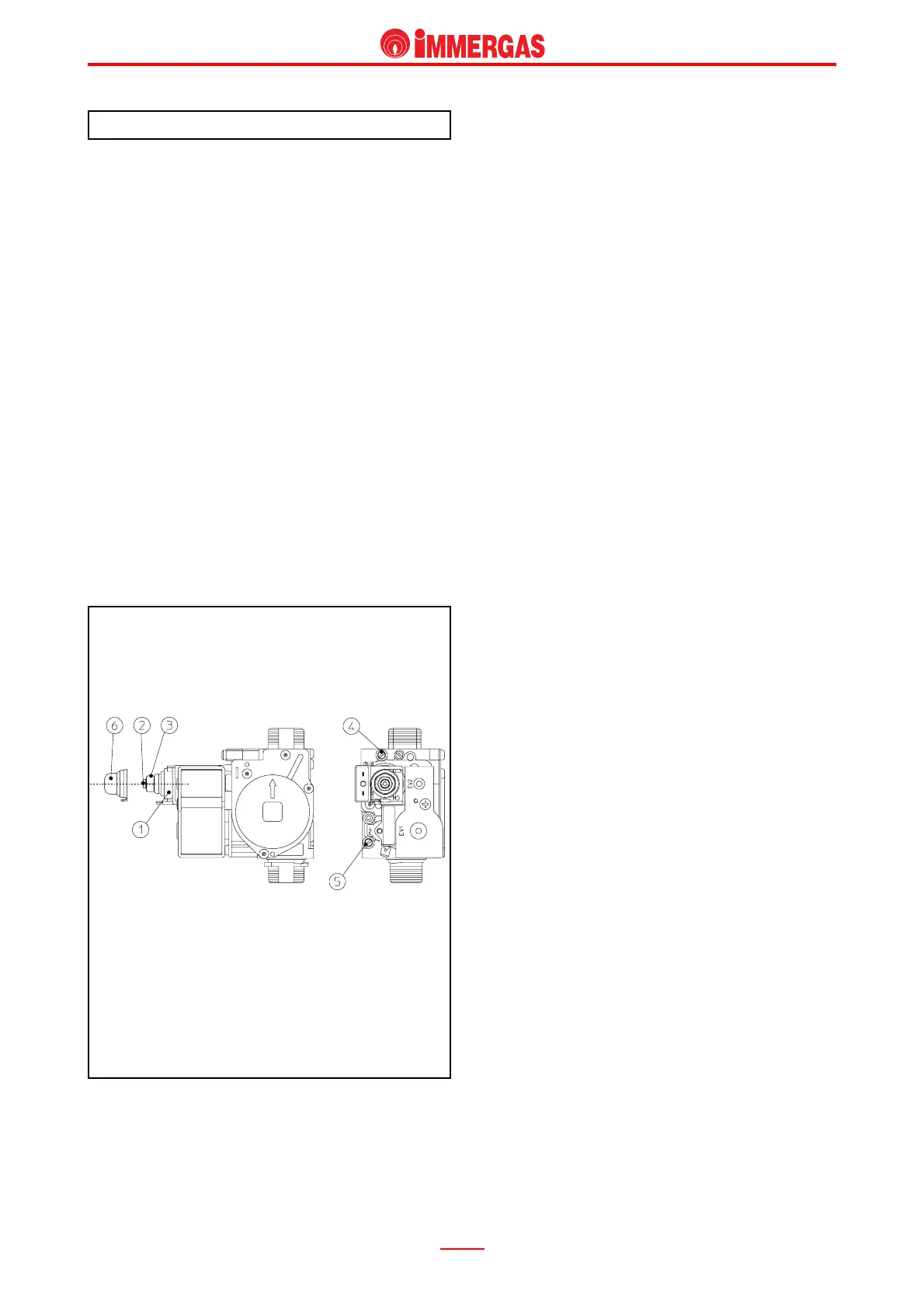

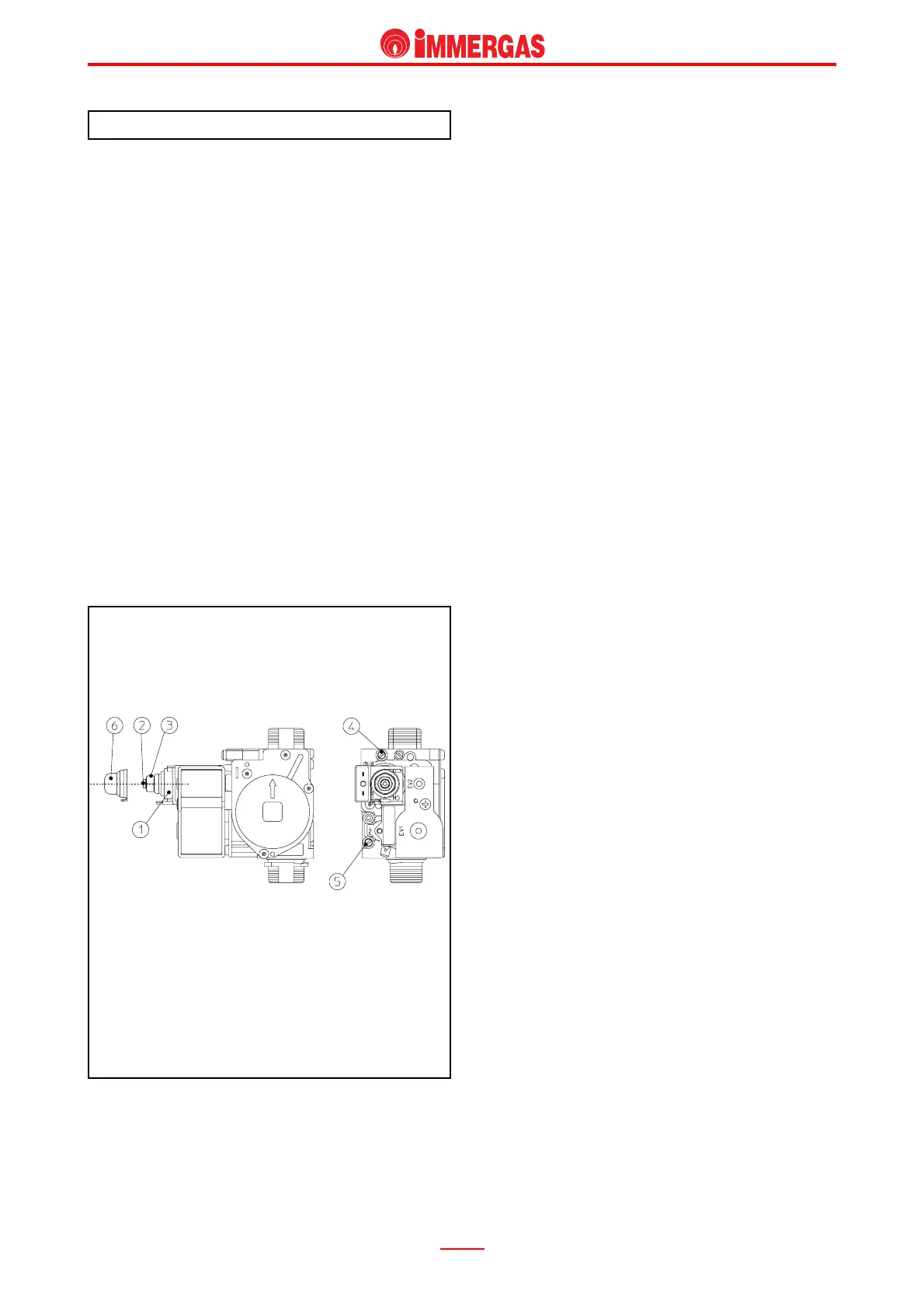

Valve Sit 845.

Maximum pressure setting.

Draw d.h.w. after setting the temperature switch at

maximum.

Turn the brass nut (3) clockwise to increase the

pressure to the burner and anticlockwise to decrease

it.

Adjusting minimum pressure

(to be done after adjusting max pressure).

After interrupting power to the modulation coil, turn the

crosshead screw (2) clockwise to increase pressure

to the burner and anticlockwise to decrease pressure.

Key:

1 - Coil

2 - Minimum output setscrew

3 - Maximum output setscrew

4 - Gas valve outlet pressure point

5 - Gas valve inlet pressure point

6 - Protection cap

Valvola Sit 845

Changing type of gas.

Adaptation to a type of gas different to that for which

the boiler is intended, can be done by using the special

kits (natural gas or LPG).

The changeover consists in replacing the burner

nozzles and in moving to the modulation board of the

“NATURAL GAS- LPG” (S1) bridge.

The minimum and maximum pressures are then set

on the gas valve in the way described above.

The burner ignition pressure is not adjusted

because the type of board operation does not require

such setting (see modulation board operation).

NOTE: any changes made to enable the unit to use

G110 gas (town gas), besides the use of a special

nozzle kit and performance of the same operations

indicated above, also requires shifting jumper switch

“S1” onto switch “S2” on the electronic board (see

modulation board adjustments).

Loading...

Loading...