6

5

1

3

2

7

8

5

9

7

4

S

A

C82

1-22

C42

C52

1-23

1-25

C82

1-24

11 - IE

INSTALLATORUSERMAINTENANCE

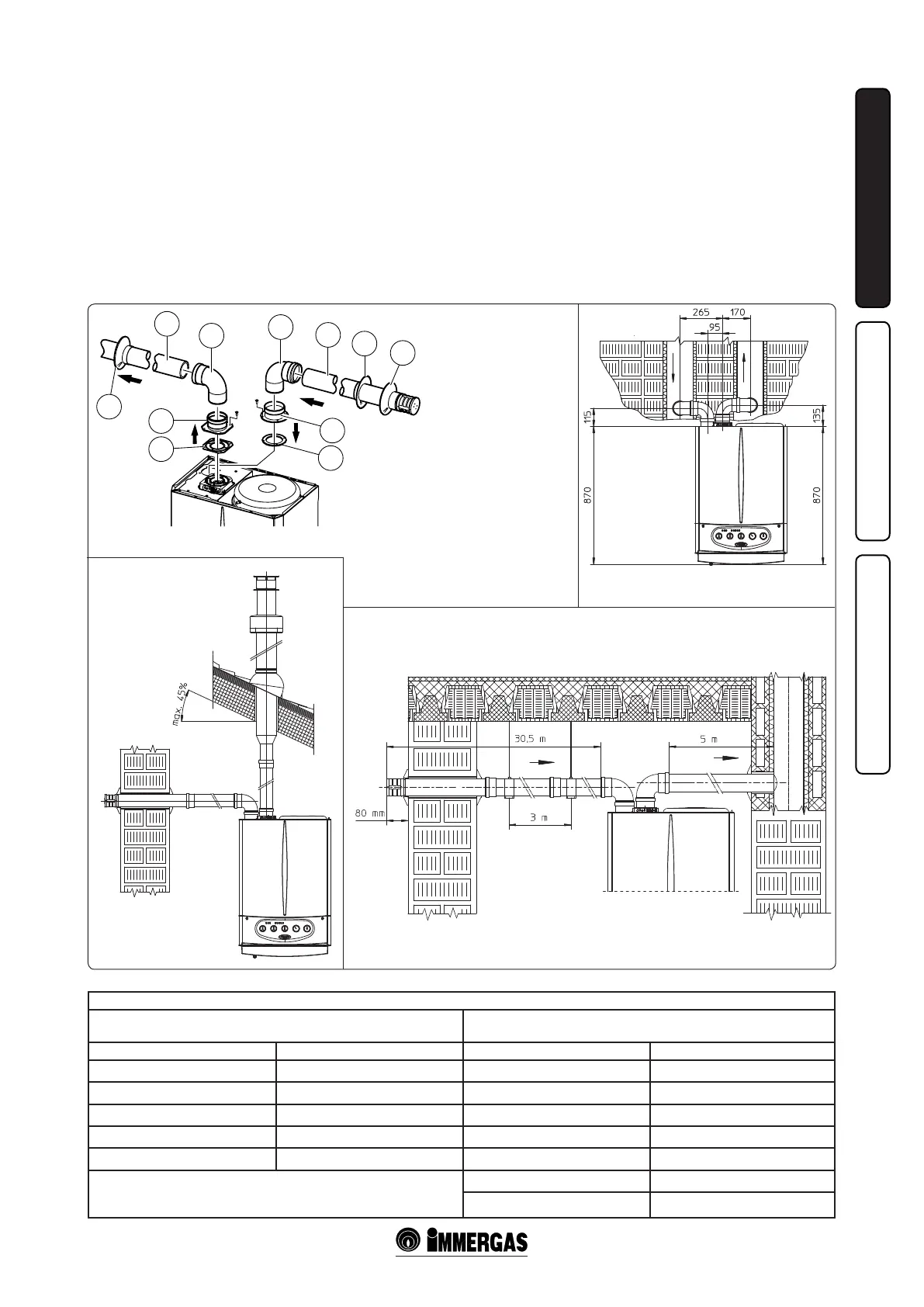

Max. usable lengths (including intake terminal with grill and two 90° bends)

NON-INSULATED

PIPE

INSULATED

PIPE

Exhaust (m) Intake (m) Exhaust (m) Intake (m)

1 36,0* 6 29,5*

2 34,5* 7 28,0*

3 33,0* 8 26,5*

4 32,0* 9 25,5*

5 30,5* 10 24,0*

* e air intake pipe can be increased to 2.5 metres if the exhaust bend is

eliminated, 2 metres if the air intake bend is eliminated, and 4.5 metres

eliminating both bends.

11 22,5*

12 21,5*

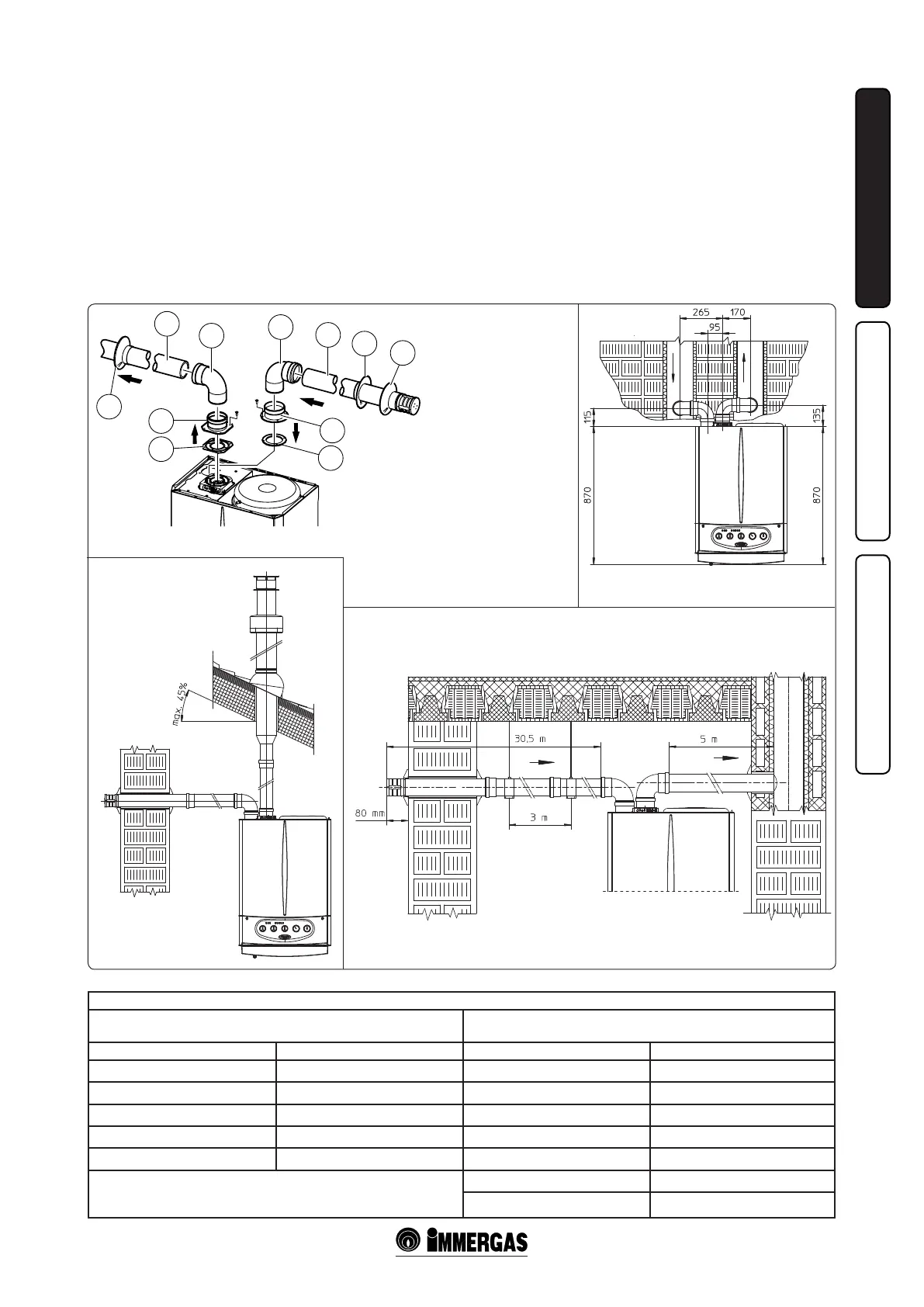

e kit includes:

N°1 - Exhaust seal (1)

N°1 - Female intake ange (3)

N°1 - Flange seal (2)

N°1 - Female exhaust ange (4)

N°1 - 90° bend Ø 80 (5)

N°1 - Intake terminal Ø 80 (6)

N°1 - Internal rings (7)

N°1 - External ring (8)

N°1 - Exhaust pipe Ø 80 (9)

separator Ø 80/80 to a concentric pipe), the

maximum extension can be calculated by

using a resistance factor for each component

or the the equivalent length. e sumof these

resistance factors must not exceed 100.

• Temperature loss in fume ducts (Fig. 1-25). To

prevent problems of fume condensate in the

exhaust pipe Ø 80, due to fume cooling through

the wall, the length of the pipe must be limited to

just 5 m. If longer distances must be covered,

use Ø 80 pipes with insulation (see insulated

separator kit Ø 80/80 chapter).

Insulated separator kit Ø 80/80. Kit assembly

(Fig. 1-26): install flange (4) on the central

hole of the boiler, tting seal (1), and tighten

with the at-tipped hex screws included in the

kit. Remove the at ange on the lateral hole

(depending on installation requirements) and

replace with ange (3) inserting seal (2) already

tted on the boiler and tighten using the self-

tapping screws supplied. Insert and slide cap

(6) onto bend (5) from the male side (smooth),

and join bends (5) with the male side (smooth)

in the female side of ange (3). Fit bend (11)

with the male side (smooth) in the female side

of ange (4). Fit the male end (smooth) of the

intake terminal (7) up to the stop on the female

end of the bend (5), making sure you have already

inserted the rings (8 and 9) that ensure correct

installation between pipe and wall, then x the

closing cap (6) on the terminal (7). Join the

exhaust pipe (10) with the male side (smooth) in

the female side of the bend (11) to the end stop,

ensuring that the washer (8) is already inserted

for correct installation between the pipe and ue.

• Coupling of extension pipes and elbows. To

install snap-t extensions with other elements

of the fume exhaust system, proceed as follows:

t the male end (smooth) of the concentric

pipe or concentric elbow up to the stop on the

Loading...

Loading...