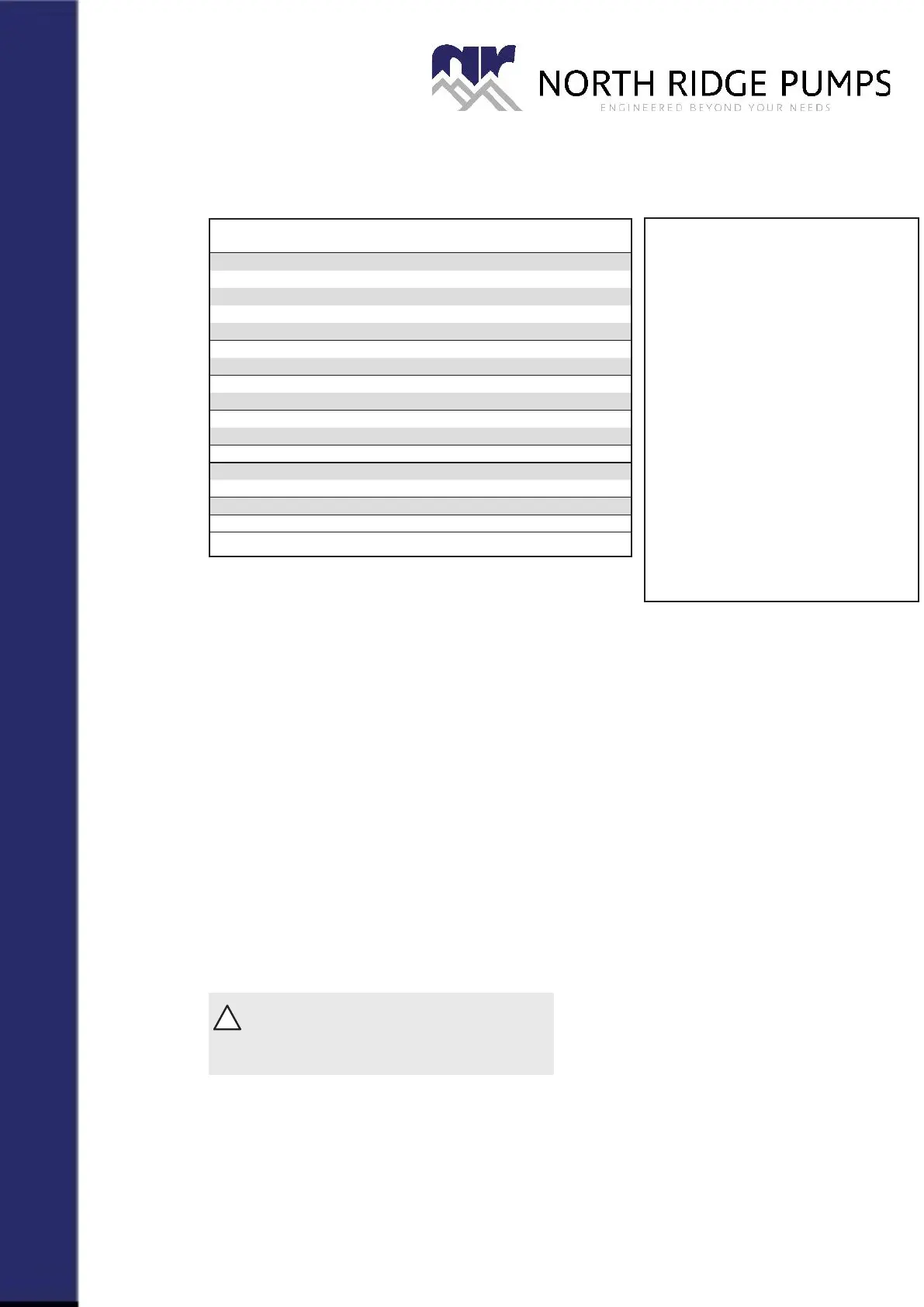

Recommendation:

For maintenance the following spare

part sets are recommended:

Set: To be used:

G057 Joint kit

For dismantling the pump.

G053 Minor kit

For service.

G054 Major kit

For repair after damage or greater

wear.

Ordering example:

For IMO-pump ACE 032N3 NVBP,

serial number 456789:

Shaft seal pos G050 p/n 194030

Valve element pos G070 p/n 189873

Item Spare Parts sets 025 032 038

G012 Rotor set CW-rotation (std)

Low lead-L3 190486 190485 –

Low lead-K3 – – 190482

Normal lead-N3 190487 190484 190483

High lead-D3 – – 192698

G011 Rotor set CCW-rotation

Normal lead-N3 190492 190491 190488

G050 Shaft seal-xVxx 194030 194030 194030

Shaft seal-xTxx 190495 190495 190497

G053 Minor kit-xVxx 190501 190710 190500

Minor kit-xTxx 190503 190712 190499

G054 Major kit=G012(G011)+G053+G070

G057 Joint kit-xVxx 190525 190714 190522

Joint kit-xTxx 190524 190713 190523

G070 Valve element 189873 189873 189873

125 Secondary seal xTxx 190469 190469 190468

Part numbers for pump size

Ordering code

Inspection of shaft seal

Excessively leaking shaft seals (more than 10 drops

per hour) should be changed without delay, as the

leakage normally will grow worse and cause addi-

tional damage.

In installations where unplanned shut downs must

be avoided, it is advisable to dismantle the pump for

a thorough inspection and thereby change out shaft

seal and ball bearing, every three years as a max

period.

It is recommended always to have the spares in-

cluded in minor spare part kit available.

Inspection of rotors

A quick inspection of the idler rotors can be made

simply by removing the rear cover. Note that the

driver must be deenergized and the pump hydrauli-

cally isolated before the rear cover is removed.

If a more thorough investigation is needed, proceed

as under ”Dismantling/Reassembly”.

Service intervals

The intervals for inspection and replacement of wear

parts vary greatly with the properties of the pumped

liquid and can only be determined by experience.

Pumping liquid which contains abrasive materials,

or liquid that is corrosive, will signicantly reduce

service life and call for shorter service intervals.

Wear will normally show as unnormal:

• Vibration

• Noise

• Loss of capacity

• Reduction in ow/pressure

• Leakage

If the pumps operating temperature ex-

ceeds 60°C let the pump cool off before

any service, maintenance or dismantling

work is commenced to avoid burn injury.

Product Specification Sheet

X-Cel House, Chrysalis Way, Langley Bridge, Eastwood, Nottinghamshire NG16 3RY

Tel: +44 (0) 1773 302 660 | Email: sales@northridgepumps.com | Website: www.northridgepumps.com

Loading...

Loading...