2

IMPORTANT NOTE

The importance of seal chamber priming cannot be overemphasized. Due to the prevalence

of seal damage and leakage caused by not filling the seal chamber with liquid before

putting a pump in service, this page is located at the beginning of this document.

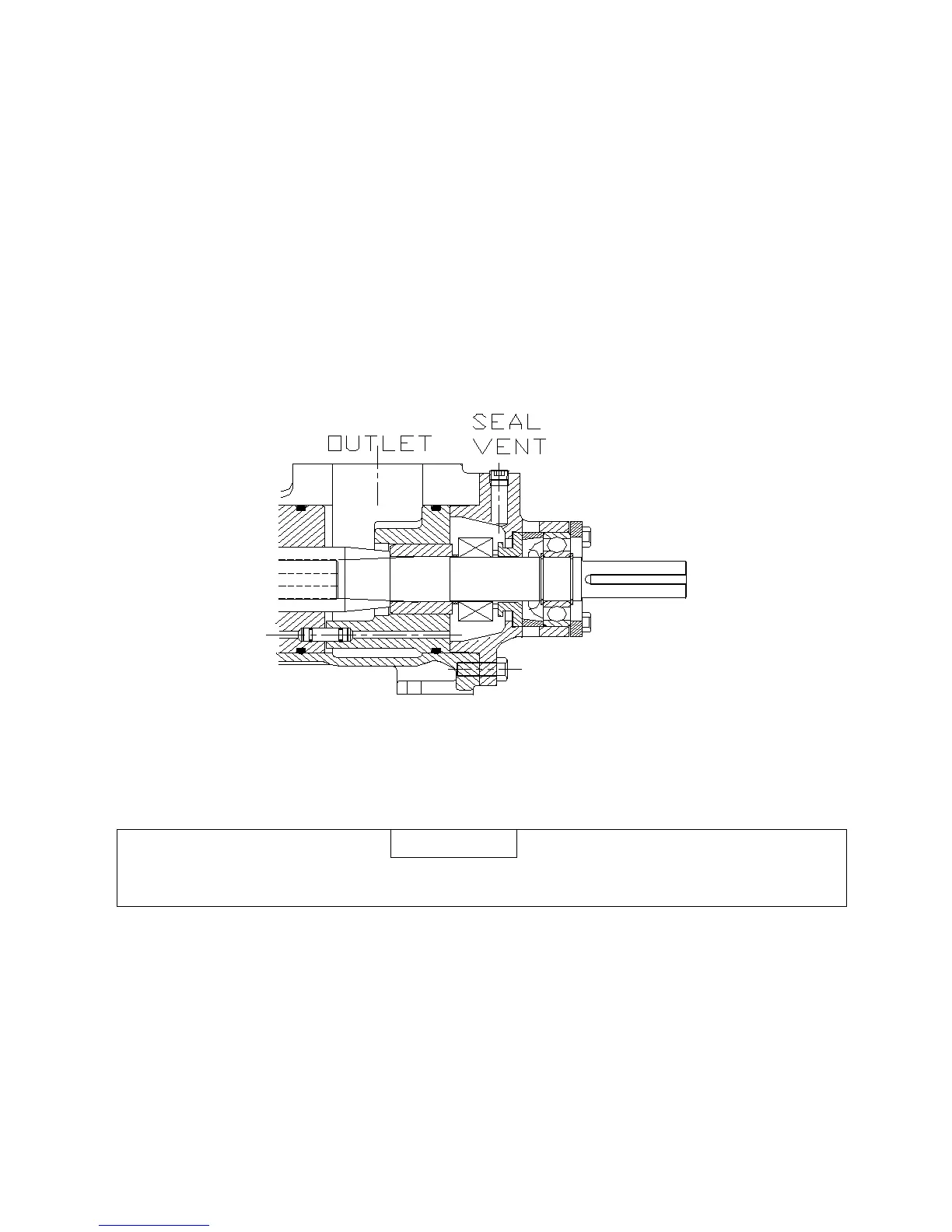

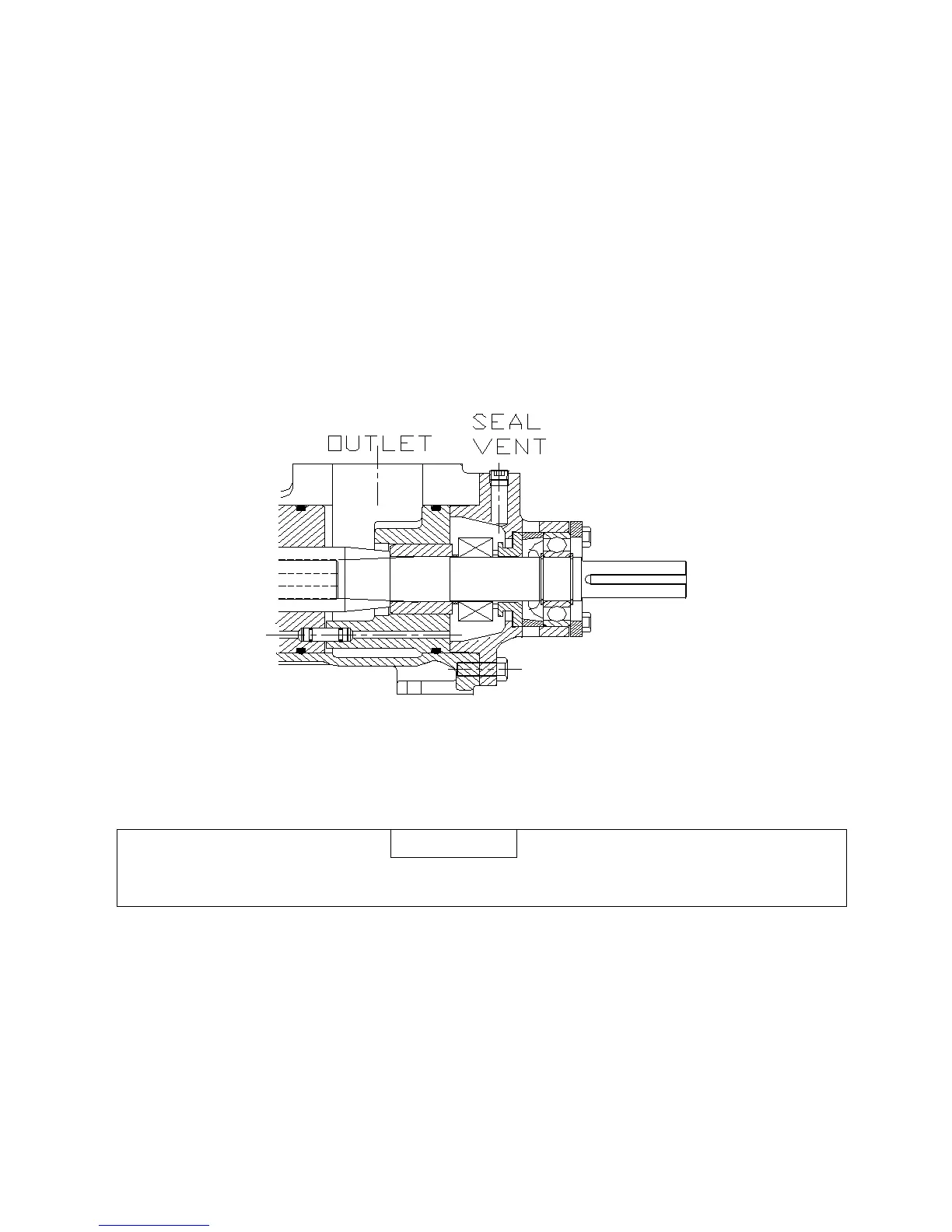

SEAL CHAMBER PRIMING

Fill mechanical seal chamber with liquid to insure seal does not start dry. This can be done by removing seal

vent set-screw and pouring liquid into vent passageway before opening pump inlet. Alternately, seal

chamber can be vented in situations where inlet pressure is above atmospheric by opening inlet and

discharge valves and then loosening seal vent plug to allow positive inlet pressure to push air out of seal

chamber until oil flows from it. See figure below.

Filling or Venting Seal Cavity Using Seal Vent

CAUTION

Failure to fill or vent seal chamber as described above may cause damage to seal running

faces which may result in seal leakage.

Loading...

Loading...