ASSISTANCE

19

GB

Service Manual

MOON - 2006

Linguage

English

Edition

2006.06.12

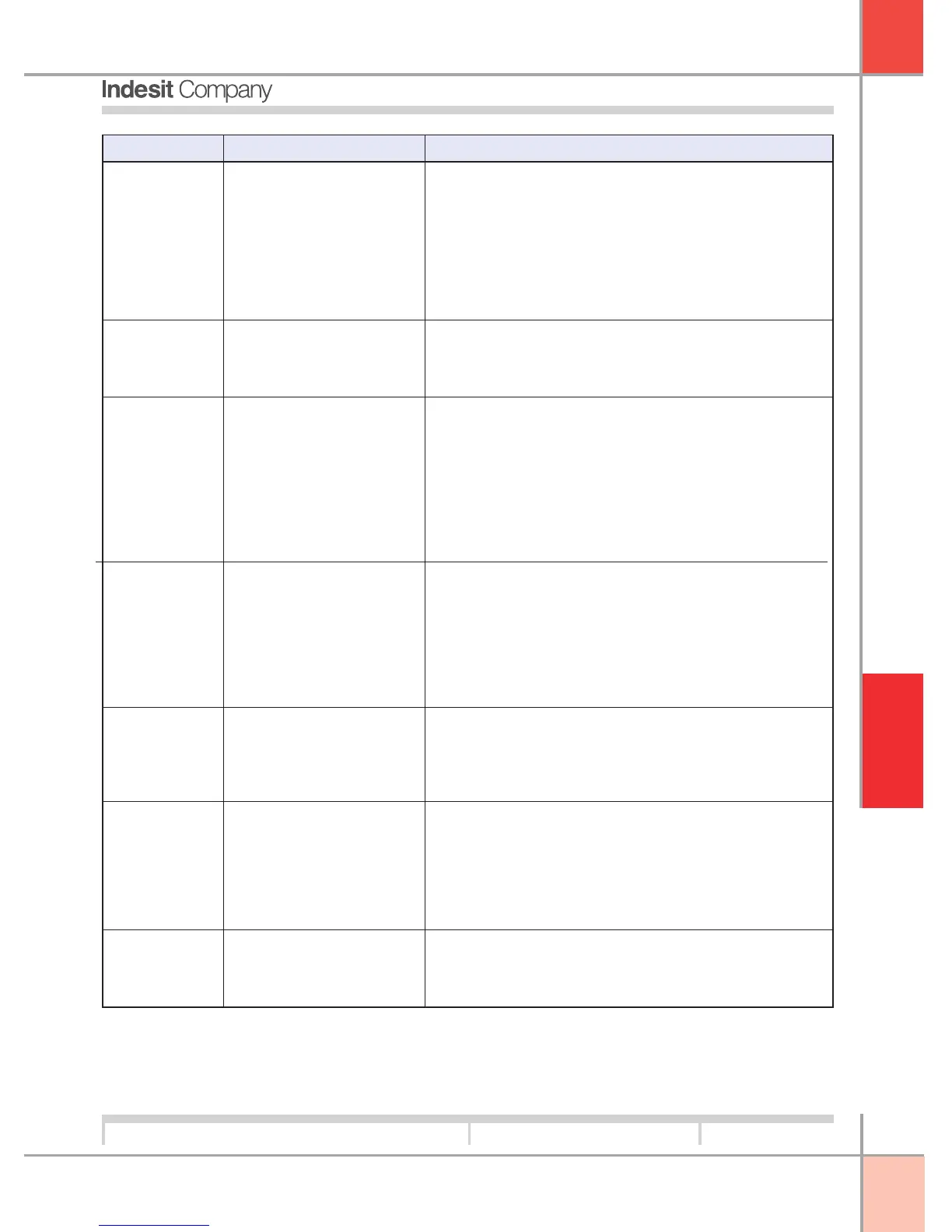

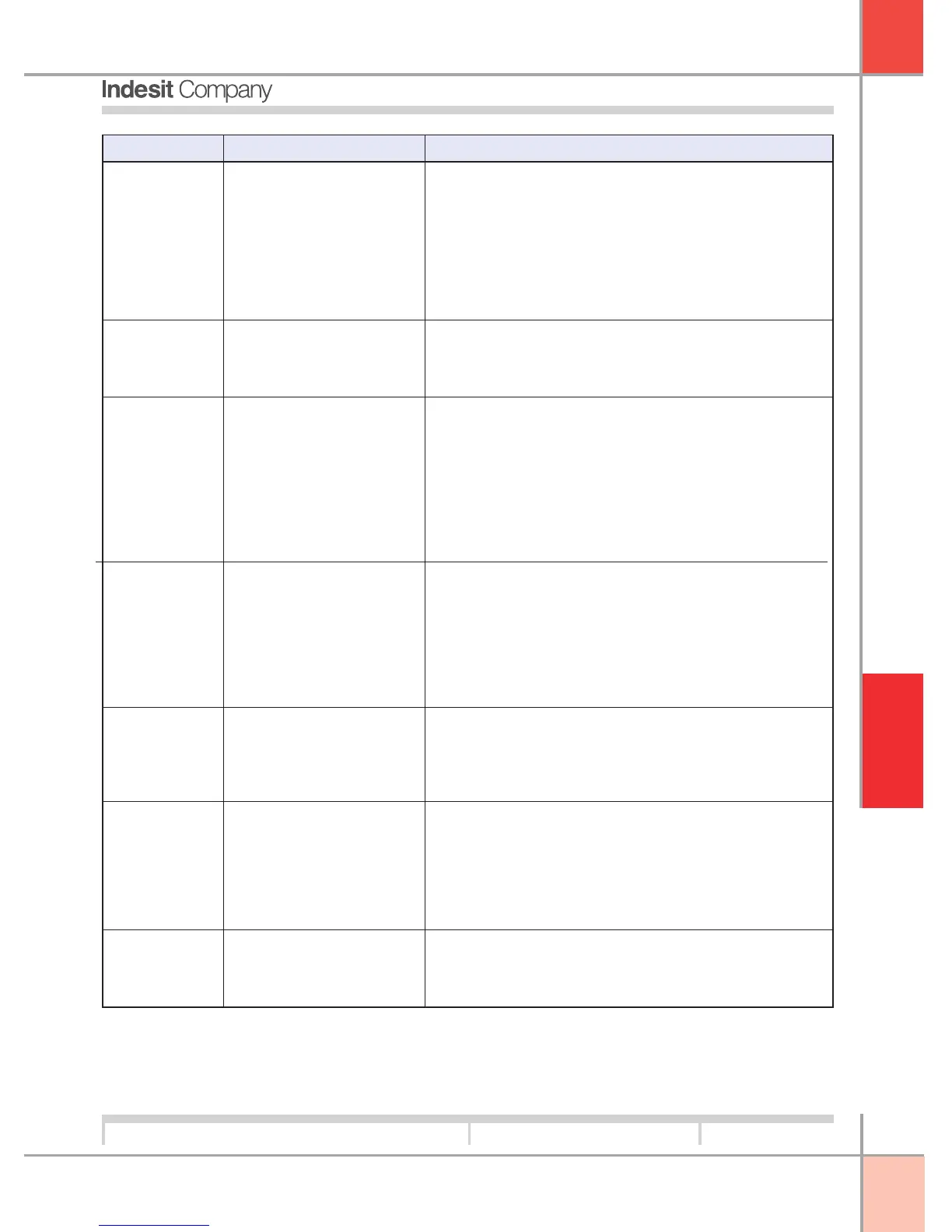

- Check effi ciency of contacts on connector J3 on PCB;

- Check condition of pressure switch by checking for impedance on

J3 wiring connector pins 2 and 4 (impedance should be measured

only with tub empty), pins 2 and 3 (impedance should be measured

only with water in tub) and pins 2 and 1 (impedance should be

measured only with water in tub to above the level of half-way up

the door window);

- High level of ambient humidity;

- In the case of PCB made with soldered EEPROM, renew PCB and

EEPROM;

- In the case of replacement PCB and EEPROM, check correct

insertion of EEPROM in PCB socket.

- Check effi ciency of contacts on connector J3 on PCB;

- Check condition of pressure switch by checking for impedance on

J3 wiring connector pins 2 and 4 (impedance should be measured

only with tub empty) and pins 2 and 1 (impedance must be present

only with water in tub to above the level of half-way up the door

window);

- Check wiring of connector J3/pressure switch;

- Replace pressure switch;

- Replace card.

- Check effi ciency of contacts on connector J9 on PCB;

- Check continuity of the pump on connector J15 pins 1 and 2 (for

machines with “Easy Door” door lock) or on connector J9 pins 8 and

9 (for traditional door locks), ensuring that the impedance value is

170 Ω;

- Check wiring of connector J15 (or J9)/pump;

- Renew pump;

- Replace card.

- Check effi ciency of contacts on connector J11 on PCB;

- Check continuity of connector J11/5-way connector of display

PCB;

- Renew main PCB;

- Renew display PCB.

- Check 230V power supply on wiring connector J4 inserted on PCB

between pins 2 and 3 (not when the machine is on stand-by), and the

presence of 230V output power supply from the door lock between

pins 3 and 1;

- Check door catch;

- Renew door lock;

- Renew PCB;

- Renew power PCB.

Wash heating element

relay contacts sticking

(signalled in presence

of empty condition) or

pressure switch sticking on

full condition (empty and full

signals simultaneously)

F08

F09

F10

F11

File setup error (EEPROM

not programmed or faulty).

Empty and full signal

missing simultaneously.

No pump feedback condition

detected (drain pump

disconnected or winding

interrupted).

F12

No communication between

display board and control

board

Communication error

between Microprocessor

and DSP (Digital Signal

Processor)

F18

F17

Door lock unfed/open

(traditional door lock, not

Easy Door)

FAULT CORRECTIVE ACTIONSCAUSE

Loading...

Loading...