Check the installation dimension between the spindle nose end face (5) and

the base body (1) against the size 15

+0.5

mm (in “Clamp open” position).

Observe the installation position.

Alternatively, the following procedure can be used!

If the installation dimension is not correct, turn the base body forward or

backward, until the setting dimension is achieved. Observe the installation

position.

7.

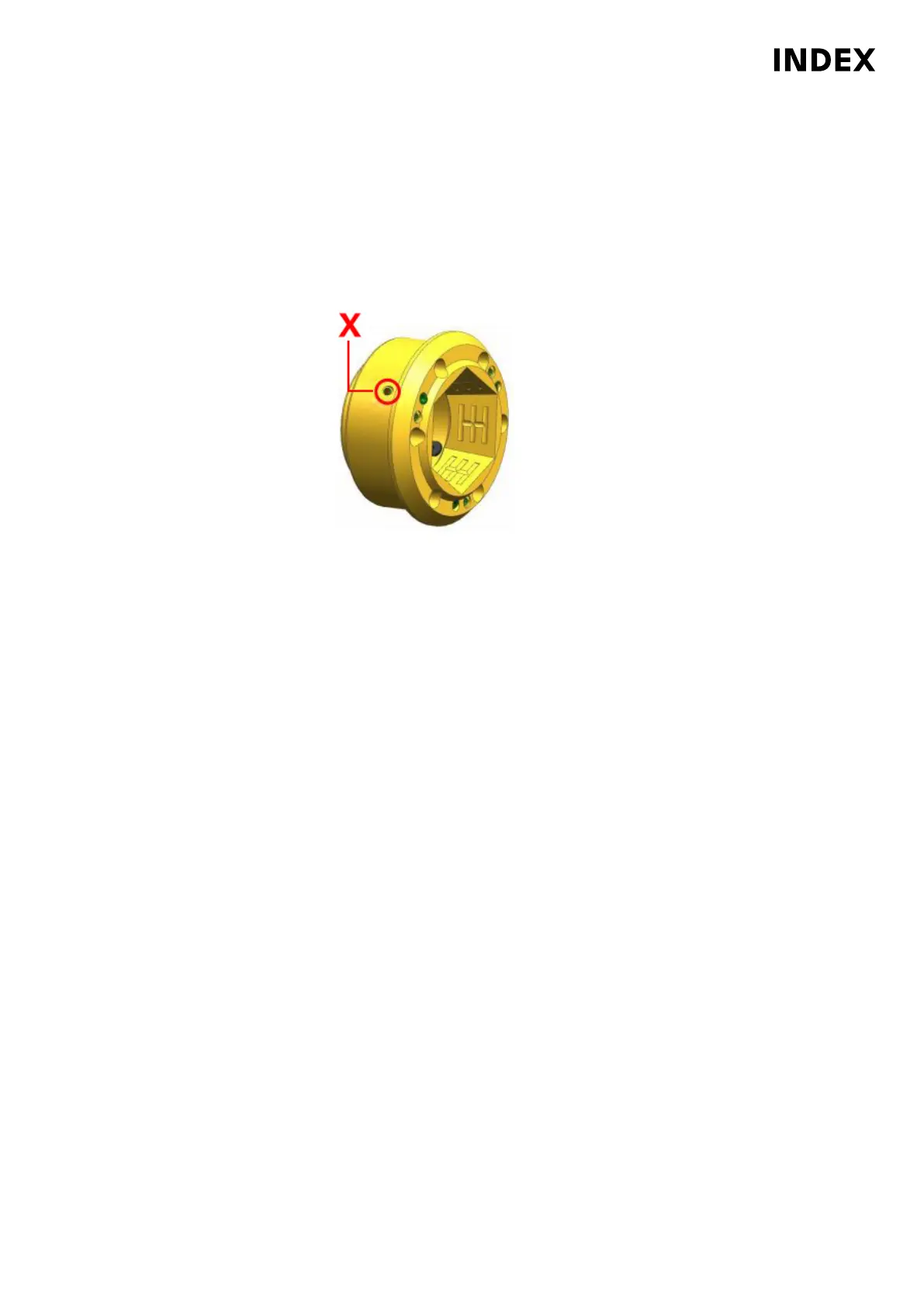

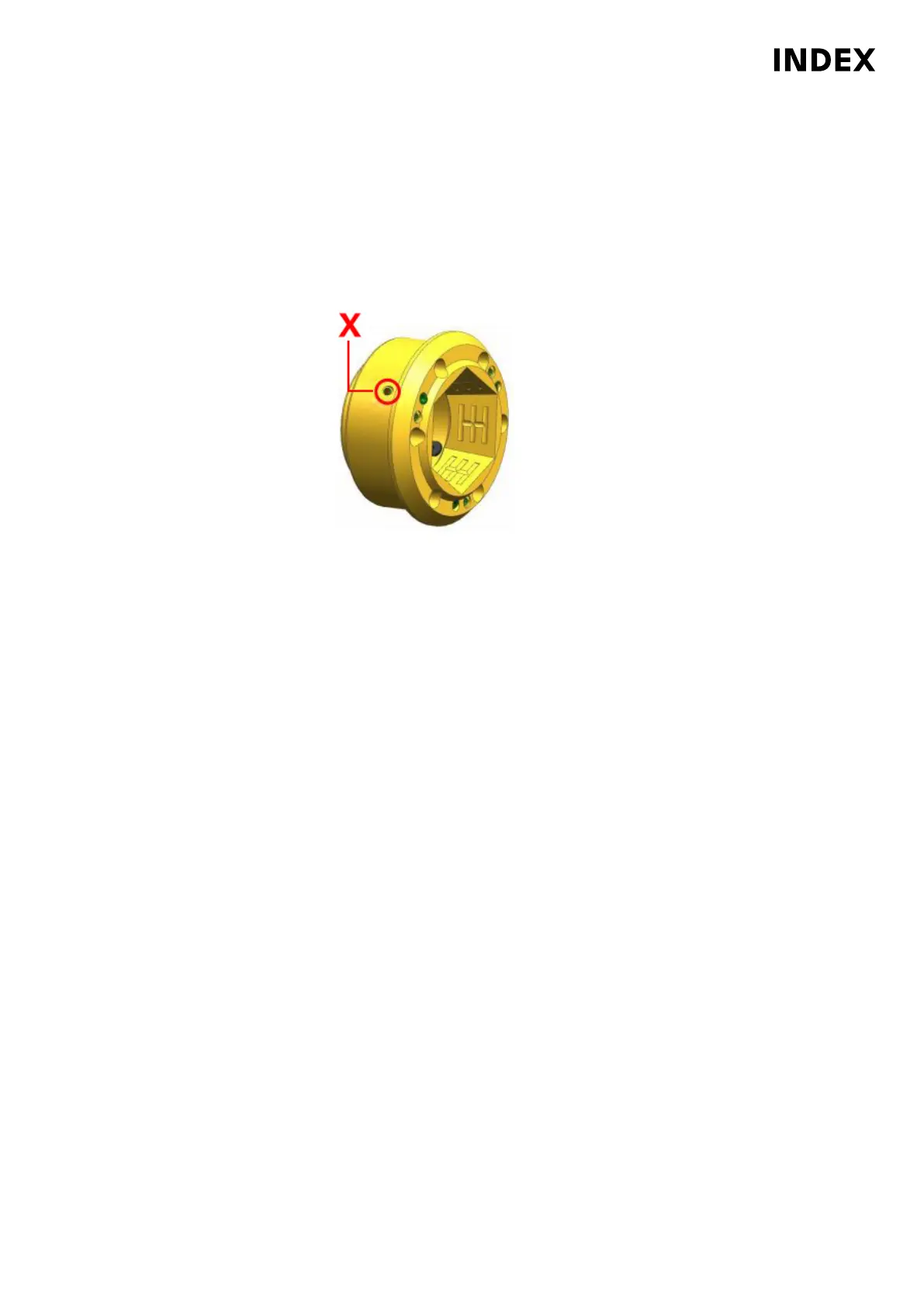

Example: Close TOPlus on cooling lubricant device through main spindle

X

Bonded (Loctite

®

221) set screw

Check the clamping element holder. Valid for all machines MS32-6.3, MS40-6

and MS40-8 with TOPlus clamping system, robot and cooling lubricant device

through the main spindle. Before reinstalling the clamping element holder,

make absolutely sure that the holes marked X are closed with set screws. The

set screws must be screwed down to the bottom of the hole and bonded with

Loctite

®

221.

8. Place the clamping element holder (2) on the spindle nose face (5) and screw

in 6 screws.

9. Tighten the 6 screws (3) crosswise to a torque of 14.9 Nm.

10. Insert collet (4).

11. Be sure to remove the spindle lock (device/locking pin) after finishing

the work.

Maintenance Summary - Care activities

43

Maintenance Instructions

MS40-6

DIM021EN - 03.06.2020

Loading...

Loading...