Do you have a question about the Ingersoll-Rand 7/170 and is the answer not in the manual?

Warning regarding potential health effects of diesel engine exhaust.

Manual contents, warranty disclaimers, and product specifications.

Details warranty periods for various equipment types and conditions.

Specific optional warranty terms for compressor airends and components.

Instructions for machine and engine warranty registration.

Explains standardized symbols used for warnings and instructions on machinery.

Details regulations and information regarding noise control for compressors.

Log for recording maintenance related to noise emission control systems.

Schedule for routine checks and maintenance of noise emission controls.

Essential safety warnings and general precautions for operating the equipment.

Hazards and safety measures associated with compressed air systems.

Information on hazardous materials used in the machine and handling precautions.

Safety guidelines for handling batteries and servicing the radiator.

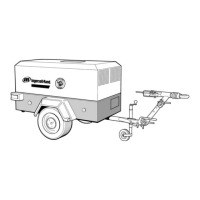

Illustrates the overall layout, dimensions, and access points of the compressor unit.

Technical specifications for compressor models, including air delivery and pressure.

Recommended oils and fluids for engine and compressor based on temperature.

Key technical specifications for the engine used in the compressor.

Pre-operation checks and procedures to ensure safe and correct startup.

Identifies and explains the functions of gauges, switches, and indicators.

Describes diagnostic indicators and fault alerts from the machine's control system.

Step-by-step instructions for safely starting and stopping the compressor unit.

Guidelines for selecting and using appropriate fuels, oils, and coolants for the engine.

Procedures and recommendations for the initial break-in period of the engine.

Chart detailing service intervals for lubrication and maintenance tasks.

Step-by-step guide for replacing the fuel filter elements.

General procedures and precautions for performing regular maintenance tasks.

Instructions for removing, inspecting, and replacing the compressor oil filter.

Procedures for inspecting, replacing, and maintaining air filter elements.

Guidelines for inspecting and maintaining the electrical system and battery.

Glossary of symbols and abbreviations used in system schematics.

Diagram illustrating the connection and interface between the wedge controller and the engine.

Wiring diagram showing the connections within the machine's harness system.

Lists recommended special tools for servicing electronic systems and connectors.

Catalog of electrical components with part numbers and quantities.

Identifies common engine problems, their causes, and remedies.

Lists common compressor issues, causes, and solutions for troubleshooting.

Information regarding the lubricator option, including safety and maintenance.

Details on the dual pressure option, its operation, and safety.

Information on the IQ system option, including safety, operation, and maintenance.

Guidelines on how to order parts, including descriptions and fastener information.

| Brand | Ingersoll-Rand |

|---|---|

| Model | 7/170 |

| Category | Air Compressor |

| Language | English |

Loading...

Loading...