Do you have a question about the Ingersoll-Rand Man Rider MR150K Series and is the answer not in the manual?

| Wire Rope Length | 150 ft |

|---|---|

| Air Pressure | 90 psi |

| Wire Rope Diameter | 3/8 inch |

| Rated Load | 1500 lbs |

| Capacity | 1500 lbs |

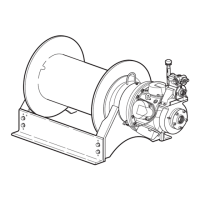

This product is an air power-driven winch for lifting a person in a lifting harness.

Contact information and addresses for Ingersoll Rand Kent and Douai Operations.

Details technical specifications including air system, motor, drum, and weight.

Information on product design factor and traceability/type approval certification.

Instructions for securing the winch to a suitable foundation and ensuring stability.

Guidance on proper air supply requirements, including filters, regulators, and lubricators.

Consulting experts for appropriate wire rope type, considering design factors and ratios.

Procedures for securely feeding and anchoring wire rope onto the winch drum.

Techniques for ensuring proper and tight winding of wire rope onto the drum.

Describes the throttle control for motor speed and direction, and control types.

Procedure for activating the emergency stop and resetting the winch system.

Details the automatic disc brake and automatic drum band brake operation.

Daily visual checks by operators and periodic visual inspections by trained personnel.

Detailed inspection requirements beyond daily checks for ongoing winch monitoring.

Annual replacement of oil in the reduction housing for optimal winch performance.

Cleaning and coating bearings and seals with grease after disassembly for protection.